SENER Aeroespacial, the aerospace arm of Spanish engineering and technology group SENER, and the Centre for Advanced Aerospace Technologies (CATEC) in Seville, have collaborated to develop a 3D printed metal antenna for the European Space Agency (ESA)’s PROBA-3 space mission.

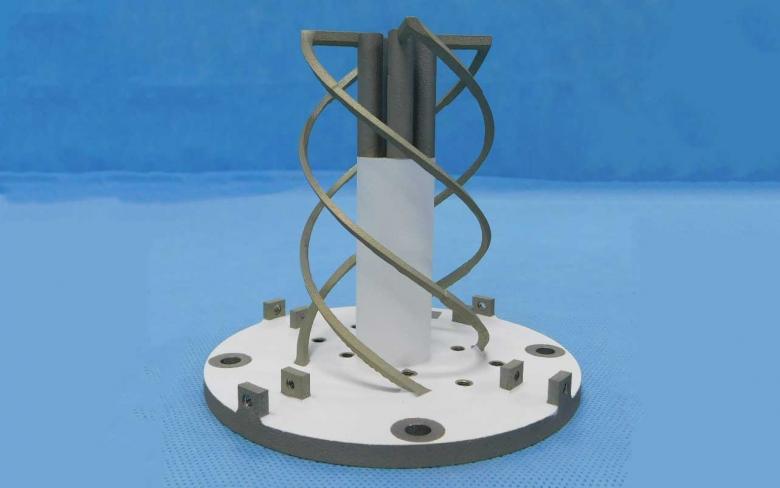

The helical antenna was 3D printed using an aluminum alloy, and represents the first instance in which SENER Aeroespacial has used metal 3D printing to produce such a device. It was manufactured for ESA as part of an entire delivery of telemetry and telecommand antennas for the PROBA-3 mission, for which SENER Aeroespacial is the prime contractor.

The antenna reaffirms the use of 3D printing as an alternative manufacturing process for SENER Aeroespacial and CATEC in situations where conventional technologies are not viable. The part is also reportedly the first additive manufactured antenna produced in Spain.

“SENER Aeroespacial came to us in 2016 with the challenge of developing a helical antenna for the European Space Agency, and with a real chance of flying,” commented Dr. Fernando Lasagni, Technical Director (Materials & Processes) at CATEC.

“The functional requirements of this product take to the limits additive manufacturing due to the dimensional tolerances for producing such a complex geometry.”

3D printing antennas for satellite space formation

Founded in 1956, SENER provides engineering services, equipment and system integration for space, astronomy, defense, aeronautics, and vehicle industries. The company’s inroad into the aerospace sector, and subsequent formation of SENER Aeroespacial, came in 1967 when SENER was contracted to design and build a rocket launch tower for the European Space Research Organisation (ESRO), forerunner of ESA.

Recently, SENER Aeroespacial has provided several antenna pointing systems for ESA’s main science missions such as BepiColombo, Solar Orbiter, Euclid and Juice. Currently, as the main contractor of the PROBA-3 mission, it is leading a consortium of European companies from more than 10 countries in supporting the mission.

ESA’s PROBA-3 is a precision formation flight mission intended to validate new spacecraft technologies while also carrying scientific instruments. As part of the mission, a pair of satellites will travel together in a fixed configuration in order to test the technologies for flying in formation, acting as one “large, rigid structure” in space. PROBA-3 is scheduled for launch in late 2020.

Validating the antenna for PROBA-3

For the PROBA-3 mission, SENER Aeroespacial and CATEC’s 3D printed aluminum alloy antenna was subjected to demanding qualification tests. CATEC, which has previous experience using 3D printing in aerospace, supported SENER Aeroespacial in the design and validation of the antenna specifically for compliance with ESA’s rigorous verification process. This resulted in obtaining the flight acceptance for the PROBA-3 mission.

“SENER Aeroespacial found the perfect partner and ally in CATEC to achieve the complicated goal of manufacturing and qualifying the first 3D printed metal antenna, with all the advantages that entails, while maintaining both radio-frequency and thermo-mechanical performance,” stated Esteban Celemín, Project Manager for the PROBA-3 antennas at SENER Aeroespacial.

3D printing at ESA

ESA has demonstrated an extensive effort towards utilizing the benefits of 3D printing for the space industry. Recently the agency undertook a project at the University Hospital of Dresden Technical University (TUD) where it proved the ability to 3D print biological matter in a space-like environment. Having successfully 3D bioprinted a specially formulated ink in minus 1g conditions, ESA hopes that the material could be used for the medical treatment of astronauts on long-term exploration missions.

In January 2019, ESA, alongside German technology group OHB SE, launched a consortium to develop a large-scale 3D printer for use in zero-gravity conditions. Named the IMPERIAL Project, the consortium includes German aerospace company Sonaca Group, Portuguese 3D printer provider BEEVERYCREATIVE, and Ireland’s Athlone Institute of Technology (AIT). The 3D printer will reportedly be able to produce objects larger than itself, and therefore defy build volume restraints in the process.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry

Featured image shows Proba-3 satellites forming artificial eclipse. Image via ESA.