Virginia Tech recently announced the Additive Manufacturing Grand Challenge where students will be encouraged to come up with new designs for remote piloted – they mean drones, but I guess they don’t want to use that word – air or ground vehicles constructed entirely, or almost entirely, out of 3D printed parts. The drones need to be able to be quickly assembled in the field by the military in war zones or on-site rescuers during natural disasters to aid in the search for survivors.

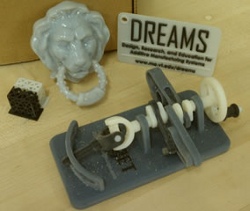

The competition is being sponsored by the Air Force Office of Scientific Research (AFOSR), the National Defense University, Robotic Research, and the Stiefel Family Foundation, Virginia Tech’s DREAMS Lab and Mechatronics Lab. The contest is aiming to encourage young engineers to consider additive manufacturing and 3D printing when designing new products.

“[The competition] allows us to showcase to the broader community our students’ talent, ingenuity and familiarity with emerging technologies such as additive manufacturing,” said Christopher Williams, head of Virginia Tech’s DREAMS Lab. “We see this spring’s grand challenge competition as a pilot for a larger, multi-university competition in the coming years.”

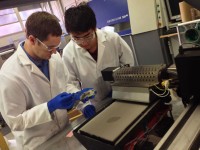

The competition will challenge students to create their vehicles using as many 3D printed parts as possible and will only provide standard non 3D printed components like off-the-shelf electronics kits, receivers, batteries and small motors. Harsh real-world conditions will be simulated by having the participants navigate their vehicle through an obstacle course in order to photograph four different waypoints. The finished vehicles will be judged based on how well and how quickly they navigated the course, how well they used additive manufacturing in the construction of their drones, the amount of components that are 3D printed and the time required to print and assemble.

The Air Force is providing the majority of the funding for the contest and is looking to expand it into other colleges, tech schools, high schools, maker groups and corporations.

“Additive manufacturing is a potential game-changing manufacturing technology for our military platforms.” said David Stargel AFOSR division chief. “The Air Force Office of Scientific Research is excited to help lead the development and education of our future engineers through this Grand Challenge competition on the design of additive manufacturing.

Source: Virginia Tech