Melbourne-based Titomic, the provider of Titomic Kinetic Fusion (TKF) metal 3D printing, has partnered with fellow Australian space company Gilmour Space Technologies to produce ‘high-performance’ rocket and space components using additive manufacturing.

The two firms signed a Statement of Strategic Intent and Technical Development agreeing to cooperate across various fields within the global space industry. This will include the development and implementation of Titomic’s Digital Manufacturing Solutions, like TKF, to produce rocket and aerospace components for Gilmour Space’s launch vehicles.

Titomic highlights the significance of the agreement in relation to Australia’s future space economy & exploration activities. The company also states that the use of 3D printing and other advanced technologies is indicative of ‘Australian sovereign capability’ on a global scale. Jeff Lang, Titomic Founder and Managing Director, explains that “This is an exciting new development for Titomic to share a commercially strategic vision to deliver unique capabilities of advanced technologies to assure growth of the Australian space eco-system.”

“It’s also gratifying that Gilmour, one of the pioneers in the Australian space industry, has recognised the potential of the TKF process and wants to cooperate with Titomic to explore how we can fully utilise it to produce high-performance rocket and space components.”

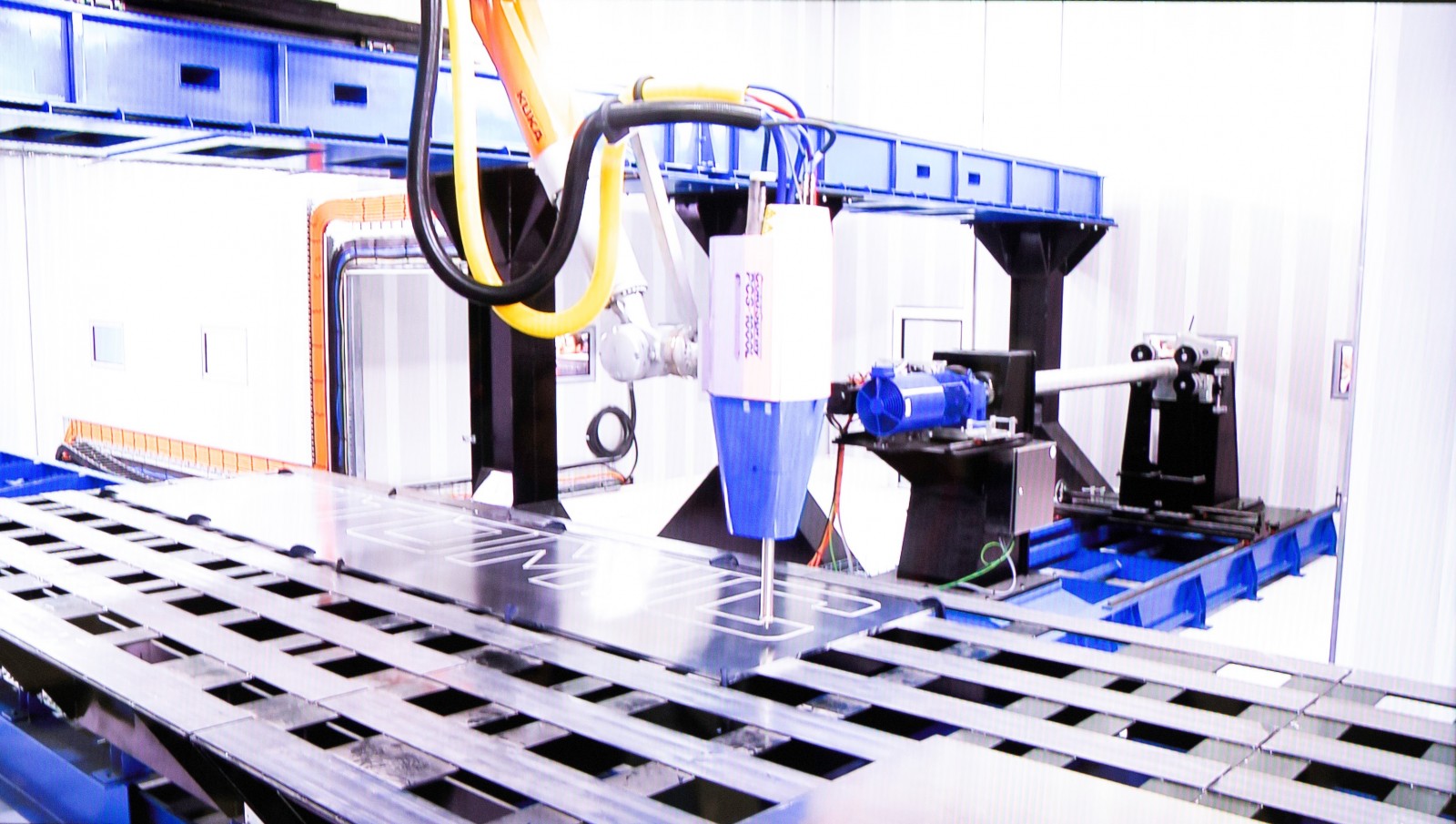

Commercializing the TKF additive manufacturing process

Founded in 2014, Titomic was established with the purpose of commercializing TKF, a solid-state metal additive manufacturing technology developed and patented by Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO).

TKF additive manufacturing has the ability to fuse multiple dissimilar metals together within a single part using cold-spray fabrication. With this ability, Titomic can potentially introduce different, high performance materials that would be otherwise impossible to make using other manufacturing techniques.

Titomic is the exclusive holder of the rights to commercialize the TKF process. Its route towards commercialization of CSIRO’s technology has seen the company sign a $1.8 million deal with UAV manufacturer TAUV, and agree to help reduce production downtime for companies in the mining sector with FLSmidth, a leading equipment supplier for the industry.

Recently in September 2019, Titomic further announced a powder supply agreement with GE Additive company, AP&C, a Québec-based materials producer, for the TKF process. The two companies also signed a Memorandum of Understanding (MoU) to develop materials for TKF systems. “Titomic is increasingly becoming a significant player in the global Aerospace, Defence and Space industries and by partnering with Gilmour Space it is further evidence that TKF technology has the potential for a multiplicity of applications for future industries to improve manufacturing affordability and sustainability of resources, ” added Lang.

Launching TKF additive manufacturing into space

Based in Queensland, Gilmour Space is a venture-funded firm founded in 2013 with the aim of making access to space cheaper for the global small satellite industry, and eventually human spaceflight and exploration. To this end, the company is developing new hybrid-engine rockets and associated technology to support the development of low-cost space launch vehicles, which uses 3D printed rocket fuel. James Gilmour, Co-Founder and COO of Gilmour Space, comments “Gilmour Space is developing new launch vehicles to support today’s global small satellite market, and this partnership could see us leveraging on Titomic’s innovative manufacturing processes to produce lighter and stronger components for our orbital launch vehicles.”

Its agreement with Titomic will see the two companies cooperate to perform R&D practices surrounding the fabrication of rocket components using TKF additive manufacturing systems. Both firms will also explore, design and develop a digital manufacturing process to deliver high performance rocket components that can potentially benefit Australia’s future space exploration activities.

Thanks to the capabilities of TKF technology, Titomic claims it is the only metal additive manufacturing process that can produce rockets and other space components in a single piece. “The Gilmour Space strategy, for lower cost access to launch satellites into space by affordable high-performance rockets, is in synergy with Titomic’s capability to provide an affordable alternative to traditional manufacturing by utilizing the unique capabilities of TKF technology,” concludes Lang.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a rocket from Gilmour Space Technologies. Photo via Gilmour Space Technologies.