Researchers from the University of California San Diego have used 3D printing to produce soft and flexible, walking “insect-like” robots.

The budget-minded additive manufacturing technique used to create the bots could lower the cost of entry for 3D printing soft robotics, and open new applications for the technology in places that aren’t safe for humans, such as navigating disaster or war zones.

“We hope that these flexoskeletons will lead to the creation of a new class of soft, bioinspired robots,” said Nick Gravish, a mechanical engineering professor at the Jacobs School of Engineering at UC San Diego. “We want to make soft robots easier to build for researchers all over the world.”

Making 3D printing soft robotics more accessible

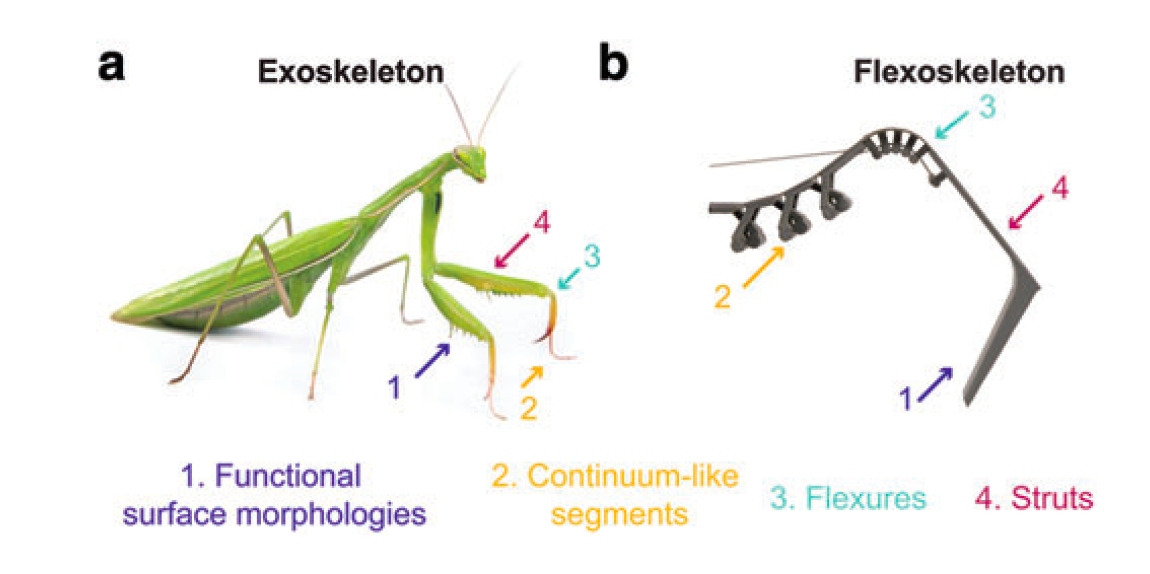

One of the main challenges of producing insect-inspiring robotics, according to the researchers, is recreating the complexity of exoskeleton structural mechanics. The outer shell needs to serve multiple roles, including structural support, joint flexibility, and body protection, while providing functional surface features for sensing, grasping, and adhesion.

What the San Diego research team observed was that insects’ limb mobility is determined by an arrangement of rigid, soft, and graded stiffness elements and the insect exoskeleton is a hybrid structure of rigid and soft mechanical parts. Future iterations would, therefore, require a hybrid approach to construction, in order to better reflect the insect models on which they’re based.

Previous attempts to create insect-inspired bots have required access to multi-material 3D printers, and multistep casting processes. Scientists from the University of Rochester for instance created water-rider-inspired jumping robotic insects in 2015. According to the San Diego researchers though, such bio-inspired robots have tended to look more like their rigid industrial robot counterparts, consisting of inflexible links and stiff, high-gear ratio motors. More recently, roboticists have begun to intentionally include body and limb compliance in robot designs, using multi-material 3D printing, laser-cutting, lamination, and mold-casting. These manufacturing techniques also have drawbacks, as they often come at the cost of accessing expensive and time-consuming fabrication tools that offer a limited material selection.

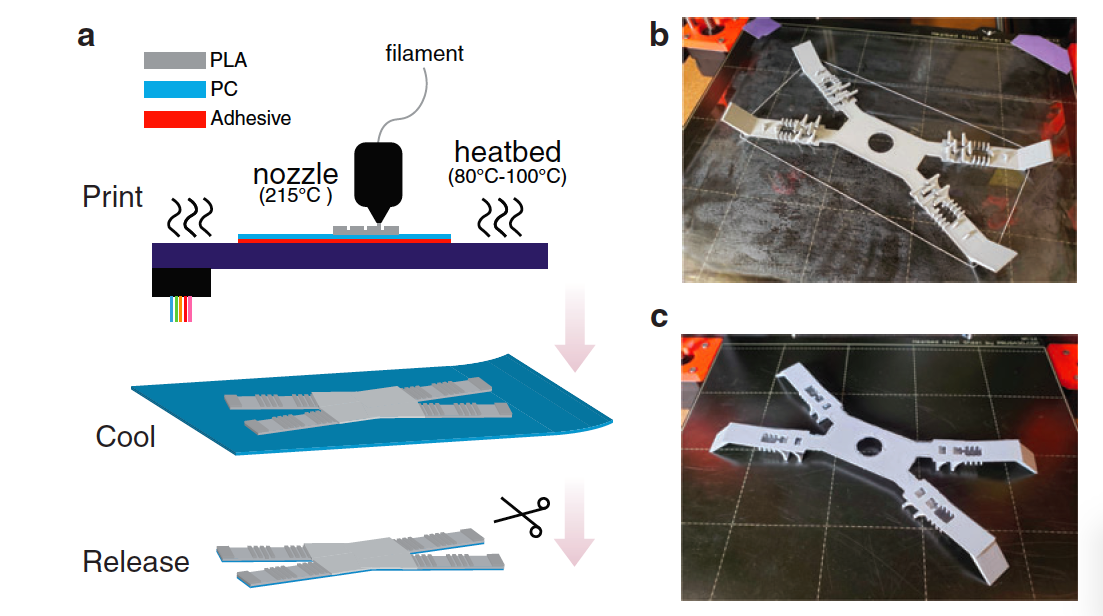

To enable them to 3D print flexible and resilient exoskeletons in a more cost-friendly way, the research team devised a novel hybrid approach called flexoskeleton printing. Using Fused Deposition Modeling (FDM) 3D printers, and standard filament materials such as acrylonitrile butadiene styrene (ABS), made the method cheaper and more accessible. Moreover, the new technique varies from traditional approaches to soft robot manufacturing, by 3D printing rigid filaments directly onto a heated thermoplastic film. This approach provides a flexible yet strong base layer to the deposited material and enables precise control over the stiffness and properties of joints and struts within the robot body.

Additive manufacturing “insect-like” soft robots

In standard FDM printing, a plastic filament such as ABS or polylactic acid (PLA) is extruded through the aperture of a heated nozzle and deposited onto a flat print surface. The flexoskeleton process, on the other hand, uses modified Prusa i3 MK3S or the LulzBot Taz 6 FDM 3D printers, to deposit filament directly onto a heated thermoplastic base layer. This results in high bond strength between the deposited material and the inextensible, flexible base, yielding improved fatigue resistance. The bonding process for flexoskeleton printing does not require additional adhesives or curing agents either, because the filament is directly bonded to the base layer during extrusion.

In order to test the strength and fatigue resistance of the components produced, the team fabricated flexible beams with uniform rectangular geometries. Each beam was bent to a constant stress state and maintained this position for 10 seconds to simulate scenarios where robot legs are bent and held in place for load support. The research team then measured the creep angle of the beam, by taking an image of the unloaded beam deflection angle, which was measured from the neutral position before testing. By adding a polycarbonate (PC) layer, the San Diego researchers found that they were able to reduce the creep deformation of 3D printed beams by 70%, over a 300 load cycle period.

To demonstrate the walking capabilities of robots produced using the flexoskeleton production method, the team built a tendon-driven four-legged walking robot. Designed and assembled using all-flexoskeleton produced limbs, the bot’s chassis was actuated by four micro servos. The individual legs, which were 70 mm in length, took 30 minutes each to 3D print and featured two joints: one flexion and one extension. Once the whole robot had been produced (taking around three hours), each limb was inserted into the robot chassis (body), and connected with one micro servo through a single tendon and capstan. The finished product featured interchangeable legs, which were designed for different terrains, and the completed bot was able to reach a speed of nearly 5cm per second during testing.

Not only was the flexoskelton robot’s outer structure able to protect its internal components, but its mixture of soft and rigid components, allowed it to be produced in a complex 3D arrangement. The innovative production technique used to create the bot could allow for the production of new multifunctional robots, for use in a factory setting, according to Gravish.

“The ultimate goal is to create an assembly line that prints whole flexoskeleton robots without any need for hand assembly. A swarm of these small robots could do as much work as one massive robot on its own-or more,” said Gravish.

Soft robotics in 3D printing

Research into the additive manufacturing of soft robotics has taken on a variety of forms in recent years. In January 2020 for instance, researchers from Cornell University developed a 3D printed soft robotic muscle that was capable of “perspiration.” Using hydrogel-based composite resins and stereolithography (SLA), soft, fingerlike actuators were produced that could retain water and respond to temperature.

In August 2019, researchers from the Delft University of Technology (TU Delft) in the Netherlands, created multi-colored 3D printed sensors to aid the self-awareness and adaptability of soft robots. By innovating a flexible, embedded 3D printed sensing method, the researchers increased the interactions between robot and object.

A pair of NASA researchers announced that they had used 3D printing to produce a soft robotic actuator in May 2019. The new component, which was responsible for animating and controlling the robot’s moving parts, represented an important step towards bringing soft robotics into space.

The researchers’ findings are detailed in their paper titled “Flexoskeleton Printing Enables Versatile Fabrication of Hybrid Soft and Rigid Robots,” published on April 7th, 2020 in the Soft Robotics journal. The research was co-authored by Mingsong Jiang, Ziyi Zhou and Nicholas Gravish.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows how the flexoskeleton robot produced by the researchers was inspired by the outer structures of insects. Image via Soft Robotics.