Singapore 3D printing service bureau Spare Parts 3D has joined a DNV GL Joint Industry Project (JIP) for additive manufacturing.

Together, Spare Parts 3D and the global quality assurance and risk assessment company will work on standard procedure for integrating 3D printing within marine, offshore, oil and gas industries.

“We see a fantastic opportunity in collaborating with DNV GL on this JIP to communalize and frontload the qualification & certification efforts and to build a Marine and O&G industry standard,” comments Paul Guillaumot, CEO of Spare Parts 3D.

“Qualification of AM parts is not a work that you can start when your equipment is down,”

“Our ambition for this collaboration is to finally deliver the promised value of Additive Manufacturing for Marine and O&G on-demand spares produced locally to cover shortages.”

Additive manufacturing standards – full steam ahead

For industry-wide adoption, additive manufacturing is in need of engineering-grade standardization and safety guidelines. Recently, Global standards development organization ASTM International published a guideline for powder bed fusion 3D printers, and subsequently launched its Additive Manufacturing Center of Excellence to introduce more standards to the industry.

Harnessing its industry-specific expertise, DNV GL published its first classification guideline for additive manufacturing (AM) in the maritime and oil & gas industries in December 2017. Following this, the company inaugurated its Global Additive Manufacturing Centre of Excellence within Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC), and has since launched the 3D printing approval of manufacturer (AoM) program.

Spare Part 3D digital inventory

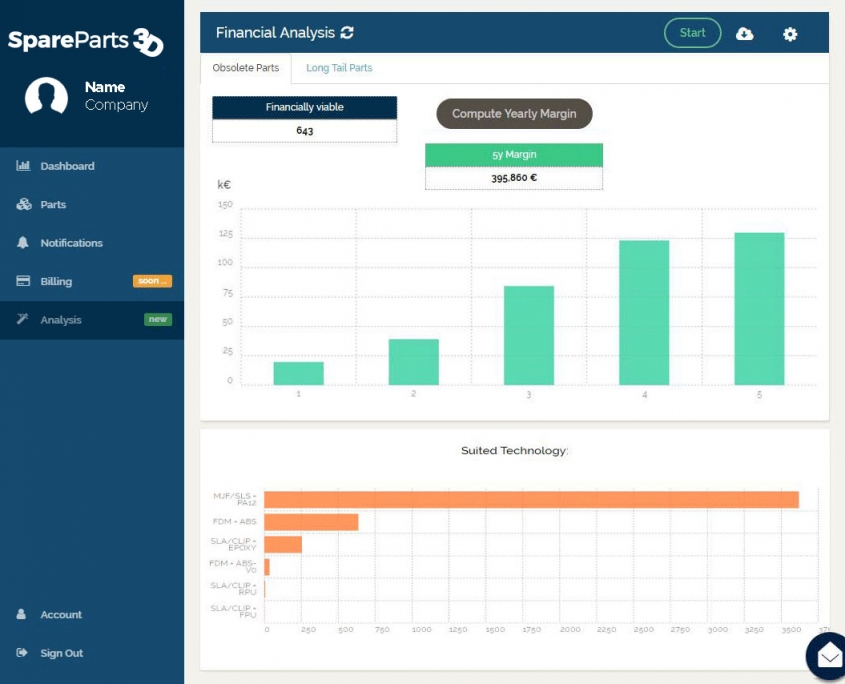

In addition to on demand 3D printing, consultancy, engineering and qualification services, Spare Parts 3D helps customers launch a digital inventory of their components. The inventory service is offered by Spare Parts 3D in the DigiPART product, a software interface providing component Printability Prediction, Financial Analysis and in process tracking of 3D printed parts. Spare Parts 3D will apply this expertise to the collaboration with DNV GL.

Overall, the aim of this JIP is to connect multiple partners from all parts of the value chain to create thorough standardized requirements for maritime 3D printing. Brice Le Gallo, Regional Manager South East Asia & Australia at DNV GL, comments, “A lot of companies we are working with are curious about AM and indicating they are considering implementing additive manufacturing into their business in the future but sometimes lack the skills and knowledge to adopt this technology,”

“I am very glad that Spare Parts 3D is partnering us in our JIP as they support companies to foster the use of AM into their business at a large scale and bring a strong expertise in supply chain management.”

Additive manufacturing in maritime

A relative latecomer to the 3D printing industry, the maritime sector has recently experienced a rise in the number of additive manufacturing applications and initiatives.

In November 2016 RAMLAB, a facility dedicated to using wire arc additive manufacturing (WAAM) for shipbuilding, made its home in Rotterdam’s RDM Innovation Dock. And global marine and offshore engineering group Sembcorp Marine has added additive manufacturing to its future plans.

Advanced and additive manufacturing service bureau Ivaldi Group, that helped form DNV GL’s maritime guidelines, recently launched an on-demand parts production partnership with Wilhelmsen the largest maritime network in the world.

Subscribe to the 3D Printing Industry newsletter, and join us on Facebook and Twitter for all the latest developments in additive manufacturing standardization.

Find your next career move or find new skilled additive specialists with 3D printing jobs.

Featured image shows surveyors on a shipbuilding project. Photo via DNV GL