HP Labs was founded 50 years ago this week, I sat down with the CTO of the ‘original Silicon Valley start-up’ to find out about plans for the next half century.

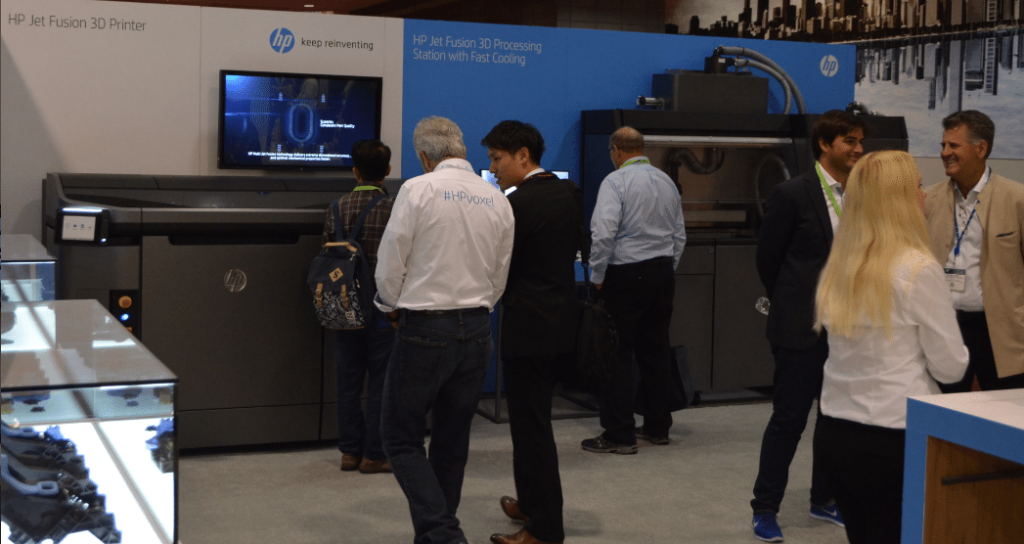

Throughout this year, analysts have cited HP’s forthcoming entrance into the 3D printing market as a reason why companies may have deferred investment. In development for 10 years and lifting the veil of stealth in 2014 (with a few earlier hints) HP’s Multi Jet Fusion (MJF) 3D printing solution will be available to a wider audience next month.

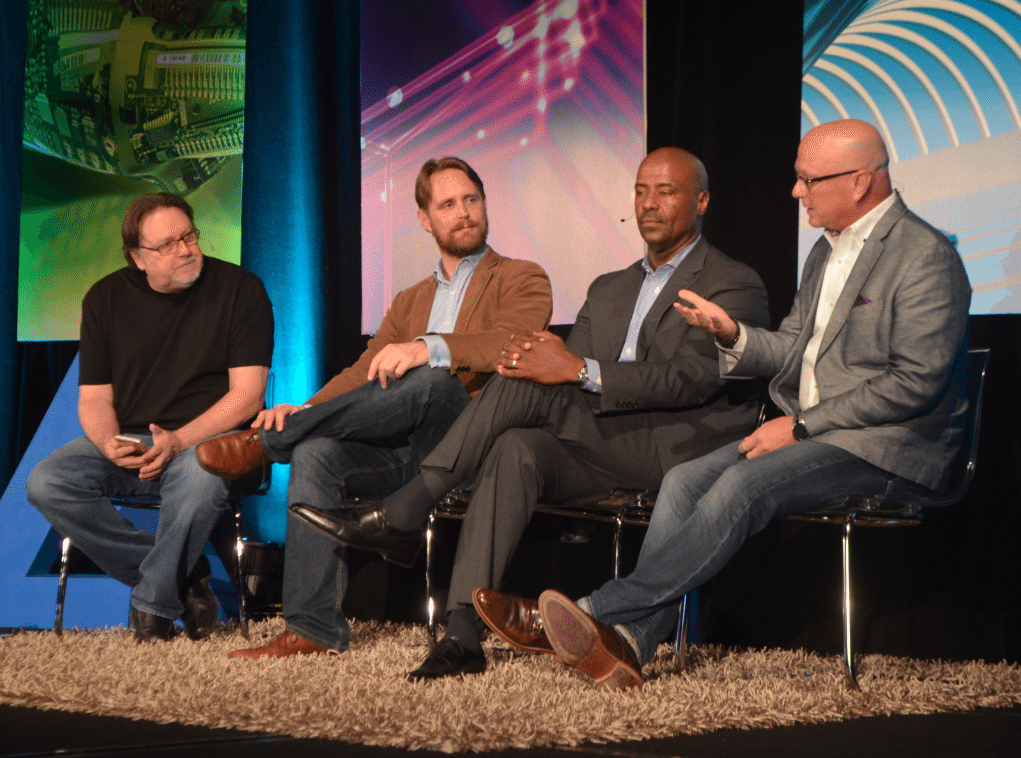

While already in use by a select few partners, including BMW and Nike, when MJF fully launch competition across the industry is set to heat up. Regarding the timing of HP Labs’ market entry Shane Wall says, “We didn’t come in late, what we said is when we entered this market we wanted to do something that was absolutely disruptive.”

3D Printing: A digital furnace

In his role of Chief Technology Officer, Shane Wall has spoken before about how 3D printing and other technologies such as immersive computing are transformative or disruptive technologies driving the next industrial revolution. HP refer to the increasing connection between the physical and digital world as ‘blended reality,’ and the company have a knack for interesting turns of phrase, such as describing MJF as a ‘digital furnace’ in one recent promo video.

Wall tells me, “It wasn’t good enough to come in and be 10% better, 10% faster. We wanted to come in and do something significant.” To this end MJF, “solves 4 of biggest issues in printing today.” These issues are speed, quality, cost and materials. The CTO describes how HP Labs address each of these areas,

First, Multi Jet Fusion is at least 10 times, and in most instances 100 times, faster than any technology out there today. The second is cost, [MJF] does it at 50% of the part cost of existing capabilities that are out there today. Third, it does it at a quality level not attainable, that quality level is achieved by operating at the voxel, a 3D pixel essentially, and then being able to change all aspects of that [voxel] to create parts that you could have never created before. The fourth reason is that it’s open. It’s an open system. Other people can put materials in, other people can bring in software and applications and so you end up with a complete ecosystem that you’ve created.

On this final point, the question of an open system, it is important to clarify. HP Labs have an “existing set of specifications about what materials can go in” says Wall. This means material developers must undergo “a qualification process so that the material can be qualified against the machine itself.” The rationale for this is one of safety according to Wall; think about who is more likely to be named on any future lawsuit brought about by issues with materials. Is it the company with a multi-billion market cap, or the small feedstock start-up? “It’s us right!” says Wall.

Putting the claims to the test

The other claims regarding speed and quality will be put to the test soon enough. From a practical perspective the innovations of HP appear able to make good on their promises. Ink jetting is well suited for scaleability and Wall explains the key innovations in the Multi Jet Fusion process. “There are actually 3 pieces to it,” he says. Firstly MJF “operates on a powder bed and from that standpoint may be somewhat similar to SLS.” The similarity ends there as the HP 3D printer can, “fire additive drops on top of the powder bed in a parallel fashion.” The technique uses “a print bar that can fire 320 million drops per second on top of the powder bed, and we can do that in one pass.”

This means the full layer is laid down in one swift movement. A second pass of the print head, or bar in this case, introduces a fusing agent. “The innovation is really operating in a parallel level, doing it with an additive on top and then a fusing agent” says Wall. This means that speeds greater than the, “serial process of a laser tracking a bed of material” are possible.

Post-processing 3D printed parts can be a chore, as anyone familiar with the industry will tell you. Several companies are tackling this issue in novel ways, including HP Labs. “We automated a lot of the backend about how you do post-processing,” says Wall.

There are 2 pieces to it. One of them is, you have to optimize the bed that you use. In other words, you have a bed and you want to be able to pack the parts in there as densely as possible. We have algorithms around software by which we do that. Once it’s built you essentially have the parts in a cake, and so that comes out into an automated machine that is a post-processing machine. It essentially de-cakes the parts, it recycles all the unused material and pulls it back in to be used later and it cleans the surface of the parts.

Moving forward to Metals

In terms of materials, the first MJF will launch, as announced, with a single color. The next iteration in the “following year, will bring in a few features. The most prominent we speak about is probably color” says Wall.

While the “initial product will focus on plastics and polymers” which “if you look at the market today that is the bulk of the market,” HP are investigating “4 different methods” to expand into the fastest growing segment, that of metals. Currently research is underway, “taking our core technology and figuring out how we can use it in the metal space” says Wall.

On the GE takeover bid Wall says, “it creates a competitor for us and that’s fine. I think it helps advance the state of the art, but it really validates the market.” I ask whether he shares the concerns of some in the industry that GE may seek to close off the 3D printing technology acquired in the takeover and reserve it to grant a competitive edge to themselves and their partners. “That’s hard to tell, what are they going to do and what their exact strategy is,” he replies.

Conversely, HP has worked out their strategic vision in no uncertain terms. “The way we look at the world at HP Labs is maybe a little different than some do” Wall tells me. This involves looking, “purposefully 30 years in the future.”

We don’t try and look at the technologies we have and how can we advance that technology and where can it go. What we try and do is step back and look at where society is going. It’s interesting when you do that because you start looking at things like urbanization and what happens when you have highly dense cities. Your ability to get goods in and out becomes constrained; your ability to manage energy becomes constrained.

Further consolidation and take-overs in the 3D Printing Industry

In the mega-cities of the future, “with hyper globalization, expansion of global reach and an expectation that things become instantaneous” HP Labs, “extract the problems that need to be solved.” 3D printing for the company is a solution to these problems and will play a key role for the, “fundamentally different way in which we make, in which we design and build and manage our products.”

After this week’s birthday celebrations are finished, HP Labs begin the next stage of their journey into “digital manufacturing.” A favorable market reaction may trigger the devaluation of rival 3D printing stocks as customers begin to order machines from HP rather than established 3D printing companies. Interestingly this may have benefits for HP Labs beyond the immediate additional income.

With rivals trading at lower valuations any possible takeover bid to acquire metal 3D printing IP may come at a lower price. This could accelerate HP’s entrance into the metal space, or bring further consolidation from another company.

No doubt major multi-national printing companies yet to fully play their 3D printing hands will be watching events over the following months closely, as will 3DPI.

All images by Michael Petch