Recently, Mike broke the news about Branch Technology’s C-Fab project for the future of architecture. While that is primarily based on a Kuka arm device, I started to think about some of the other large-sized 3D printing projects in the making and, more specifically, about the 3D printers behind them. While most people generally associate 3D printing with small size objects, the truth seems to be quite different. In fact, there seem to be two diametrically different concurrent trends in the industry. One is towards printing with the finest resolutions and the other is aimed at printing the largest sizes possible.

While they are fewer, numerically, the large size 3D printers seem to draw more interest. So, I figured that, to continue our Top Ten series, we should go find out exactly which are the ten largest 3D printers in the world. This time it is a “real” top ten as I counted close to 20 3D printers with build sizes of around 1 cubic meter and above. It is also based on an objective criteria: build size capability. The only high profile project missing from our list is Dr. Behrokh Khoshnevis’s Contour Crafting, pictured above, as it proposes a process more than a specific 3D printer.

So, if you are thinking of starting that new 3D printed boat project (like my friends here in Sicily at LivreaYacht), or concrete doghouse and furniture (like my new friends at ConcretePrinter), these are some of the machines you might want to look at and confront with.

10. Norsk Titanium’s Direct Metal Deposition

2.6 – 3.1 cubic meters / 94 – 112 cubic feet (available for service)

Norway’s Norsk Titanium (NTi) is currently in the process of opening a metal 3D printing facility in the United States, which will feature the company’s Direct Metal Deposition technology. DMD relies on a plasma arc to weld titanium wire directly onto a substrate until it reaches near-net-shape and NTi’s system is capable of 3D printing parts up to 120 x 120 x 180 cm in size, though the maximum length possible they say is 215 cm (that’s 4′ x 4′ x 5.9′ or 7′).

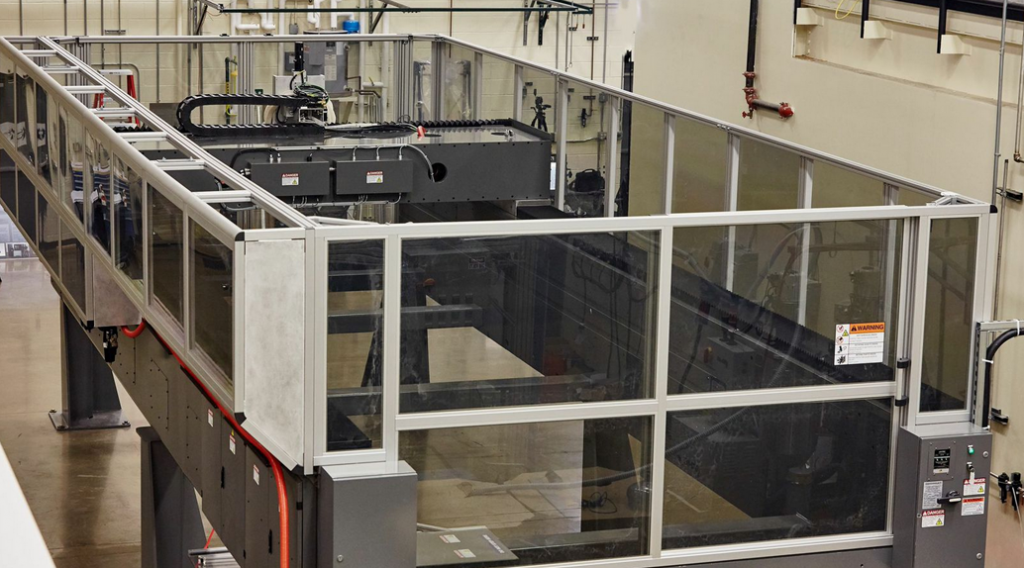

9. ExOne Exerial

3.696 cubic meters (3,696 Liters) / 130.52 cubic feet (available for purchase)

The Exerial will have a double chamber working volume which will measure 3.168 liters, making it one of the biggest 3D printers in the world. ExOne uses its own binder jetting technology to work primarily with metals, ceramics and sand, which is used exclusively for serial production of sand cores and molds. On top of its size, the Exerial system is 3-4 times the speed of the next largest machine from ExOne, the S-Max.

8. voxeljet VX4000

4 x 2 x 1 m: 8 cubic meters / 282 cubic feet (available for purchase)

The largest industrial machine currently on the market is voxeljet’s VX4000, which uses the company’s binder jetting technology primarily to 3D print sand casts as large as 4 x 2 x 1 meters (a volume of 8 cubic meters),

7. D-shape:

9 cubic meters / 317 cubic feet (available for projects/studies/research)

Designed by Enrico and Riccardo Dini, this 3D printer uses a binder jetting process. It deposits layers of a particular artificial sandstone and then creates the construction layer by applying a binder. Compared to other cement 3D printers it offers even greater geometrical freedom.

6. Sciacky EBAM 300

112 cubic meters / 368 cubic feet (available for purchase)

Sciaky’s largest available system is the EBAM 300, which uses a high power electron beam gun to melt a 3 mm thick titanium filament to near net shape, with standard deposition rates ranging from 7 to 20 lbs. per hour.

5. KamerMaker

14 cubic meters / 494 cubic feet (available for service)

The KamerMaker was one of the very first large-scale 3D printers to make headlines. It was also the first to use RepRap FFF-type technology to build a house on the canal in Amsterdam. DUS Architects and Fiction Factory, the companies behind it, have just added a second KamerMaker – with twice the original print volume – to speed up construction. The first KamerMaker was already printing at 240 mm/s.

4. WASP GigaDelta

Cylindrical, 8-10 meters / 26-32 ft tall (in development)

Ever since it started making 3D printers, WASP’s founder Massimo Moretti has had the dream of creating a house 3D printer which can construct habitats using soil and minimum energy on location. To do this, the company has built progressively larger delta 3D printers with special extruders. When it will be completed, the GigaDelta model will be 12 meters tall.

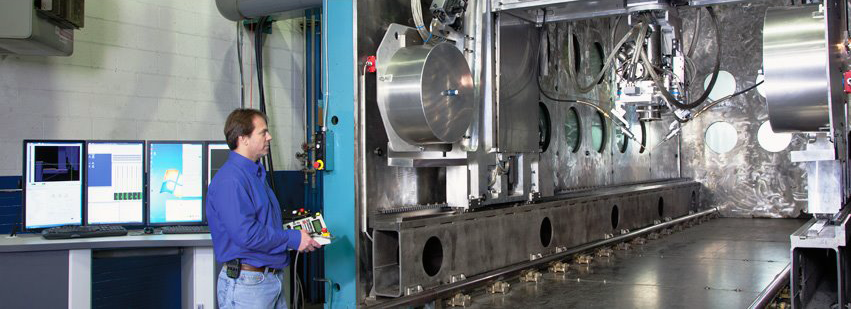

3. Cincinnati Incorporated’s BAAMCI

25 cubic meters / 930 cubic feet (available for service)

You may recognize the the BAAM (Big Area Additive Manufacturing) machine from Cincinnati Incorporated for its use in 3D printing cars. The BAAM printer was designed specifically to 3D print the Strati car for Local Motors, with help and technology licensed from Oak Ridge National Laboratory. The size and speed allow large parts to be made quickly using thermoplastic materials, which makes the process particularly low-cost. It also has open architecture for material vendors, which means that it can offer more alternatives. And BAAM is in the process of getting even bigger, as Cincinnati works on their next version, nicknamed Bertha.

2. BetAbram P1

288 cubic meters / 10,170 cubic feet (available for purchase on demand)

Slovenian company BetAbram produces, upon request, a series of three house printers that can 3D print habitable structures from a CAD file. The machines can print layers of 25 cm, but are working up to even thicker layers for added speed. Prices start at just €12,000 for the basic P3 model. The company is working on 3D printing a two-story house at some point this summer.

1. Winsun

2,466 cubic meters / 87,120 cubic feet (available for service)

When discussing large-sized 3D printers, the largest one by far is that created by Winsun, in China, to build furniture, houses, and even five stories buildings. It uses recycled concrete from construction waste and the process is, thus, significantly more eco-sustainable than traditional construction. Here, it is definitely worth noting that there is some controversy about the company’s technology as it relates to Dr. Khoshnevis’s own technology, with the USC professor claiming IP theft.

Correction: This post previously misrepresented the specs of the Exerial 3D printing system from ExOne to be slightly smaller, as well as the availability of the machine. The article has since been updated to more accurately reflect ExOne’s largest machine, now available for purchase.