While it may not be as a catchy as the famous song from Gentlemen Prefer Blondes, research from RMIT University argues that diamonds are (also) a 3D printer’s best friend.

More specifically, diamond, as it is made from carbon, improves the biocompatibility of 3D printed titanium implants. The breakthrough discovery made by Dr. Kate Fox and her team at RMIT’s School of Engineering sidesteps the immune system’s incredibly powerful defense mechanism which is the main obstacle to developing new treatments for the body.

“Currently the gold standard for medical implants is titanium but too often titanium implants don’t interact with our bodies the way we need them to,” explains Fox.

“To work around this, we have used diamond on 3D scaffolds to create a surface coating that adheres better to cells commonly found in mammals.”

But wait, aren’t diamonds expensive?

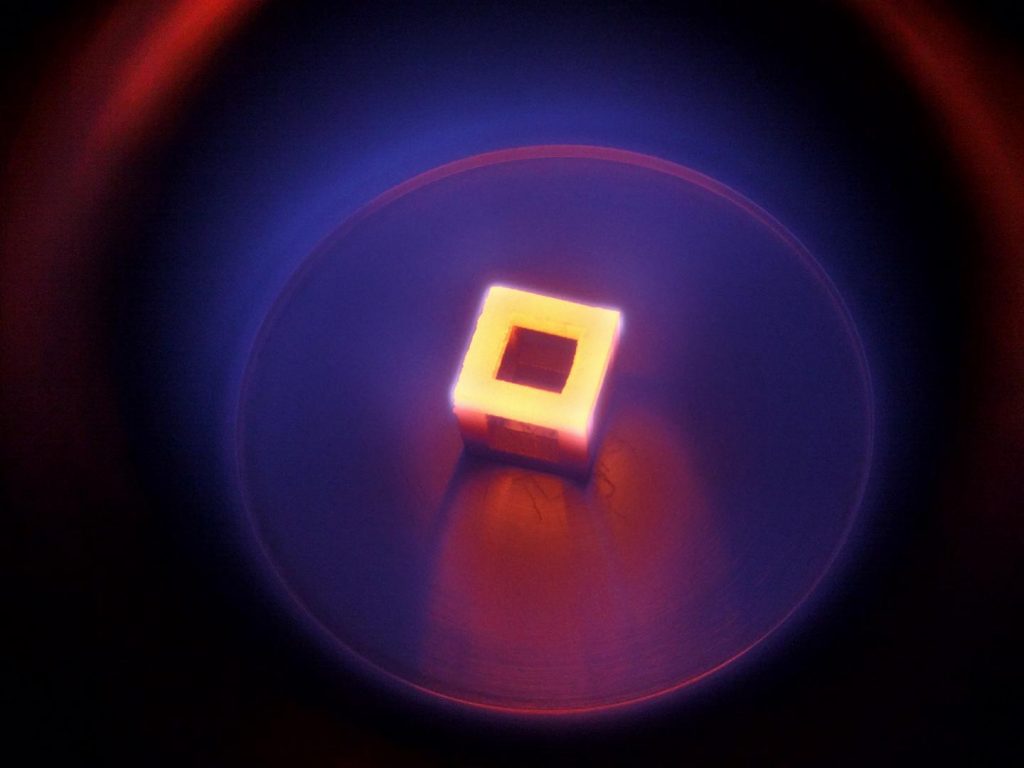

The experimental implant in the RMIT study takes the form of a hollow cube. It was 3D printed in titanium using selective laser melting (SLM). After printing, the implant was then coated in diamond by a chemical vapor deposition method, that requires temperatures in excess of 1000°C.

For the diamond coating, researchers use detonation nanodiamonds (DNDs). Synthetically made, DNDs originate in an explosive mixture of TNT and RDX. According to Fox DNDs “are cheaper than the titanium powder” used to 3D print the implants.

The body “thrives off diamond”

Seeded with mammalian cells and maintained in conditions to mimic bioactivity of fluid in the body, the diamond coated cube was compared to an un-coated titanium implant.

“This coating not only promotes better cellular attachment to the underlying diamond-titanium layer, but encouraged the proliferation of mammalian cells,” says Fox.

“The diamond enhances the integration between the living bone and the artificial implant, and reduces bacterial attachment over an extended period of time.”

The specimens were studied over a period of 2 weeks, within which the coating showed increased deposit levels of apatite bone mineral.

PhD researcher Aaqil Rifai, part of Fox’s team at RMIT, remarks, “Carbon,” the source material of diamond, “has an incredible level of biocompatibility,”

“Our body readily accepts and thrives off diamond as a platform for complex material interfacing.”

Coming soon?

RMIT is one of the recipients of AUD $12.1 million ($9.29 million USD) government funding to apply 3D printing, robotics and advanced manufacturing to the fabrication of ‘Just in time implants’. While diamond encrusted plates and pins may not yet be on the cards, Fox’s lab hopes to one day introduce the technology to commercially available implants.

“Not only could our diamond coating lead to better biocompatibility for 3D-printed implants,” comments Fox, “but it could also improve their wear and resistance. It’s an exceptional biomaterial.”

Rifai adds, “The scalability of 3D printing is growing rapidly, so we can expect to see diamond coatings to become common in orthopaedics sometime in the near future.”

The supporting paper reporting this discovery, “Polycrystalline Diamond Coating of Additively Manufactured Titanium for Biomedical Applications“, is published in ACS Applied Materials & Interfaces journal.

The study is attributed to Aaqil Rifai, Nhiem Tran, Desmond W. Lau, Aaron Elbourne, Hualin Zhan, Alastair D. Stacey, Edwin L. H. Mayes, Avik Sarker, Elena P. Ivanova, Russell J. Crawford, Phong A. Tran, Brant C. Gibson, Andrew D. Greentree, Elena Pirogova, and Kate Fox.

Never miss out on breakthrough research – subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Find and post 3D printing jobs here.

Vote for research team of the year and more in the 2018 3D Printing Industry Awards. To be in with a chance of attending this year’s event, winning a 3D printer, and having your design 3D printed by Protolabs, enter the 3D Printing Industry Awards trophy design competition.

Featured image shows a diamond gem. Photo via Pixabay