Researchers from University College London (UCL), Imperial College London (ICL), and Universitá Campus Bio-Medico di Roma have developed a 3D printed device to study the sense of touch in babies. In doing so, the research hopes to yield insights into reasons why some newborn babies have difficulty breastfeeding.

Etienne Burdet, Professor of Human Robotics in the Department of Bioengineering ICL, explained, “We found that conventional sensors were not practical, [so] we developed a dedicated sensor and packaging using 3D printing.”

The science of touch

Using a method called rooting, a newborn baby rests its face on their mother’s breast to find the nipple in order to feed. Thus, measuring brain responses to facial touch can aid in the understanding the brain development in newborns. However, premature babies may have difficulty feeding due to the underdevelopment of their facial sensitivity.

The research, co-led by UCL, aims to delve into facial somatosensation, the sensations of touch, temperature, body position, and pain recognized through neural receptors in the skin. According to the study, “facial somatosensation is critical for breastfeeding in very pre-term infants, born up to three months early.” Dr. Lorenzo Fabrizi, Senior Research Fellow, UCL Biosciences said:

“This research provides a way of understanding how pre-term babies process touch information and could help medical professionals to make informed decisions relating to their development.”

“We’ve proved that we can record the sense of touch from the face. This means that for premature babies, it is possible to study how they process the tactile information that they receive from the face, how this changes as they mature and whether disruption of this process might lead to longer-term feeding problems.”

The 3D printed sensory device

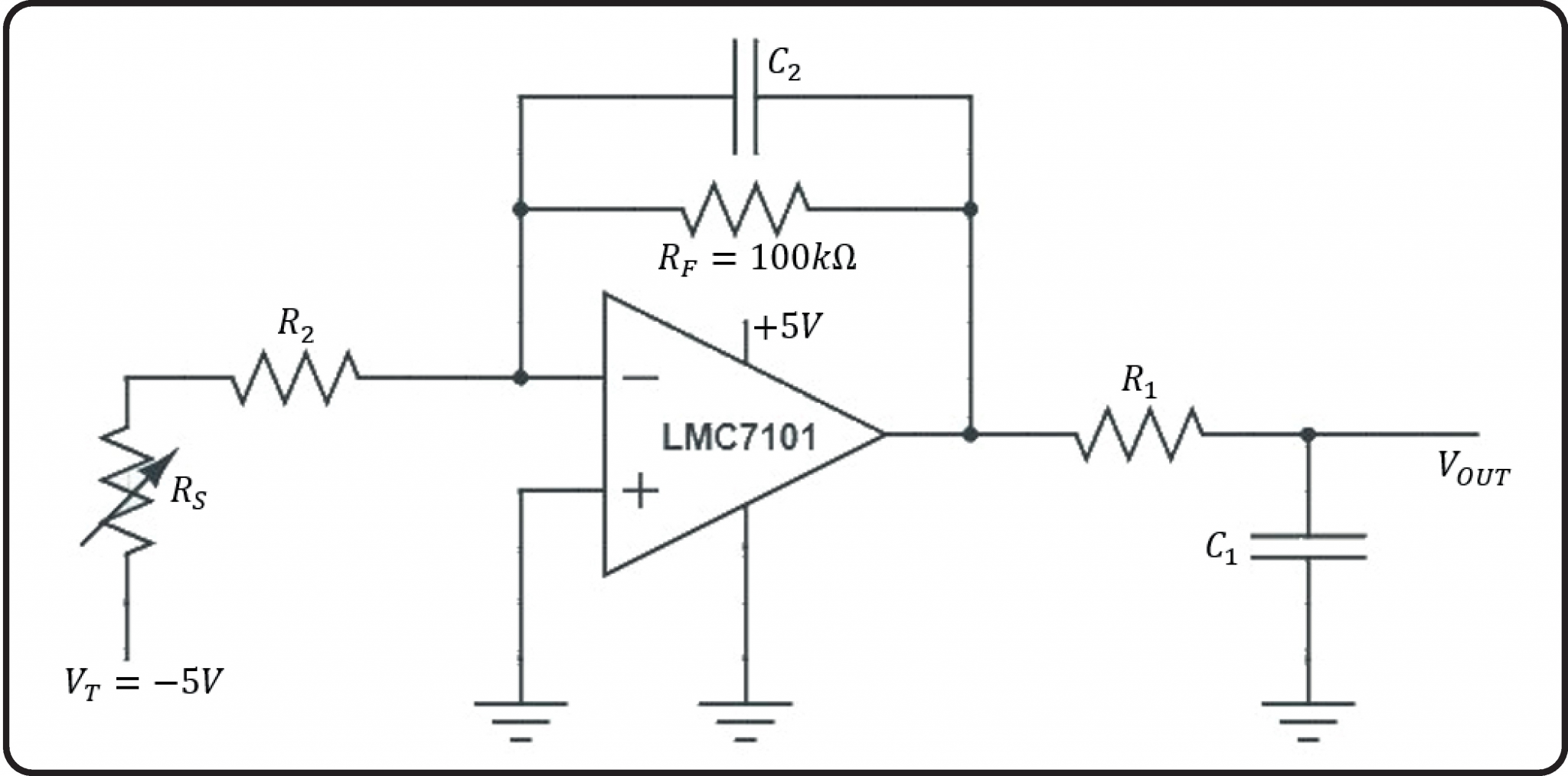

Using electroencephalography (EEG), a monitoring method to record the electrical activity of the brain, the researchers designed a custom-made 3D printed circuit board (PCB) using Autodesk’s Eagle CAD software. The PCB was then manufactured by OSH Park, a U.S. additive manufacturing service bureau.

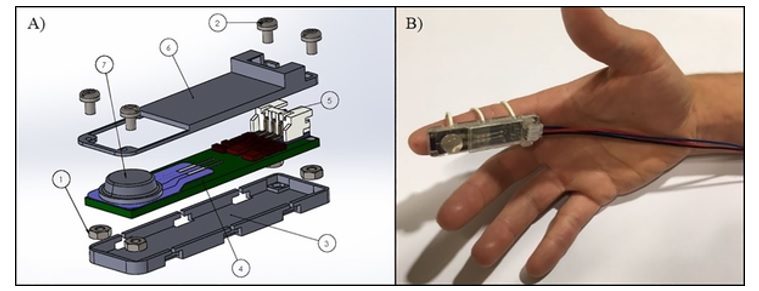

The board, with compact dimensions of 53.5 x 13 x 1.6 mm³, is made on two layers with two pin sensors and all the components placed on the top layer. Then, using a Stratasys’ Objet30 Pro 3D printer, which has a resolution of 0.1 mm, the researchers placed this board between upper and lower casings.

Three rubber bands are placed in the lower case enabling the user to wear the device under their finger. The device is also covered by a clinical glove. “We had to develop a stimulating system that was safe to use on the delicate face of the babies and acceptable to their parents,” explained Professor Burdet,

“We used an iterative design approach to develop a seamless wearable device that can measure a natural finger tap to the skin.”

Testing the 3D printed sensorised device

Once produced, the device can be used to lightly tap a baby’s cheek to activate brain responses. In this particular case, it was tested on seven babies typically seven days old at UCLH’s postnatal and neonatal wards. The researchers found that “tactile stimulation using the wearable sensor was well tolerated by every infant.” Furthermore, it was deduced that the sensorised finger could record the force applied with each tap.

UCL, ICL and Universitá Campus Bio-Medico di Roma’s research was supported by the UK Medical Research Council, European Commission grants, and a UK EPSRC MOTION grant. Ethical approval for the tests conducted was obtained from the NHS Research Ethics Committee.

“A novel sensor design for accurate measurement of facial somatosensation in pre-term infants,” is published in the PLOS One journal. It is co-authored by Alessandro Donadio, Kimberley Whitehead, Franck Gonzalez, Elisabeth Wilhelm, Domenico Formica, Judith Meek, Lorenzo Fabrizi, and Etienne Burdet.

Keep up with the latest research involving additive manufacturing by subscribing to the 3D Printing Industry newsletter. Also, find us on Facebook and like us on Twitter.

Search and post 3D Printing Jobs for new opportunities across additive manufacturing,

Featured image shows the 3D printed sensory device. Image via UCL.