French software start-up Spare Parts 3D (SP3D) has entered into a joint R&D project with the French Defense Innovation Agency (DIA) and the University for Research in Automated Production (LURPA) of the École Normale Supérieure Paris-Saclay.

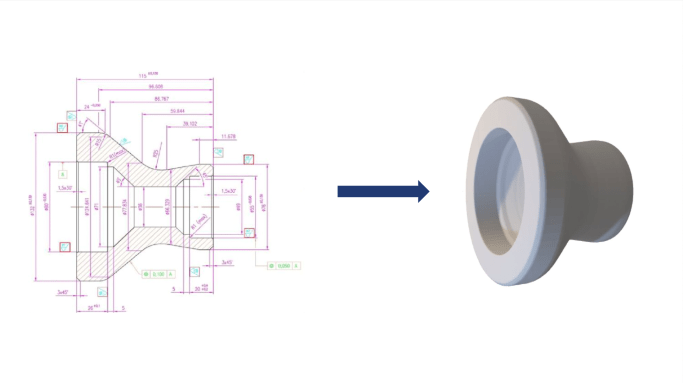

Named ‘RAPID’, the project will see SP3D’s proprietary DigiPart platform deployed to create software capable of automatically reconstructing 2D drawings into printable 3D models.

“The reconstruction of 3D models from technical drawings is a real challenge for which the combination of digital geometry processing techniques, expert and deep learning algorithms will pave the way for a considerable breakthrough in the creation of digital inventories,” said Nabil Anwer, Deputy Director of LURPA.

SP3D’s 3D printing software

SP3D provides a suite of programs designed to help customers to identify, digitize, and 3D print spare parts in a more cost-effective way. The firm has worked with a range of customers in various sectors, aiding them in reducing their storage of obsolete parts and cutting lead times for critical components.

DigiPart is the company’s flagship system and is designed to help 3D printing firms build an end-to-end digital spare parts inventory. After identifying and mapping out parts that are 3D printable, the system recommends the optimal materials and technologies with which to fabricate the components and then 3D prints the desired object.

DigiPart’s automated nature has caught the attention of various multinational clients, such as Honeywell and DNVGL, amongst others. In 2020, SP3D worked with global petrochemical firm Braskem to make its supply chain more efficient, and reduce its overall spare part spending.

Automating the reconstruction of 3D models

One of the main obstacles to the full adoption of 3D printing is the availability of 3D models of industrial equipment parts. Most such parts are represented in the form of technical drawings that must be processed by an engineer to be reconstructed as a 3D model, which can take as long as a day.

As such, SP3D calculates that if a company, like those it works with, has an inventory of 400,000 parts of which 10 percent are printable, it would take an engineer 181 years to reconstruct the models.

The R&D project with the French DIA and LURPA is seeking to automate this process by combining deep learning and computer vision techniques with existing semantic recognition of optical character recognition (OCR) capabilities. To this end, SP3D will develop an application capable of automatically reconstructing a 3D file usable for 3D printing from 2D drawings.

“The project carried out by SP3D is an essential project which will make it possible to unlock the use of 3D printing and multiple its applications in civilian life but also for the maintenance of our military equipment,” said the French DIA.

During the project, LURPA will aid SP3D with its expertise in the acquisition and geometric processing of complex shapes, reverse engineering, and 3D reconstruction.

The end goal is that, through using DigiPart, firms will be able to automatically reconstruct 3D models using only a part description and 2D drawing.

“Thanks to this program, we have set up a team at the forefront of technology for the development of this fundamental software module,” added Christophe Migliorini, SP3D’s CTO.

“This will strengthen the attractiveness of our DigiPart solution and consolidate our leadership in the identification of parts for additive manufacturing.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows through DigiPart, firms will be able to automatically reconstruct 3D models using only a part description and 2D drawing. Image via Spare Parts 3D.