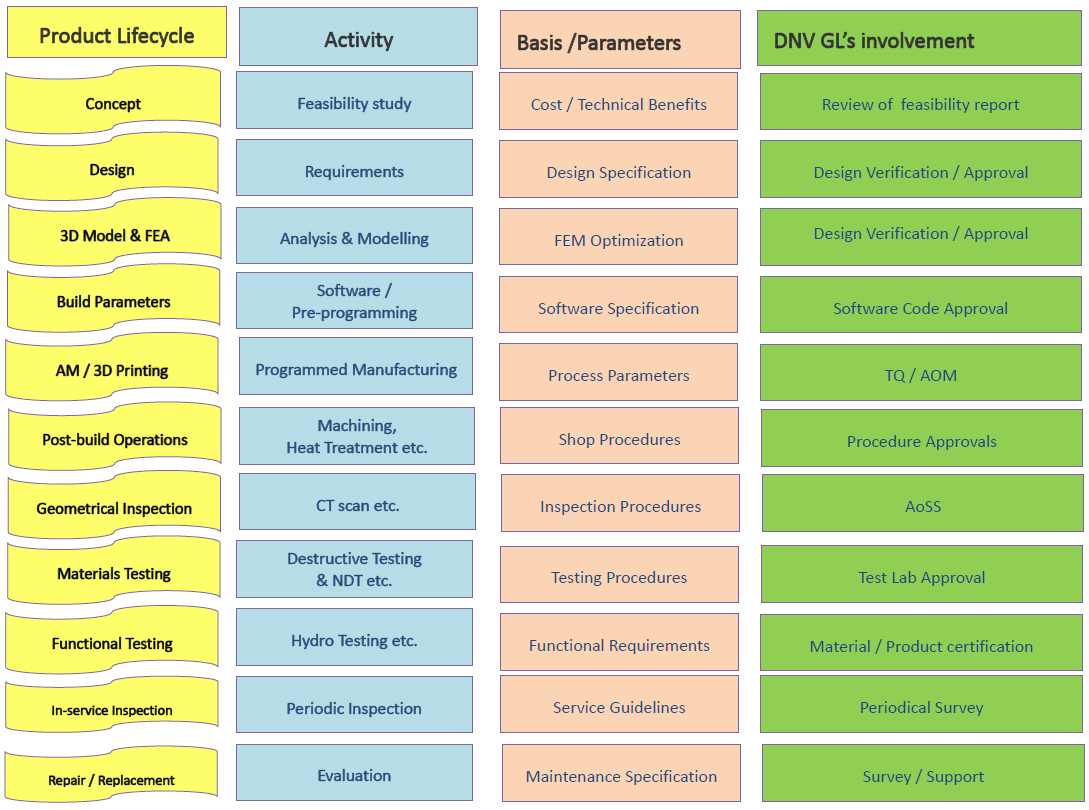

International classification society DNV GL, who recently published its first classification guideline for additive manufacturing in the maritime and oil & gas industries, has released a class approval of manufacturer (AoM) program for 3D printing manufacturers.

Also the first of its kind, the AoM program, in accordance with the DNV GL rule requirements, will validate a manufacturers’ ability to consistently produce materials and products to given specifications.

“Additive manufacturing is a technology that holds a great deal of promise for the maritime industry,” said Knut Ørbeck-Nilssen, CEO of DNV GL – Maritime.

“Our responsibility is to give manufacturers a clear path they can take to offer their innovative products, while ensuring that our customers can have the same confidence in an AM product as they do in any other that has undergone approval by class.”

Enabling 3D printing in the maritime sector

As a global quality assurance and risk management authority DNV GL is heavily invested in the development of standards for additive manufacturing. Its 48-page guideline for 3D printing in the maritime and oil & gas industries was published to assess all aspects of the process, i.e., materials manufacturing procedure qualification, data transfer, 3D printing, and post-processing. In addition, the company recently established the Global Additive Manufacturing Centre of Excellence in Singapore which is designed to develop qualification, certification, and training for 3D printing.

With the new AoM program DNV GL expands on the standards set by the industry, and is requesting that manufacturers wishing to supply products to advanced sectors must undertake a proof of concept before applying the technology to an order.

“The release of the AoM programme opens up new opportunities for both producers and users of these products, creating potential efficiencies in logistics and supplies chains, as well as in on-board maintenance and repair,” explained Ørbeck-Nilssen.

“Above all, however, we must ensure that safety and quality standards are upheld, and this new programme allows producers to demonstrate their fitness to the shipping industry.”

3D printing propels maritime transportation

Additive manufacturing is proving to be a promising method in the maritime sector to efficiently produce industrial replacement components. Last month, large-scale metal 3D printing bureau AML Technologies’ facility specializing in wire-arc additive manufacturing (WAAM) received accreditation additive manufacturing facility qualification from Lloyd’s Register (LR). WAAM has produced a 3D printed ship propeller for RAMLAB as well as a 3D printed tugboat propeller for the Damen Shipyards Group.

Additionally, Ivaldi Group, a contributor to DNV GL’s martime guideline, recently exited stealth mode in an on-demand 3D printing agreement with Wilhelmsen, the largest maritime network in the world.

For more of the latest 3D printing news sign up to the 3D Printing Industry newsletter, Also, follow us on Twitter, and like us on Facebook.

Searching for new talent or seeking a career change? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

Featured image shows a 3D printed aluminum replica of mooring chain testing bed at the DNV GL’s lab in Bergen. Image via DNV GL.