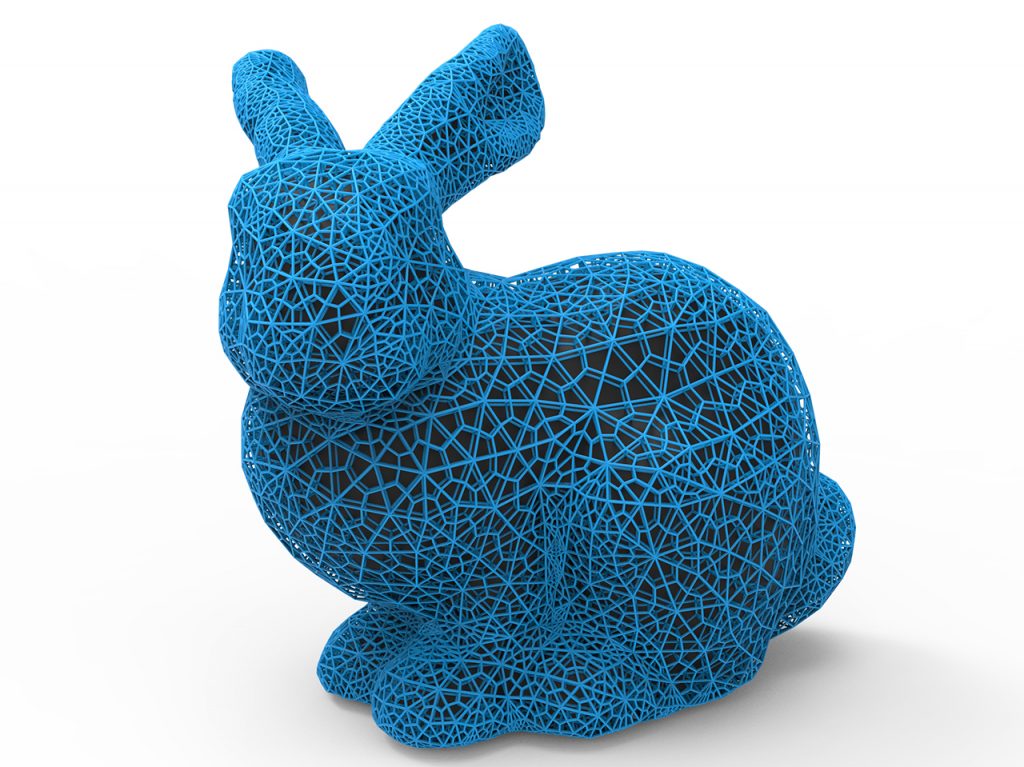

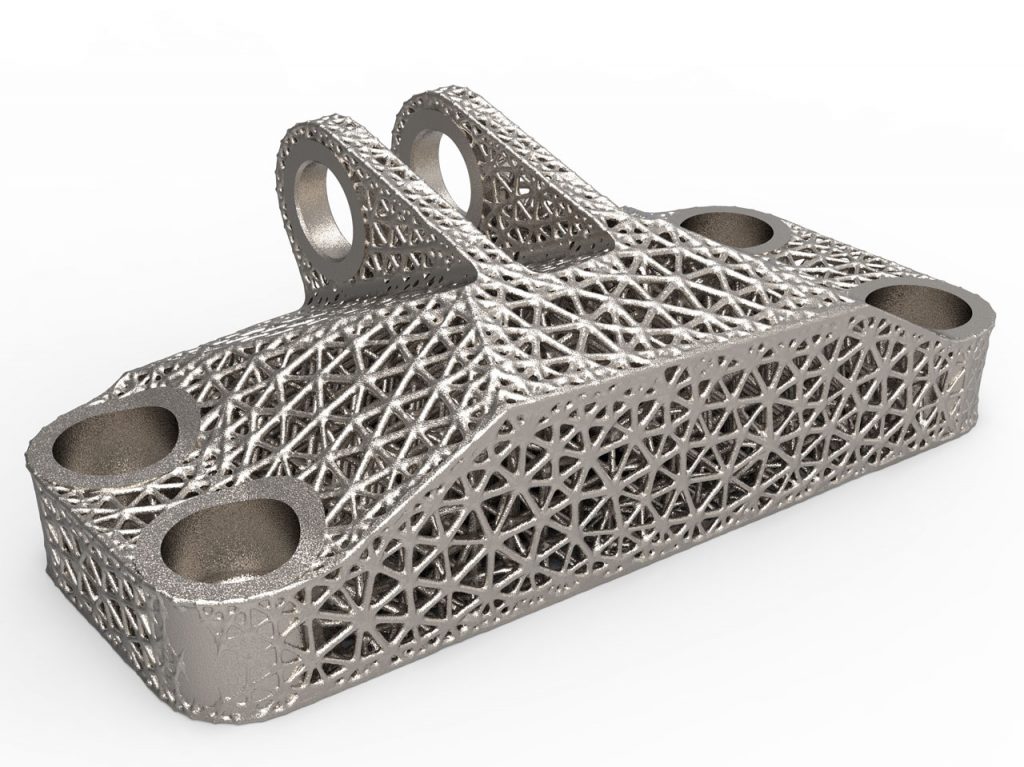

Lattice structures are integral to 3D printed designs, and Aaron Porterfield, an industrial designer at additive manufacturing service bureau FATHOM, has developed Crystallon, an open source project for shaping them into structures.

Working as a plugin extension for Rhino and Grasshopper3D modeling programs, Crystallon serves as an alternative to commercially available lattice design software, and its open source status means that it will be continually developed by its user community.

The development of Crystallon

FATHOM, co-founded by Rich Stump, and also a contributor to 3D Printing Industry’s Future of 3D Printing series, was originally approached by customers who had an interest in the application of lattices.

Crystallon began as a set of bespoke tools that Porterfield developed to address these customer challenges using his background in computational geometry and parametric design.

FATHOM decided to publicly release the tools at the end of 2017, so that the developer community could continually improve them according to their own design requirements.

The published collection of these tools, Crystallon, generates lattice structures using Grasshopper3D parametric modeling software, within the CAD program Rhino.

Both programs have been previously used together to generate complex structures by designers such as Arthur Mamou-Mani, and are advantageous since there is no need to export models to 3rd party software.

Lattices, the possibilities are endless

Speaking to the FATHOM blog, Porterfield explained that his interest in lattice structures initially began after gaining access to 3D printers machines capable of producing them.

“Lattice structures are interesting because there is almost an infinite amount of application types that would benefit from it. The most common and obvious application is structural light-weighting, but they can also be used for energy absorption, insulation, heat transfer, filtration, and medical applications.”

Porterfield went on to explain that while mainly limited to 3D printing, lattice structures provided a way of manipulating the mechanical properties of a material by changing its structure.

“If you no longer think of a material in terms of its bulk material properties, but in the range of properties possible with different microstructures, you open a huge range of possibilities that you never had before,” Porterfield stated.

Porterfield noted that there are yet many applications of lattices waiting to be discovered, and he is currently teaching a course on design for additive manufacturing (DFAM), that may accelerate the adoption and maturity of these applications.

Nominations for the 3D Printing Industry Awards 2018 are only open for another week. Submit yours now.

Are you inspired enough to design this year’s trophy? Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design now to win a 3D printer.”

For more stories on 3D software and parametric design, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a lattice pipe designed using Crystallon. Photo via food4rhino.