Scientists at the University of Michigan have developed a high speed 3D printing technology that can be scaled to achieve the production of large objects.

Tipped to be 100 times faster than other commercially available technologies, the technique is also capable of rending a 3D object with just a single flash of light rather than layer by layer. As such, UMich researchers are calling the system:

“one of the first true 3D printers ever made.”

Taking on Carbon CLIP

UMich’s high speed 3D printing process is a vat polymerization technique based on SLA. Considering the set up of an SLA 3D printer, (with the light source below a vat of resin) one of the limitations of such processes is the resin’s adhesion to the projection window at the base of the vat. As a result, SLA 3D printing is conducted at speeds lower than its potential.

In continuous liquid interface production (CLIP), the method patented by California-based 3D printer provider Carbon, an oxygen permeable projection window is used to create a thin polymerization-free area in the resin at the bottom of the vat. This prevents the resin from curing and sticking to the projection window, enabling Carbon to reach the high production speeds that it’s famous for.

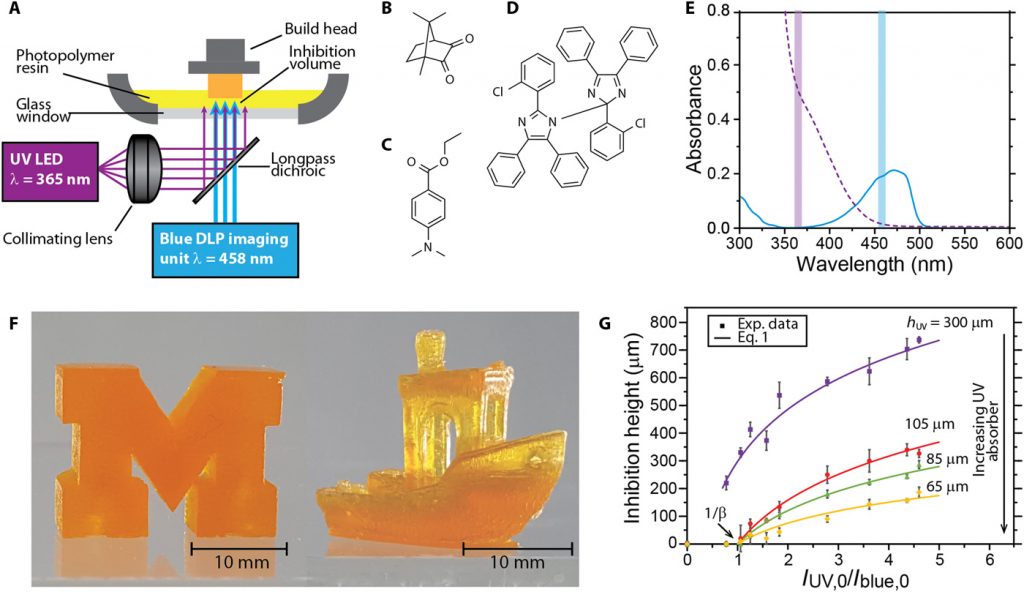

UMich’s method takes an alternative approach. In place of an oxygen membrane, its 3D printer uses a dual light source.

Inside the UMich high speed 3D printer

The UMichigan 3D printer contains two different colored lights with respectively varied wavelengths – one ultraviolet (UV), and one blue. By using a resin mixture that contains both photoinitiators and inhibitors, these lights can be tuned to start or stop the curing process as required.

In the example given by UMich researchers, blue light is used to selectively initiate solidification, and UV is used to prevent it. This creates the polymerization-free space needed above the projection window.

With this technique, the UMich team has been able to achieve print speeds of approximately 2 m/hour. By further varying the intensity of the light source, the method is also capable of performing “surface topographical patterning in a single exposure/layer with no stage translation.”

Referencing this ability Mark Burns, UMich professor of chemical engineering and biomedical engineering and co-lead of the research, says, “It’s one of the first true 3D printers ever made.”

Broadening opportunities for additive manufacturing in mass production

In comparison to the CLIP oxygen membrane, the combination of lights in the UMich 3D printer allows a much thicker void of material in the vat where polymerization doesn’t occur. This therefore means that stronger, more viscous, materials can be used in the continuous 3D printing process and, as stated in the results of a paper detailing the method:

“By eliminating the need for thin, O2-permeable projection windows, this process has the potential to be scaled for rapid production of very large objects.”

In addition, the authors believe that method could unlock further potential for additive manufacturing in mass production. Timothy Scott, UMich associate professor of chemical engineering and co-lead of the project, explains, “Using conventional approaches, that’s not really attainable unless you have hundreds of machines.”

Hitting the market

A full discussion of the new UMich 3D printing method has been published online in Science Advances under the title “Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning.” Its authorship is credited to six researchers in total, namely Martin P. de Beer, Harry L. van der Laan, Megan A. Cole, Riley J. Whelan, Mark A. Burns, and Timothy F. Scott.

Of the researchers listed Scott, van der Laan and Cole have all been named as inventors on a patent relating to the technology filed by UMich on 20 February 2018. According to the university, there are a further two patent applications in place to protect the technology, and from here it seems that the team plans to commercialize the technology as Scott is looking to set up a startup company.

For more updates on this technology as it progresses into commercialization subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Nominate the University of Michigan team and more for the 2019 3D Printing Industry Awards. And, for career opportunities, search 3D Printing Jobs.

Featured image shows a University of Michigan “M” 3D printed by the new high speed fabrication technique. Photo by Evan Dougherty/Michigan Engineering