Scientists from the University of Southern California (USC) are using 3D printing to investigate the the potential of smart metamaterials. Adding the brick-and-mortar structure of high-strength nacre (aka mother of pearl) to electrically conductive graphene, the team have demonstrated the ability to create self-sensing armor. Proven in a small-scale experiment with a LEGO figurine, a recent paper highlights how the process could be used to monitor damage to the body.

According to the study, “Such a new fabrication technique could enable the design and fabrication of the smart structures that are lightweight yet strong for various potential applications in biomedical, aerospace, transportation, sports, and military industries.”

Clip demonstrates the sensing capabilities of USC’s 3D printer material. Clip via Science Advances, Supplementary Materials

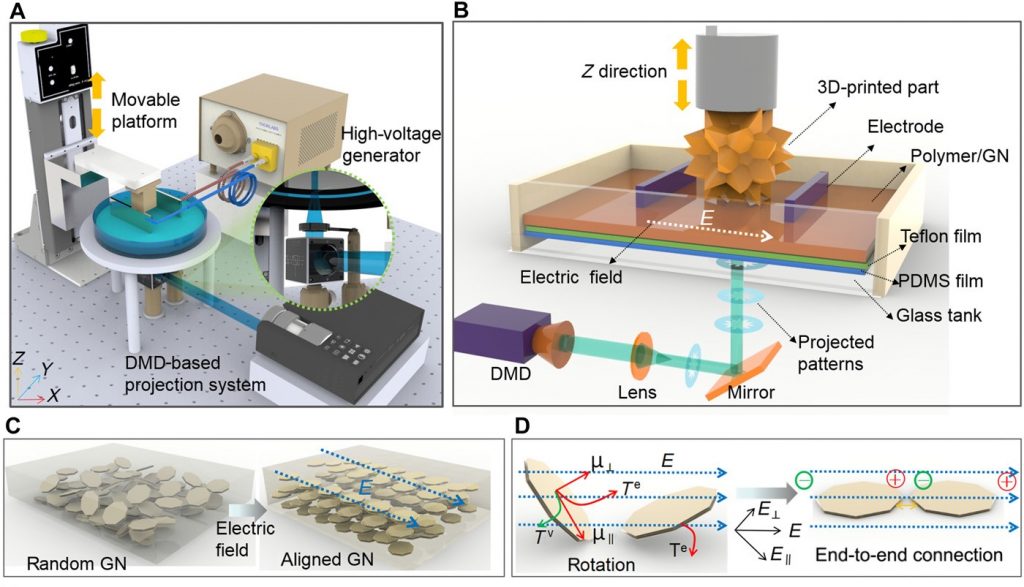

Electrically assisted 3D printing

The USC team’s smart-armor experiment is undertaken using a custom vat polymerization 3D printer and resin. At the bottom of the vat, the team inserts a two-layer teflon/PDMS film and an electrode for the purpose of generating an electric field. The resin the team uses is premixed with graphene nanoplatelets (GNs).

3D printed regularly, the GNs in this random are randomly arranged, giving variable properties to the overall structure. In the USC team’s approach, however, they use the electric field to uniformly align these particles layer by layer, resulting in a nacre-like structure.

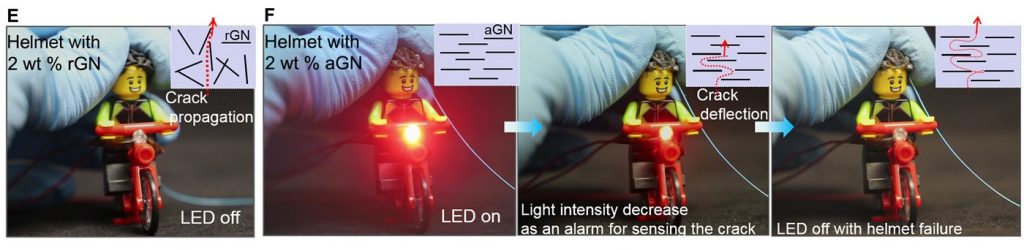

Mechanically, the fracture toughness for this GN-reinforced material is significantly higher than polymer alone, in some cases increasing the MPa by 115%. As a means of testing this property, the team conduct a mini-helmet experiment.

Developing a spidey-sense

Linked up to a small red LED, the USC team’s 3D printed helmet is designed to “sense” pressure from above. As compression increases, the intensity of the light decreases, signalling its potential to crack. Finally, when the helmet is forced to crack, the LED switches off, alerting failure of the device.

From this experiment, it is easy to see how such a system could be used as a preventative measure for the failure of sportswear, armor, and even certain components.

A match made in heaven: 3D printing and bioinspired design

For its strength and resilience, nacre has been the inspiration behind many alternative materials development projects. The Danish Council for Independent Research Technology and Production Sciences previously funded a study into the potential of such a material. And Silvan Gantenbein, a PhD candidate at ETH Zürich cited the material in the development of a new liquid crystal polymer (LCP) filament for 3D printers.

A paper discussing the result of USC’s “Electrically assisted 3D printing of nacre-inspired structures with self-sensing capability” is published open-access in Science Advances. It is co-authored by Yang Yang, Xiangjia Li, Ming Chu, Haofan Sun, Jie Jin, Kunhao Yu, Qiming Wang, Qifa Zhou and Yong Chen – the same team that previously used 3D printing to explore the way some tropical plants manipulate water.

Vote for your Research Team of the Year in the 2019 3D Printing Industry Awards.

For more of the latest research news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in academia? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows the USC team’s LEGO test dummy wearing broken 3D printed helmet. Photo via Science Advances