3D printer manufacturer Ultimaker has launched a beta version of its new open-source slicing software, Cura 5.0.

According to Ultimaker, the latest Cura features an enhanced engine that allows users to deploy a variable line width during slicing, and reach a “new threshold for finer and faster 3D prints.” The update also brings profile and user interface (UI) improvements among a slew of other upgrades, including greater M1 chip support, thus it should bring adopters of Apple’s newest machines a better user experience.

“We believe that even those who have looked at 3D printing before and concluded that it may not be ready for their use, today it is time for them to look again,” said Miguel Calvo, CTO of Ultimaker. “Until now, you had to make your design work for 3D printing. It’s time to turn the table… from designing for 3D printing, to 3D printing for design.”

“Ultimaker Cura 5.0 represents the biggest leap forward in print quality that the software has ever seen. This is the start of a true revolution in 3D printing technology.”

Ultimaker’s software portfolio

Since being founded in 2011, Ultimaker has built up a range of open-material Fused Filament Fabrication (FFF) 3D printers, designed to accelerate what it describes as a global shift towards “flexible, empowering and sustainable” production.

One of the ways the firm has sought to work towards this goal, is via the introduction of its own software portfolio, including its Academy, Digital Factory and Cura offerings. While the former are geared towards helping users upskill, and those with multiple systems streamline print management in addition to data gathering and part digitization, the latter is a modelling software designed for simplified slicing.

Available free of charge, as well as in the upgraded Essentials, Professional and Excellence packages, Cura is based around an open-source slicing engine. Built over years of in-house R&D and user input, the slicer provides adopters with the ability to either rapidly prepare prints via pre-configured profiles, or dive deep into its more than 400 settings in ‘custom mode,’ which offers granular process control.

Cura also offers integration with several other leading CAD programs, including SolidWorks, Siemens NX and Autodesk Inventor, and Ultimaker continues to roll-out add-ons that bring new functionality to the software, one of which has seen Teton Simulation launch SmartSlice for Cura, a plug-in that enables users to assess part performance prior to printing.

Precision slicing with Cura 5.0

Unveiled at the recent Ultimaker Showcase on April 21, 2022, the latest Cura is packed with features designed to allow users to print with greater precision, and potentially even address new applications. Chief among these additions is the software’s upgraded engine, which now allows for the use of a variable line width when slicing a part model.

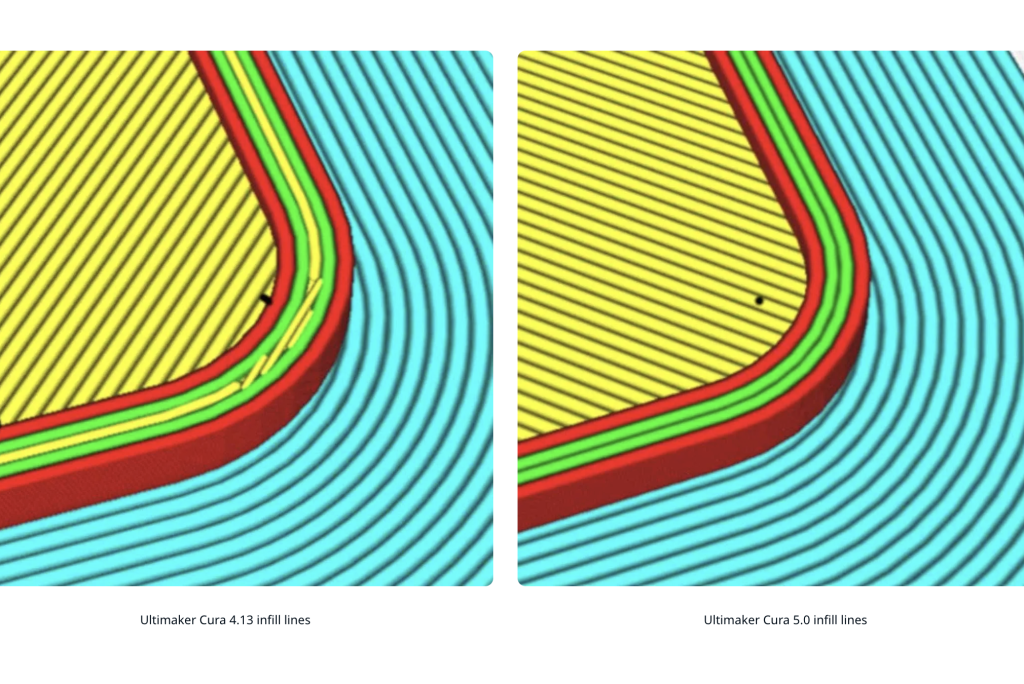

In previous Cura versions, line width was decided by the diameter of a printer’s nozzle and the settings used. Though this allowed consistent line widths to be achieved in a given build, it also meant that if a print was two-and-a-half lines thick, only two would be used, leaving a small gap between them. In the case of smaller, less than one line thick details, meanwhile, these could be unprintable.

To overcome what Ultimaker calls a “common shortfall for FFF 3D printing,” Cura 5.0 instead increases and decreases line widths to create the most efficient tool patch. In doing so, the software is said to allow adopters to create parts with fewer gaps on the inside and improve their build quality, particularly in those objects with ultra-thin walls and fine surface details.

“Fine detail and small features are critical to how architectural designers accurately communicate design decisions,” explains architectural designer and Cura 5.0 adopter Carlos Castillo. “While much can be done by hand, it’s much better for the speed of the process when you can draw on software to deliver what you need.”

“I’ve been putting the new Cura 5.0 through the paces in my recent projects, and have been surprised by the features that my 3D printers can now achieve. This is a big development for the entire architecture industry.”

By providing parts with a higher level of infill, the program also effectively makes them more solid. This improvement in strength, in the words of Ultimaker, is set to be most beneficial when printing thin walls in which a fixed line width would previously have resulted in “internal gaps,” as well as in extreme cases where “walls would not print correctly at all.”

Thanks to its new slicing engine, the program’s print profiles have received a further update as well, making them faster than ever before, and Ultimaker says that users of its machines can expect to see print time reductions of as much as 20%.

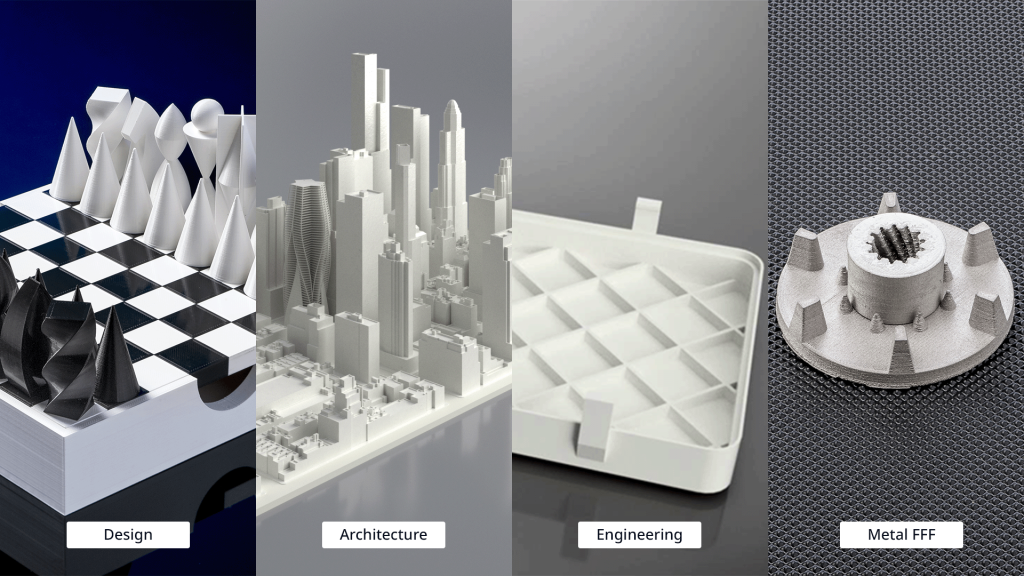

Elsewhere, Cura 5.0 features an improved UI and revamped marketplace integration, meaning that it should now be easier to find and install plugins and material profiles. Ultimaker has also managed to fix various visual bugs affecting users of Apple M1 chip machines, enabling them to join the ranks of those deploying Cura to address new design, architecture and engineering applications.

Those interested in accessing the program’s beta can download Ultimaker’s Cura 5.0 software via GitHub now.

Competing for slicing supremacy

Ultimaker is far from the only 3D printer manufacturer to have launched its own slicing program, and plenty of others have now moved to establish their own software portfolio. Raise3D has its ideaMaker slicing software, a platform built to allow users to skip lengthy CAD processing steps via ‘one-click’ parameter optimization algorithms.

Prusa, on the other hand, offers its PrusaSlicer 3D printing program, another free, open source slicing software. Previously called ‘Slic3r,’ the platform features a clear UI, custom support functionality and a rising number of material profile presets.

Away from the software created in-house by machine manufacturers, dedicated software developers have also come up with several programs designed to help users optimize their slicing workflow. One of these being Helio Additive, a Polymaker-backed start-up, which recently unveiled plans to launch an output and reliability-boosting slicer, capable of tweaking parameters to prevent print failures.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Cura 3D printing software user. Image via Ultimaker.