Researchers from the University of Sheffield and Imperial College London (ICL) are exploring crystallographic microstructures in metallic alloys to improve the durability of 3D printed parts.

As a result of this research, the team has developed ‘meta-crystals’ that incorporate novel lattice compositions, mimicking the structure of a single crystal – a material in which the composition is continuous and unbroken, with no grain boundaries.

“This approach to materials development has potentially far-reaching implications for the additive manufacturing sector,” said Professor Iain Todd, from the Department of Materials Science and Engineering at the University of Sheffield.

“The fusion of physical metallurgy with architected meta-materials will allow engineers to create damage-tolerant architected materials with desired strength and toughness, while also improving the performance of architected materials in response to external loads.”

3D printed meta-crystals

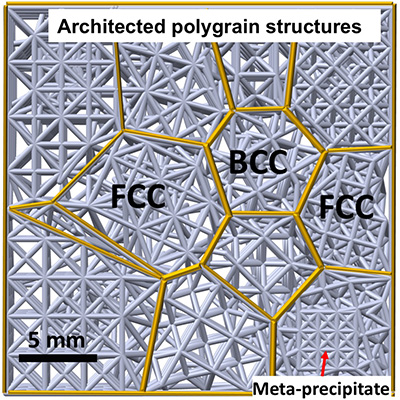

Lattice structures are frequently utilized within 3D printed materials as an infill pattern, making components lighter, stronger, and more flexible. According to the researchers, such structures replicate the structure of a metallic single crystal as it maintains a uniform layout with nodes all conforming to a regular array.

Despite its ability to withstand deformation at extreme temperatures, single crystal materials are said to have limitations relating to their mechanical performance. For example, then the structure is compressed, the lattice can split from one or more of the planes of nodes, causing permanent deformation.

“In polycrystalline materials – those with many crystals – the alignment of the atomic planes is random, so when a shear force is in a particular direction, a crack will slow down or stop when it meets a crystal,” the study states.

Thus, the researchers began to mimic polycrystalline microstructures in 3D printed lattices with the aim of developing robust, damage-tolerant materials.

Advances in multi-material 3D printing

By computer modeling atomic structures, the team intends to change the way materials are designed. Following experimental testing of components made from their meta-crystals, the researchers found that the 3D printed parts were highly energy absorbent.

The polycrystal-like material was able to withstand around seven times the energy before failure when compared to the materials mimicking the single-crystal structure.

Dr Minh-Son Pham, Assistant Professor in the Department of Materials, ICL, explained, “This meta-crystal approach could be combined with recent advances in multi-meta-material 3D printing to open up a new frontier of research in developing new advanced materials that are lightweight and mechanically robust, with the potential to advance future low carbon technologies.”

The research paper entitled, “Damage-tolerant architected materials inspired by crystal microstructure” is co-authored by Minh-Son Pham, Chen Liu, Iain Todd, and Jedsada Lertthanasarn.

Who has made the most significant academic contribution to additive manufacturing?Nominate for the upcoming 3D Printing Industry Awards 2019.

For the latest 3D printing research, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

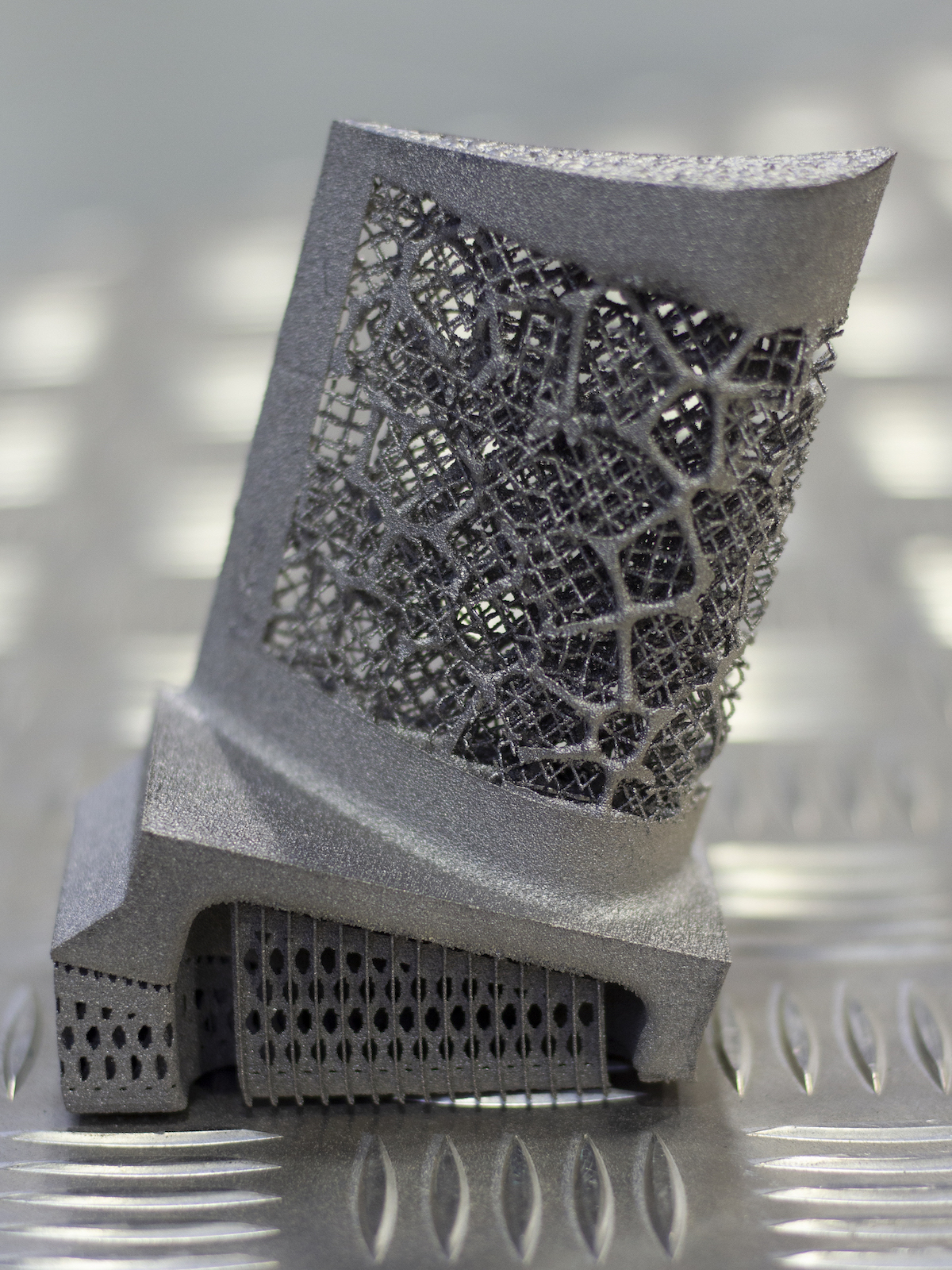

Featured image shows an artifact with varying orientations of mesostructures. Photo via the University of Sheffield.