Electrolux, a Swedish domestic appliance manufacturer, is performing a series of tests and analyses ahead of producing on demand 3D printed spare parts to its customers.

Electrolux is conducting the test within its Asia Pacific range together with 3D printing service bureau Spare Parts 3D. The test will comprise five stages before any 3D printing begins.

Addressing a two way problem

Electrolux is attempting to address problems affecting both the manufacturer and consumer. For the manufacturer the problem is high production, inventory and maintenance costs for spare parts after the production of the actual appliances has stopped, yet they are still in use.

For the consumer, costs of replacement increase after the product is no longer sold, and it often takes a substantial amount of time to process and ship replacement parts.

An on demand printing service

Electrolux is evaluating and trialling an on-demand 3D printing service to address both of these issues involving Spare Parts 3D and its network of affiliated 3D printing service providers.

To evaluate the benefits and feasibility of such a service, Electrolux and Spare Parts 3D are performing a five stage study.

A five stage evaluation

The first stage involves establishing the right criteria for 3D printing and choosing the best business case for Electrolux. As part of this, both printability and profitability of the spare parts on offer will be assessed.

Following this, Spare Parts 3D will conduct industrial engineering tests and reverse engineering to determine the best materials and machines for producing parts. The results of these tests are expected to be digitally catalogued.

After tests prints of spare parts are made, quality checks will be performed. The final stage will see a profitability analysis of 3D printing spare parts against traditional production methods.

Part projections

Electrolux’s 3D printing initiative comes as the company makes an move towards smart factories for the production of its electrical goods.

Across the industry as a whole, a report from January 2017 by consultancy PWC stated that for 85 percent of the spare parts providers surveyed, 3D printing would play a “dominant role” in production within the next five years. Ten percent of the same sample acknowledged current use of 3D printing in spare parts production.

Deutsche Bahn is also investigating the use of 3D printing for spare part production, for both internal maintenance and for sale to their customers.

For more information about 3D printing in manufacturing and part production, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

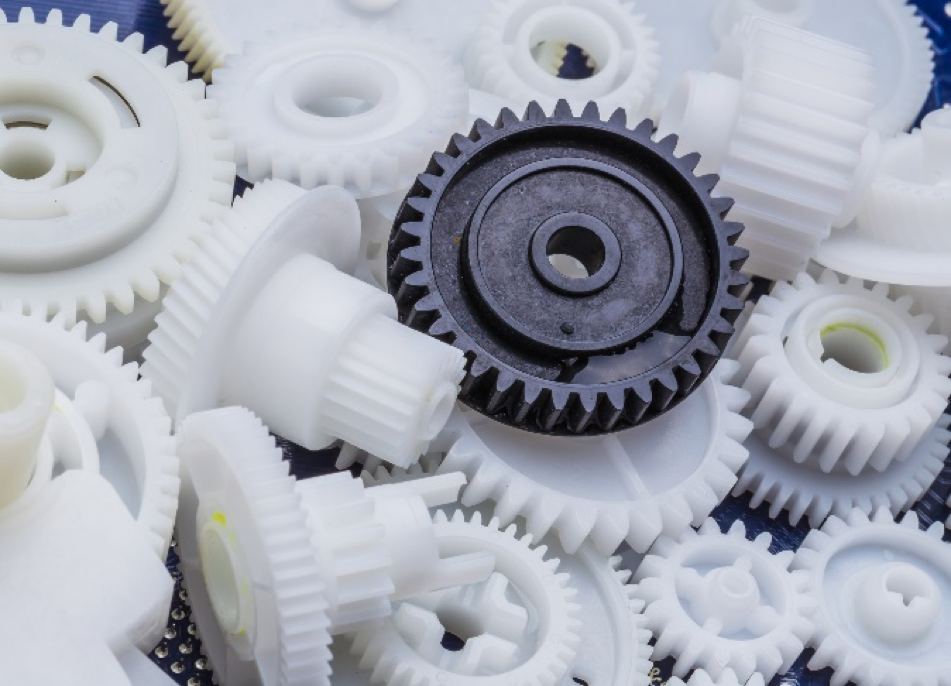

Featured image shows FFF printed spare parts on a print bed. Photo via Spare Parts 3D.