Chinese software start-up Helio Additive has unveiled plans to launch a new program that’s designed to help makers everywhere ramp up their part throughput and consistency.

Helio Additive’s software revolves around a physics-based AI engine, which adapts the way parts vulnerable to warping are sliced, so that they’re less likely to develop the type of nonconformities during printing that make them unfit for purpose.

In doing so, the firm says that its technology enables users to better avoid print failures, achieve an up to ten times greater cost-per-part ratio, and ultimately to “supercharge” their entire 3D printing workflow.

“In the last five years, hardware in 3D printing has outpaced the growth of software capabilities, leaving a bottleneck for companies ready to adopt additive [manufacturing] in their workflow,” said Helio Additive CEO David Hartmann. “At Helio, our aim is to diminish the void between software and hardware and ultimately increase the output and reliability of 3D printed parts in production.”

Helio Additive’s novel AI engine

According to Helio Additive, an average of one in six 3D prints fails and the technology has a ‘scrap rate’ of over 80%, thus it has costs that are “far too high” compared to those of mainstream manufacturing. What’s more, additive manufacturing adopters intending to use the technology for serial production applications often need quality guarantees, something the firm says are currently lacking in the sector.

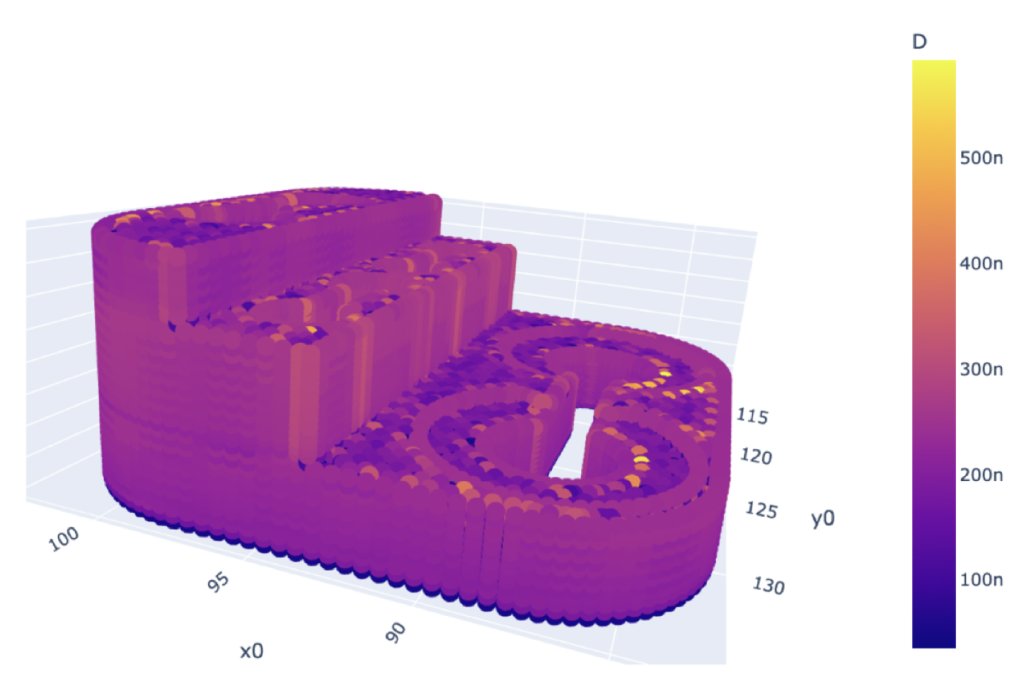

In an effort to help such manufacturers achieve greater certainty, the company has therefore developed a new AI engine, capable of breaking down 3D models into single voxels. Once it has done so, the software charts the stress relaxation and thermal history of each of these voxels, before using the resulting data to adapt the way parts are sliced, so that they avoid failures caused by heat changes during printing.

“The new generation of printers and materials have extremely powerful performance envelopes, but are printing at roughly one fifth of their maximum speed,” explains Helio Additive. “At the same time, engineers struggle with repeatability and prints fail up to five times, before getting a print right. Helio’s physics-based software uses machine learning and physics simulation to improve repeatability of printed parts by linking the printing process with required outcomes.”

Although Helio Additive acknowledges that the way a system’s hot-end affects prints as it passes over them can be different, with polymers like PLA not suffering so much from temperature change, it highlights how the higher thermal coefficient of materials like PC and PA sometimes causes them to encounter quality issues when subjected to short bursts of heat.

Utilizing its platform, the company believes that users not only stand to improve the layer adhesion and geometric compliance of these parts, but provide their machines with a process-optimizing ‘brain.’ In fact, while the firm remains in the early stages of rolling the software out, it anticipates that in future, this ‘brain’ could even be used to help more new adopters enter serial production.

Expanding into the 3D printing industry

Since it was established in the city of Changshu in 2020, Helio Additive has set out on a journey to build out its core technology and deploy it within manufacturing settings. In that time, the firm has assembled a team with a strong mixture of academic and sector expertise, including ex-Covestro man David Hartmann, and its CTOs Zhenqing Li and Priyesh Patel, who hail from Ohio State and UCL respectively.

Currently a team of just ten, Helio Additive is now beginning to scale its commercial and technology teams, and is said to be actively recruiting engineers, data scientists and programmers in both Changshu and Shanghai to aid its ongoing expansion.

Another way the company is seeking to gain traction in the 3D printing sector is via industry partnerships, and it recently announced such a collaboration with Amesos as well as one of its investors, Polymaker. Working alongside the two companies, Helio Additive is set to help them hone a new high-speed 3D printing approach they announced earlier this year.

Based around Amesos’ Blade 1 system and a custom Polymaker material, the firms say that their ‘FFF 2.0’ methodology will address a number of the drawbacks associated with regular FFF 3D printing, particularly those surrounding throughput.

Aside from the R&D work it’s conducting as part of the project, Helio Additive is also working on a standalone version of its software, which it intends to bring to market. As of yet, there’s no confirmed date for the platform’s alpha release, but it’s expected to be launched at some point later this year, and the firm’s actively looking for partners to test its capabilities.

Those interested in finding out more about Helio Additive’s physics-based AI engine can do so via its website.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the home page of Helio Additive’s software. Image via Helio Additive.