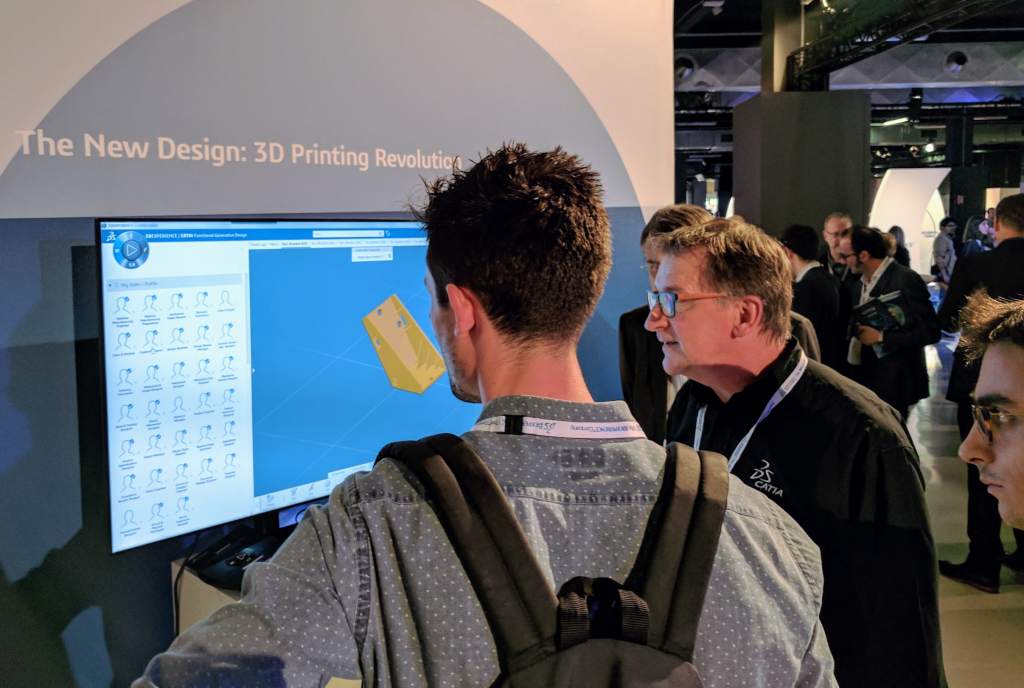

This month’s Design in the Age of Experience event at MiCo Congressi in Milan brought together 400 managers, designers and engineers. 3D Printing Industry were in attendance at the conference and expo organized by Dassault Systèmes, and had the opportunity to speak with the CEO and other executives of this leading global software company.

Dassault Systèmes was founded in 1981 to develop the CAD software initially worked on by parent company, Avions Marcel Dassault. When the first commercial CAD packages began to appear in the early eighties, typical system requirements were a 16-bit computer, with 512 kb memory and 200 Mb storage – the average price was $125,000.

Now with software such as CATIA and SOLIDWORKS, Dassault Systèmes tools are used to design and produce 90% of all cars. Furthermore, every 2.5 seconds somewhere in the world an airplane designed using these tools takes off. At SOLIDWORKS World in 2010, Dassault were the first major company to discuss how cloud-based computing would change the way designers and engineers used software.

A strategic Marketplace

With this history, when Bernard Charlès, Dassault Systèmes’ Vice Chairman, Chief Executive Officer says software platforms connected to a 3D printing network are, “going to completely change the manufacturing world,” those looking for an insight into the future of engineering would be wise to listen.

The CEO says, that one problem in today’s manufacturing world is, “over capacity and overly rigid systems.” This means, “the economy is too rigid compared to the need for innovation.” One way Dassault is tackling these problems is with their Marketplace solution, which 3D Printing Industry previewed last year.

The Marketplace is an, “industrial ecosystem of Designers, Engineers and Production planners with Additive Manufacturing Service providers” and is currently in an invite only beta phase. Bernard Charlès says, “the Marketplace is very strategic – we will offer much more than 3D printing.”

3D printing introduces a fundamental ingredient

I asked Pascal Daloz, Executive Vice President, Brands and Corporate Development about how Dassault Systèmes are working with additive manufacturing and the barriers to wider adoption. “When I went to engineering school, they gave me the books of materials and you chose one. Then you have to live with that material in the product forever,” he says.

“3D printing is introducing a fundamental ingredient” for designers, “the ability to design materials and this is unprecedented,” Daloz explains.

For example, lattices or types of geometries that are only possible with 3D printing. So these aspects need to be covered by design, and the standards are not there. So what are we doing? We work with all the 3D printing companies in the world.

Daloz tells me about a visit to Desktop Metal prior to this week’s launch, “I’ve seen it working, they are basically providing desktop 3D printers for the office environment that can 3D print metal. This is truly amazing.”

Through the 3MF consortium (of which Dassault are a founding member) and also by working in collaboration with 3D printer manufacturers the company, “want to accelerate innovation.” Daloz explains, “We want to be ahead of the curve. We can not wait for the standards to mature, and we want to invent the future which is the the best way to predict it right?”

Co-operation with additive manufacturing OEMs

During the Milan event, 24 in-depth sessions were dedicated to Design Experience, Social Collaboration, Functional and Generative Multiphysics Design, IoT and many other emerging and leading-edge topics in the community of innovators. Gian-Paolo Bassi, CEO SOLIDWORKS gives more details about why, “co-operation with OEM’s matters.”

We worked with Cincinnati and their Big Area Additive Manufacturing (BAAM). Designing together to connect to the platform and to be able to directly take information and cement it inside SOLIDWORKS. This is why we are embedded in the design in SOLIDWORKS to allow for perfect additive manufacturing. You see the announcement we’ve done with Airbus and with Safran. What we learned from those companies is that there is a climatic change in the way we think about design. What was yesterday an assembly, is today one part.

This a profound change in the technology that takes a profound change in the methods to build, for example, a complete airframe.

Expanding and propagating 3D printing services

The SOLIDWORKS CEO explains more about how the Marketplace works, “If you are a designer or a company and you need to print something, you connect to the marketplace. It is fully cloud based, then we connect you to companies who can make the 3D print for you. The difference with what is on the market today is that the whole chain has been tested, in terms of extreme quality. So this is a new way to expand and propagate 3D printing services.”

Philippe Laufer, CEO at CATIA, gives further details for the motivation behind the Marketplace as a way to connect all the stakeholders in the 3D printing industry. He says, “this is the easiest way, you just have to declare yourself, you provide the services you want – designer, manufacturer or machine builder whatever and automatically the system connects natively to the geometry.”

“The supply chain will not exist as it does today”

Wrapping up an insightful discussion between the executives, Bernard Charlès, Dassault Systèmes CEO, says “We going step by step, we are now connecting with everything, basically it will change the supply chain.”

“The supply change will not exist as it does today,” says the CEO, “because you basically trade IP, and you trade work. It is a very different model and we are taking it very seriously.”

Dassault Systèmes has a vision of 2 business streams, “one of which is transaction based, and one of which is software based.” The CEO says, “We are already building a business where the software used on the platform for trading will be free, and the revenue will come from the transaction.”

This means you can expect software on our platform that will never be sold, because it will be so unique to optimize things in a way that we will not offer it for sale, but on the cloud as a transaction. So it’s a big plan and we have tested it for the last 5 years in different areas.

3D Printing Industry are looking forward to seeing this plan come to fruition and it appears so are our readers. Readers nominated SOLIDWORKS as the software of the year in our 2017 3D Printing Industry Awards, you can make your own vote here.

Interviews with leaders in the additive manufacturing sector, including Fried Vancraen of Materialise, Vyomesh Joshi of 3D Systems, Shane Wall, CTO at HP and Joe DeSimone of Carbon are some of the many available on our site.

Featured image shows Bernard Charlès, Dassault Systèmes CEO thanking Gian-Paolo Bassi, CEO SOLIDWORKS, Philippe Laufer, CEO CATIA and Pascal Daloz, Executive Vice President, Brands and Corporate Development [R-L]. Photo by Michael Petch.