Singapore’s National Additive Manufacturing Innovation Cluster (NAMIC) has received a boost with the launch of a new research center and the construction of a nanofabrication facility for multi-disciplinary research.

Global quality assurance and risk management company DNV GL has established a Global Additive Manufacturing Centre of Excellence in the cluster.

Furthermore, a new nanofabrication facility under construction at the National University of Singapore (NUS) will involve the use of 3D printing and packaging for the prototyping of new technologies.

Quality Control at DNV GL’s Centre of Excellence

According to DNV GL, there has been a relatively low uptake of 3D printing within the offshore & marine (O&M) sector owing to the challenges of challenges in qualification and certification.

To address this, DNV GL aims to provide the industry with technical standards and guidelines for qualifying and certifying AM equipment, processes, products, materials and personnel.

The company has already teamed up with Australia’s Aurora Labs to develop a certification framework for 3D printed metal parts. Following three years of investigation into 3D printing processes, DNV GL published its first classification guideline for additive manufacturing in the maritime, oil and gas industries in November 2017.

The next step is a joint industry project (JIP) to define clear requirements for 3D printed parts, which DNV GL is undertaking with key stakeholders to develop guidelines enabling the safe introduction of additive manufacturing to O&M industries.

Research & Development at DNV GL’s Centre of Excellence

The new center will primarily serve as an incubator and testbed for R&D on 3D printing in O&M. It is supported by the Singapore Economic Development Board (EDB), and will develop qualification, certification, and training for 3D printing.

Research has already begun in collaboration with Sembcorp Marine, SIMTech and other NAMIC members to develop and certify laser aided additive manufacturing (LAAM) technology.

SIMTech’s LAAM technology is currently being applied to the fabrication of large-scale structures for new shipping vessels and component repair DNV GL CEO Remi Eriksen said:

“With our long track record in R&D and strong position in developing industry technical standards, DNV GL’s Global Additive Manufacturing Centre of Excellence will play a catalytic role in the oil & gas, offshore and marine sector.”

Supporting the investment in Singapore, Singapore EDB’s assistant Managing Director Lim Kok Kiang added, “DNV GL’s Global Additive Manufacturing Centre of Excellence (CoE) will help enhance the manufacturing competitiveness of Singapore’s marine and offshore engineering industry.”

NUS 3D nanoprinting

NUS’s new nanofabrication facility will serve as a research platform for collaboration between multi-disciplinary research groups within the university, as well as industry partners.

It will host the Hybrid-Integrated Flexible Electronic Systems (HiFES) programme, which aims to develop next-generation hybrid flexible electronics and has recently secured S $4.9 (US $3.7) million of partnerships with industrial partners.

Prototyping of new technologies at the facility will involve precision 3D printing, a combination of semiconductor and additive-based processes.

Such technologies include nanomaterial-based reconfigurable interconnects which can introduce artificial intelligence to flexible electronics, hence enabling machine learning for new wearable medical devices and sensors.

“This world-class facility, when fully operational, will accelerate the development of disruptive, cutting-edge applications in hybrid flexible electronics,” said Professor Aaron Thean, Director of HiFES. “We are keen to collaborate with more companies to bring novel technologies to market.”

Tell us what you think the best 3D printing application was this year. Make your nominations for the 3D Printing Industry Awards 2018 now.

For more stories on 3D printing in marine R&D, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

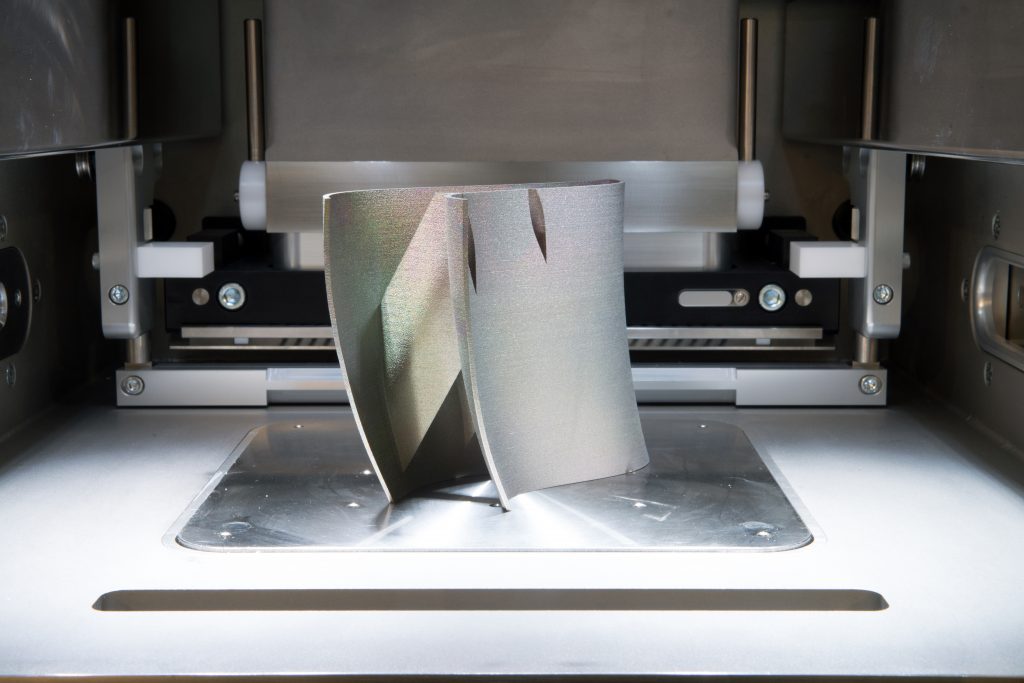

A 3D-printed aluminum replica of mooring chain testing bed at the DNV GL’s lab in Bergen. Image via DNV GL.