Metal and carbon fiber 3D printer manufacturer Markforged has announced the acquisition of engineering software developer Teton Simulation.

Teton Simulation is best known for developing SmartSlice, a program that enables users to automatically validate and optimize the performance of parts based on the needs of specific use cases. Having now bought the firm, Markforged says that it plans to integrate the software into its Eiger platform, as a means of allowing for the rapid validation of prints in “even the most demanding applications.”

“Teton’s integration and fit with Markforged’s tech stack provides the perfect home to develop the next level of additive manufacturing solutions,” said Brady Adams, CTO of Teton Simulation. “So many elements of the Digital Forge, including Continuous Fiber Reinforcement (CFR), are game changers, and I am so excited to get an opportunity to integrate our advanced simulation technology to help manufacturers all over the world take additive [manufacturing] to the next level.”

Markforged’s software offering

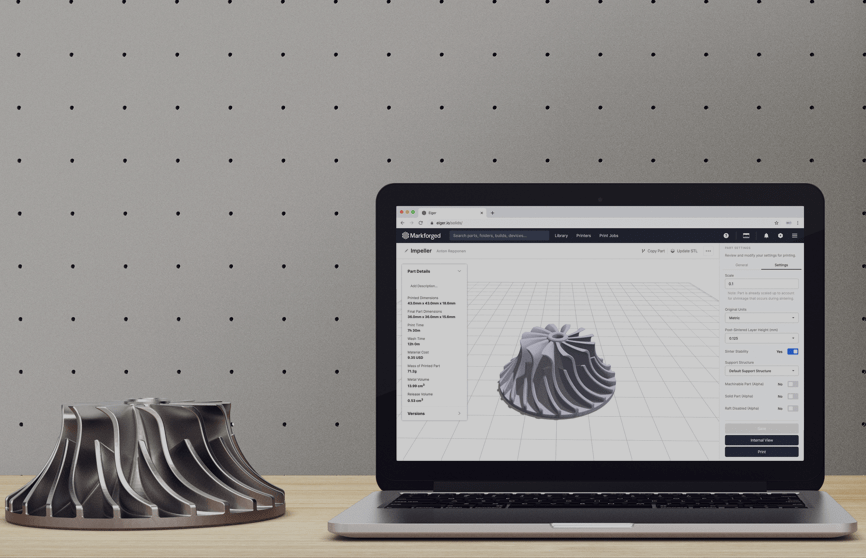

Markforged may have built a reputation on its ability to deliver machines capable of printing robust metal parts, as well as those reinforced by materials like carbon fiber, fiberglass and kevlar, but in order to really get the very best out of these systems, it has also established its own proprietary software range.

The first of the firm’s current programs to launch was Eiger, which came out in 2014 with its original Mark One 3D printer. Designed to allow users to get from CAD model to functional part as quickly as possible, the browser-based software includes all the features needed to create builds, print parts and monitor their progress within a seamless workflow.

Over the last eight years, Markforged has also sought to build on the industrial-scale production potential of its portfolio, and launched the Digital Forge in late-2020 with this goal in mind. The platform encompasses the firm’s material, system and software offering, but brings a particularly significant update to the latter, in that it harnesses machine learning to make each print better than the last.

Since then, Markforged has released Blacksmith, an AI-powered platform that connects part design, production and inspection to help users cut waste and accelerate their product’s time to market. In practice, when used with the firm’s X7 3D printer, the program measures the accuracy of parts as they are being printed, and it’s said that this data can also be used to improve print accuracy over time.

In addition to expanding its software portfolio, Markforged has continued to upgrade Eiger’s capabilities as well, releasing Eiger Fleet in September 2021. Built from the ground up to help users scale existing workflows, the program essentially allows manufacturers to remotely drive efficiency from Markforged machines, and create a ‘distributed manufacturing fleet’ while retaining a high level of part quality.

Teton Simulation’s SmartSlice add-on

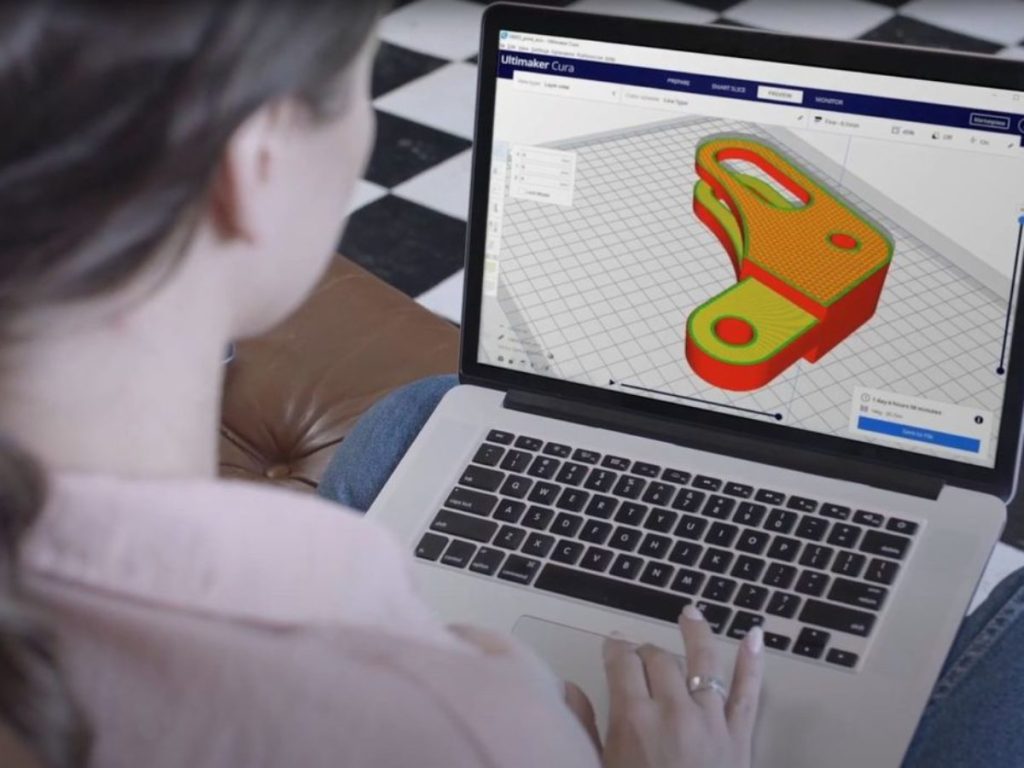

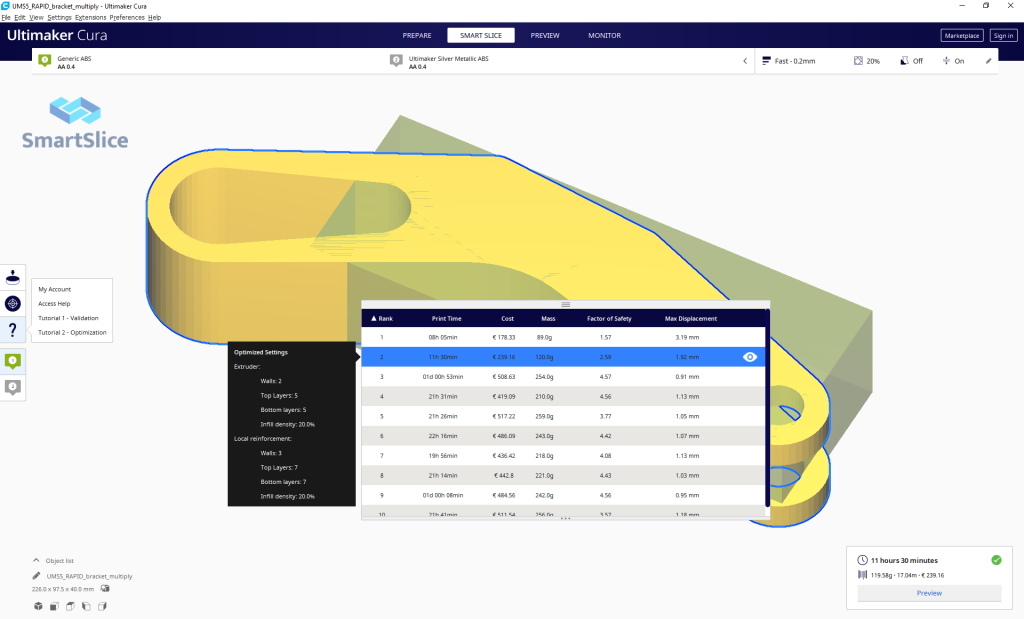

Teton Simulation flagship SmartSlice software, meanwhile, is designed for integration into other slicing programs, after which it helps users accelerate the process of part parameter optimization. By cutting out the lengthy simulations or build-break cycles often required to establish the ideal printing setup, the program effectively allows adopters to drastically reduce their part waste and lead times.

In the past, the technology has been added to Ultimaker’s Essentials platform and Stratasys’ GrabCAD Software Partner Program, as a means of enabling users of both firms’ machines to fully-optimize their builds. SmartSlice has also been deployed in larger-format applications as part of a Teton Simulation and BigRep partnership, which has seen it used to enhance the efficacy of 3D printing at scale.

Following its acquisition of Teton Simulation, Markforged itself now plans to offer the software as a subscription add-on to Eiger users, which expands the platform so that it allows for design, testing, optimization, validation and printing, all in one place. According to the firm, this new offering will give users more confidence that “printed parts will perform as intended,” and potentially create further use cases for its technologies.

“The acquisition of Teton Simulation advances our industry leadership in using software to increase process automation and offers our customers an easy way to validate their parts on the same platform they use to print them,” explained Shai Terem, CEO of Markforged. “Adding this functionality enables our customers to utilize the Digital Forge deeper into their manufacturing operations.”

Additionally, as part of the deal, Teton Simulation’s team will join Markforged’s software organization to help expand the number of industrial problems its Digital Forge solves. For Teto Simulation’s part, its CEO Doug Kenik says the agreement could not only allow SmartSlice to reach a wider audience, but via its integration into Eiger, also help drive the adoption of 3D printing more broadly.

“Our team believes in the potential of additive technologies to truly change how we manufacture things, and have worked tenaciously to design a software offering that enables broader adoption of additive,” added Kenik. “Joining Markforged integrates our technology into a state-of-the-art solution that will reach a broader customer base, and offer resources to scale it.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an engineer using Teton Simulation’s SmartSlice software. Image via Teton Simulation.