Researchers from the University of Huddersfield in the UK are developing a new language to help streamline the additive manufacturing process.

According to Dr Qunfen Qi, a research fellow at Huddersfield’s EPSRC Future Advanced Metrology Hub, “The research can provide a smart language that enables designers, [additive manufacturing] engineers and inspectors to truly communicate with each other in an intelligent, robust and productive way.”

Through improving these connections across the whole production chain, it is expected that the universal language will enhance the productivity of 3D printing, with implications for greener manufacturing.

Rewriting the rules of manufacturing

At present, digital means of 3D model sharing and processing are in abundance. As explained in the abstract of a paper co-authored by Dr. Qi, “Exchanging computer-aided design (CAD) model data among heterogeneous CAD systems is indispensable for collaborative product development. Currently, the industry mainly uses the standardized neutral files-based methods to implement such exchange.” For 3D printing this is, essentially, the long outdated .stl format, .obj files and others.

The abstract continues, “The coexistence of different types of methods has generated a series of controversies and questions within the industry and the academia,”

“Yet, can the neutral files-based exchange methods completely implement model data exchange among heterogeneous CAD systems?” i.e. Are these files adequate at communicating with design platforms, engineering programs, and inspection software?

The simple answer is: No. And many software companies are seeking to provide a “one-size fits all” solution for communication between these areas of production.

Improving additive manufacturing workflows

Dr. Qi’s work for additive manufacturing relies on the principles of mathematical category theory. Dr. Quin expects that such research “will greatly improve the process repeatability and part-to-part reproducibility, and significantly reduce power usage and failure rate, lower the cost of production and make a more environmentally-friendly manufacturing technology.”

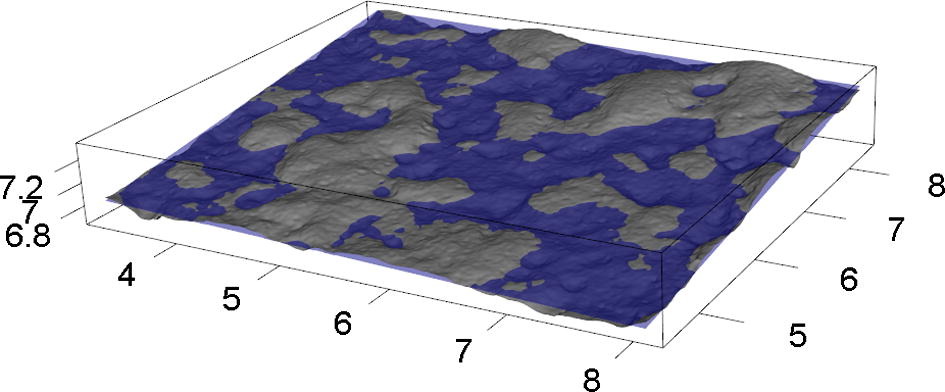

Over the course of studies using this mathematical structure, Dr. Qi has designed a custom language for Rolls-Royce to design and measure surface texture.

The aim now is to create a more universal smart language that can be independently employed regardless of application or industry.

Dr. Qi presented the current work at the 15th CIRP Conference of Computer Aided Tolerancing, in Milan, Italy. The published results are yet to follow.

To stay up to date with all the latest additive manufacturing research sign up to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Seeking a career in engineering? Join 3D Printing Jobs now.

Featured image shows Progressive Mesh Restoration of a Stanford Bunny – the computer graphics 3D test model that has now also become a test for 3D printers. Image via tobijkde on YouTube