It’s no secret that one of the industries that 3D printing technology has assisted the most since its inception is that of assistive prosthetics. Assistive devices are being modeled and produced by innovators across the globe, but one Maker, Cornelius Quiring, has decided that he isn’t going to wait for some 3D printing superhero to swoop down and help him with his own right hand disability.

When he was a child, Quiring was involved in a serious farming accident that tore a nerve in his spine and left him with extremely limited ability in his right hand. Although the accident left Quiring with a great disability, he refused to be defeated by it, thus creating The Hand Project, a 3D printed assistive glove that he hopes will restore the ability to fully use his right hand.

Once The Hand Project started to gain traction, Quiring then collaborated with a Seneca College mechanical engineer named Hargurdeep Singh (also known by the name Deep), who reached out to Quiring after hearing his story and reviewing his project design. Deep was an ideal candidate to assist Quiring in The Hand Project, he is involved with many 3D printing organizations and even runs the I AM 3D challenge, which encourages undergraduate students to push the limits of 3D printing technology.

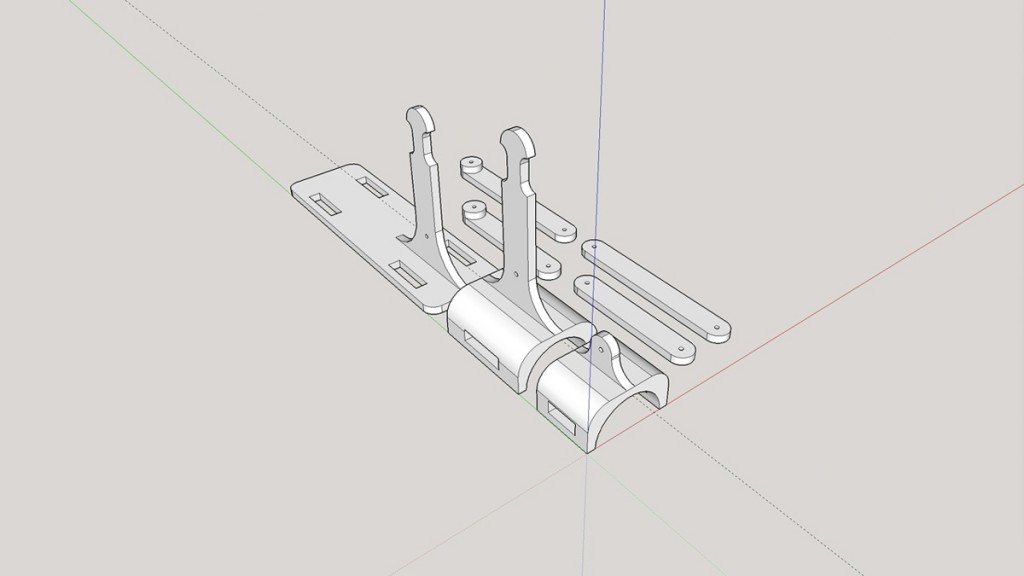

Deep and his team decided to help Quiring with the technical side of things, taking a 3D model of his hand, which gave Quiring the ability to focus on the aesthetics of the exoskeleton. Together, they eventually created an exoskeleton that allowed him to fully open and close his right hand. But the design was bulky and still imperfect, so Quiring decided to go back to the drawing board when he was suddenly approached by another source of inspiration.