Researchers from the Delft University of Technology (TU Delft) in the Netherlands, have created mulitcolored 3D printed sensors to aid the self-awareness and adaptability of soft robots.

As stated by Rob Scharff, the first author of the study published in IEEE/ASME Transactions on Mechatronics, soft robots can bend, stretch and twist at the same time, making existing sensors unsuitable. With a flexible, embedded 3D printed sensing method, a large variety of deformations can be detected, increasing the interactions between a robot and object.”These are important characteristics for robots that closely interact with humans or fragile objects, for example, care robots or grippers that handle fruits and vegetables of various sizes,” comments Scharff. “As the interactions that occur here are very unpredictable, the robots need to be able to sense the position of their own fingers and body.”

3D printed soft robots

Made from highly flexible materials, soft robots are capable of natural movements similar to living organisms. Currently, NASA is using actuators from 3D printed silicone molds to build soft robots designed for space exploration. Other applications are also been investigated in medicine, and zoology.

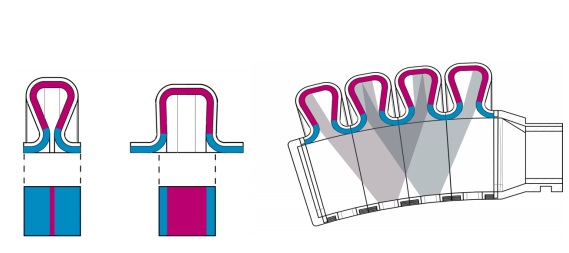

The TU Delft researchers implemented Stratasys PolyJet 3D printing and Agilus Black, VeroCyan and VeroMagenta materials to create bending actuators maintaining an air with an extensible bellow-shape at the top. According to Scharff, “Inflating the air chamber will cause the bellows at the top to expand, while the bottom remains at the same length, creating a bending motion.”

To add “sensing” capabilities, Scharff adds, “We 3D print a color pattern inside these top bellows and observe these color patterns with color sensors at the inextensible bottom of the actuator,”

“When the actuator is inflated, colors that were previously occluded from the sensors start to appear. We use this change in color and the changes in light intensity to predict the shape of the actuator.”

A firm gripper

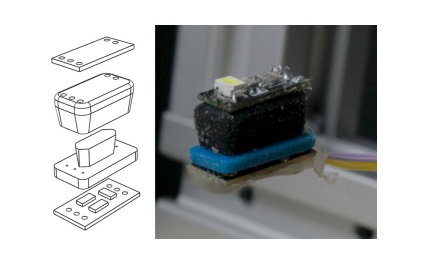

The sensors operate using a feedforward neural network (FNN). There are 1,000 samples of sensor values collected within the FNN which correspond with actuator shapes. The actuator shapes are represented by six markers on the inextensible layer that were tracked by a camera. The inputs of the network are readings from 4 color sensors with 4 channels (red, green, blue, white).

“Our method is able to predict the position of each of the markers with an error that is

typically between 0.025 and 0.075mm,” added Scharff.

“Unlike existing sensors in soft robotics, we are able to measure the exact shape of how a gripper is bent around an object. Therefore, the work is a big step towards being able to accurately move and grasp objects with soft robots.”

“Color-Based Proprioception of Soft Actuators Interacting with Objects” is co-authored by Rob Scharff, Rens Doornbusch, Zjenja Doubrovski, Jun Wu, J.M.P. Geraedts, and Charlie Wang.

For the latest additive manufacturing research, subscribe to the 3D Printing Industry Newsletter, follow us on Facebook and like us on Twitter.

Seeking 3D Printing Jobs? Join and advertise on our dedicated site now to reach professionals in this industry.

Featured image shows an illustration of the actuactor and color sensor. Image via TU Delft.