What is the future of 3D printing? In 2022 3D Printing Industry will mark our first decade of reporting on additive manufacturing – we’re looking forward to a second decade, and so are the 3D printing experts we asked to help predict the future here.

If you want a near-term view of the current 3D printing trends to watch then read our previous article.

Which 3D printing materials are expected to thrive in the next decade? Will we see newly discovered 3D printing materials from AI-enabled computational alloy discovery where end users can specify required characteristics? How about the widespread application of metamaterials – materials with properties that do not occur naturally? How will sustainability be considered, an acceleration of efforts to produce bio-based polymers or recapture waste plastics and metals, returning resources to a circular economy?

Is 3D printing overhyped? Like any frontier technology, 3D printing has seen its share of futurist froth. Hype and buzzwords can be useful tools to attract funding, yet overpromising and underdelivering is detrimental in the long term. Marketers may use creative language to boost sales or encapsulate concepts in a digestible format, the counter-point to hype is providing a vision or goal to strive for.

Can 3D printing companies expect increased government scrutiny as soft state invention extends security concerns beyond defense and into others verticals such as energy, aerospace, or broader technology markets. Concerns over the semiconductor market are illustrated by friction between China and Taiwan’s TSMC, the European Chips Act announced at Davos, or Intel’s $20 Billion investment to build a “Silicon Heartland” and may herald a new era of protectionism. Export controls and ITAR restrictions are unlikely to be removed as tensions between Russia and NATO escalate over Ukraine. How might a tax on digital goods operate, and is the current moratorium on customs duties for electronic transmissions likely to be extended – if removed how will trends towards smart factories and collaborative business models react?

Soaring shipping costs and gummed-up supply chains driving a logistics crunch have prompted a reappraisal of manufacturing locations. Does additive manufacturing have a role to play in the reshoring projects, bringing manufacturing back to consumer nations, and will this take the form of the long-touted distributed manufacturing – or is production likely to be relocated yet remain concentrated due to economies of scale?

Back to the immediate 3D printing industry and how will the logo landscape change in the coming decade? Is consolidation in the 3D printing sector on the horizon, a succession of IPOs and a SPAC frenzy have poured capital into the sector. How will this money be deployed, R&D time horizons to bring innovation and new 3D printing technology to market can be contrasted with the shorter time frame some investors demand. Executives under new pressure to show incremental improvements on a quarterly basis may feel the temptation to supplement the bottom line via acquisition. 3D Printing Industry will be bringing updated data on 3D printing patents to these pages soon, will additive manufacturing retain a top ten position?

How can the additive manufacturing market be valued at $12 billion if SPAC activity in a recent 12 month period was over $11bn? And the market capitalization of one company using additive manufacturing is three times greater than the 3D printing industry itself? (Align Technology, NASDAQ: ALGN, market cap: $37.4 billion versus 3D Systems, NYSE: DDD, market cap: $2.2B)

The market via end users may do some of the work. Purchasing power works to seek out winning technology platforms among a sea of me-toos. Conversely, as the demand for additive manufacturing grows, a swelling market may raise all ships and both newcomers and incumbents will have access to a larger pie to be shared.

In an article about the future, it might seem odd to look at the past, yet parallels can be both illuminating and help plot a safer course. 1922 is often heralded as the birth of modernism, a workforce returning from global conflict and on the move through the great migration found work in the recently mechanized factories. Artists under the banner of futurism led by Marinetti had celebrated the movement and pace of machines whilst Dada and Chaplin’s Modern Times later kicked against the same. Woolf, Elliot, and Joyce put the internal stream of conscious thought onto the page, experimentation in the Harlem Renaissance saw modernism flourish in literature, music, and other art forms in the US and across the world. Might new design tools and technologies enable a modern-day renaissance and realization of creative urges? And how will the wider trends in society and macroeconomic forces interact?

Aldous Huxley’s Brave New World reflects the proclivities of his social circle but also, as artists are prone to do, imagines novel applications of technology. Although written almost a decade later, Brave New World has roots in a 1921 novel and expresses anxieties of the time alongside the perils of scientific futurism. Clumsily cherry-picking elements from the roaring twenties to draw parallels with the present decade is an enjoyable diversion, but it would be remiss to neglect the malignant forces such as frenzied speculation, overproduction, and maladaptive or absent control mechanisms that plunged the followed period into the great depression. This is a topic we will return to next week when additive manufacturing experts give their perspective on the broader technology landscape that will shape the coming decade. Will NFT backed STL’s be readily available in the metaverse and worked on by augmented reality engineers?

Subscribe to the 3D Printing Industry newsletter if you don’t want to miss the next article in this series.

Arno G. Held, Managing Partner, AM Ventures

In the next 10 years, Additive Manufacturing is going to establish its place as THE manufacturing technology which is going to support the transition to a sustainable and resource-efficient civilization. Today’s biggest potential applications – be it heat exchangers, lightweight structural components, or electric motors – will then be actual applications. To achieve this, industry participants will have realized that we all need to work together and overcome the big challenges of quality control, cross-platform repeatability, and recycling of materials.

Dr. Jeffrey Graves, President & CEO, 3D Systems

I expect mass customization will not only be an important trend for 2022 but the coming decade. While many organizations aspire to take advantage of additive manufacturing’s ability to produce large quantities of distinct parts, I don’t think every organization has fully understood how to integrate AM into its workflow. As we see a broader acceptance of additive alongside traditional technologies, I anticipate we’ll also see manufacturers of all sizes embracing AM for mass customization.

To facilitate the integration of AM into existing workflows, I believe machine learning will play a critical role. It is not enough to introduce design flexibility, speed to market, or supply chain efficiency offered by additive manufacturing. For companies to maintain their competitive position, they need to have a smart manufacturing strategy to introduce AM effectively and efficiently into their overall manufacturing workflow. As more companies adopt smart manufacturing solutions, I expect they will see how machine learning can enable autonomous manufacturing – thus helping improve productivity, and enhance capacity to introduce scalability and flexibility into processes.

Focusing our perspective on the next decade even further, I expect that we’ll continue to see additive manufacturing drive remarkable advancements in the transformation of healthcare delivery. AM has already demonstrated its power in this industry to enable patient-specific healthcare with unique solutions to create surgical plans and medical devices. I’m very excited about the next frontier in healthcare where bioprinting plays an important role. Over the past year, there has been a dramatic increase in the number of entrants to this field, whether it be research organizations or private and public companies. We’ve seen the scope of the research efforts broaden to include new printing technologies and new materials designed to assist in drug discovery, the creation of tissues, and hopefully one day, producing transplantable human organs. I believe we’re on the precipice of amazing advancements in this arena and look forward to what we’re able to influence and achieve as an industry.

Avi Reichental, co-founder & CEO, Nexa3D

AM will play a key role in reversing global warming through light-weighting, carbon footprint reduction from localization, lower energy consumption, and waste reduction, as well as transition to plant-based materials.

Over the next decade, AM will become a cost-effective and practical tool that covers the entire product life cycle from concept models to aftermarket spares and everything in between including the holy grail: volume production.

AM will go large, becoming an effective fabrication tool for planes, trains, automobiles, and homes – and also small for atomic structures.

We will get closer to a “replicator” state, particularly in bioprinting.

Kristin Mulherin, General Manager, Powder Products, Nexa3D & President Women in 3D Printing

Sustainability and the circular economy have been hot topics of 2021, and I only expect this to accelerate through the decade. Not only is additive manufacturing an enabler of a circular economy but adopting the tenets of a circular economy is necessary for the industry to fully thrive. Aside from the increasing environmental pressures, efficient recycling of materials, both plastic, and metal, is critical to reducing the costs for production-scale printing. The high cost of the raw materials for 3D printing is arguably one of the biggest hindrances of AM becoming a true mainstream manufacturing method. And until we can effectively and efficiently reduce or nearly eliminate material waste, and consequently bring these costs down, real high-volume printing will likely remain cost-prohibitive.

Didier Deltort, President, HP Personalization & 3D Printing Business

There is a historic shift in consumer behavior underway. And personalization and sustainability are lifelines for brands looking to stand out in increasingly competitive markets. Traditional product design, manufacturing, and supply chains are ill-suited to meet these demands. In the coming years, as we continue to improve additive manufacturing solutions, more brands, both small and large, will embrace new automated, higher performance, data-driven innovations that are ubiquitously connected to complex design, ordering, and logistics systems. This all enables us to bring both mass-personalization and sustainable manufacturing into a scalable reality.

Chris Connery, VP of Global Analysis, CONTEXT

Time and time again, shipment trends show that the industrial 3D printing market grows with each new innovation. Innovation can come by way of a new spin on existing technologies, by existing players expanding their product portfolios with complimentary technologies or by net-new technologies being introduced to the market. New products in new categories – especially when well marketed by established players, by well-funded start-ups – sell.

End-markets are always eager to investigate technological advances to try to find the silver-bullet technology to give them the competitive edge. Expectations are that in the same manner that Carbon’s spin on Vat Photopolymerization technology or Markforged’s spin on Material Extrusion technology helped the market to grow, other vendors will find new enhancements to the 7-core additive manufacturing technologies. In the same manner, as we are now seeing Stratasys expand its polymer portfolio to now include Vat Photopolymerization and Powder Bed Fusion, we can expect other manufacturers to self-develop or acquire tangential technologies and aggressively bring them to market.

Brian Thompson, CAD Division Vice President and General Manager, PTC

In the next decade, we expect to see the digital thread come into full force and become the DNA of smart factories, with additive manufacturing playing a major role in the transformation of end-to-end industrial production.

As AM standards continue to develop, and with the certification and qualification of more materials, processes, and parts, more industries will adopt end-use volume production. We will also start to see multi-material printing and part consolidation become more ubiquitous.

From a technological standpoint, we also expect to see major breakthroughs in the field of bioprinting and regenerative medicine, whether it is the creation of complex tissues, or even drug development.

Kathy Bui, Product Lead, Engineering Business, Formlabs

The last two years have shown us exactly how fragile and important supply chains are. AM/3DP has already stepped in to help support and strengthen supply chains, but the next decade will usher in an even greater role for AM/3DP in supporting traditional manufacturing techniques. Specifically, we’ll see more companies use 3D printing to create consumer-facing parts, produce custom manufacturing aids, and enable decentralized production. AM/3DP will never completely replace traditional mass production, but in the next decade, we’ll see the technology take on more and more processes historically handled by traditional manufacturing.

Franco Cevolini, CEO & CTO, CRP Technology

In the next few years it will be necessary to address the issue of sustainability. The fact that AM is already a leaner, “lighter” and agile method of manufacturing is certainly already an advantage over traditional technologies. But it will be necessary to work on sustainability at the production level of the AM supply chain: from the materials to the use of electric power, which must come from renewable sources as much as possible. This will be one of the themes of the future, too.

Stephan Kühr, Founder and CEO, 3YOURMIND

In terms of manufacturing in 10 years, I envision new collaborative business models facilitated by digital platforms and technologies around the world. AM/3D will be implemented at all manufacturers for prototyping, but especially, for mass production. Barriers related to AM knowledge, quality certification, data collection will be lifted. These new Industry 5.0 factories will be sustainable, connected, and digitized. Through this, I hope creativity will become limitless; new form manufacturing (additive, hybrid, etc.) will be fully integrated with artificial intelligence, robotics, and digital twins will push us to discover the limits of IoT, and ultimately, determine no limits exist! I can’t wait to see this!

Frank Roberts, President, 6K Additive

Technology across the AM supply chain from materials to machines to post-processing as well as software will significantly add value to organizations as more applications move to production. Specifically for materials, we see an ever-evolving suite of high-performance metal materials that will enable rockets to go faster and run at extreme temperatures, that will allow medical applications that will significantly improve patient care, and allow doctors to perform surgery with implants made from the most exotic materials. Materials will also be made from high-entropy alloys that today are in their infancy. And while new materials will emerge, the sustainability commitment from material manufacturers and customers will be as important as the quality and cost factors.

Kaj Fuehrer, CEO, enter2net.com

In the future, additive manufacturing will conquer ever-larger shares of the total manufacturing volume. A new driver is the stabilisation of logistics chains through local and decentralised manufacturing. On the way to a sustainable and cost-efficient implementation in the manufacturing industry, 3D printing will lose its special status as a new technology “where everything is different” and will be integrated into the complete value chain, especially using automation and industrial IoT concepts. This assumes that the major challenges regarding material costs and qualification, print speed and quality as well as integration of the AM processes in standard software will be addressed, which I firmly believe to be the case.

Joseph Crabtree, CEO and Founder, AMT

As we look forward to the next decade, we expect a period of consolidation in the AM industry. Several ‘traditional’ manufacturing companies will start to make plays in the AM space and increase in M&A activity will occur. We expect that a reset of the frothy markets of the last 2 years will drive this consolidation of companies with only those with viable long term business profitable growth sustainability being able to ride the wave. This will lead to the ultimate growth and expansion of the AM industry and will lead to 3D Printing being ‘just another manufacturing technology’ – I.e. the ultimate acceptance that we have all been looking for.

Dr. Robert Gmeiner, CEO & Chief Technology Officer, Cubicure

The current decade will likely see a transition from technology bets to an intense focus on measurable added value rooted in realistic production scenarios.

Vertical markets will be the first to feature sustainable AM success stories. While mergers will continue – technology-wise as well as company-wise – a genuine AM industry is about to rise.

In the past, the attention in polymer AM was clearly focused on FDM and powder-based printing processes. The biggest turnover in industrial AM production has however always been connected to resin-based 3D printing. The next decade will further reflect this economical fact: photocurable materials are quickly evolving into polymers fulfilling high-grade technical requirements for multiple industries. Individualized mass production will continue to play an ever-growing role in patient- and consumer-related products. At the same time, full series additive manufacturing of small and complex parts will grow tremendously in sectors such as electronics and connectors.

Production flexibility and risk reduction are essential for all industries even now and will remain so in the future.

Daeho Hong, Product Manager, nTopology

Through the next decade, mass customization will become a standard for many more applications than we see today (e.g. medical devices and high-end sports equipment). As AM material and production costs continue to drop, we will likely see some supply chain disruption as parts printed locally become more cost-effective than those shipped from global manufacturing hubs. We will also see an expansion of the AM materials portfolio, with the availability of new AM alloys, polymers, and hybrid/metamaterials. Advancements in additive hardware will enable printing with minimal to no human involvement, and many printers will enable freeform fabrication that builds parts from all directions instead of stacking layers in the z-axis.

Gil Lavi, Founder & CEO, 3D Alliances

For the next decade, I see two trends: the first one is the acceleration of R&D in the development of new AM capabilities, which will result in exciting technologies that will offer higher throughput, dedicated materials for specific applications, higher accuracy, and repeatability, or in other words, better compatibility for real production needs. 2021 was a big leap for many companies that raised funds/decided to go public when part of the capital is targeted for developing new products. The second trend is the adoption of AM in new applications in non-standard/traditional industries such as construction, food, fashion, space, and others’.

Oliver Smith, Founder, Principal Consultant, Rethink Additive

If the 2010s were the decade 3D printing grew up, the 2020s will be the decade it goes public. Just in the past 24 months alone, there has been a flood of capital into the industry that is driving both a stark acceleration of new platform developments, as well as stimulating M&A activity, and there shows no sign of stopping. I would argue that this renewed investment interest in the technology has been spurred by the significant degree of positive press demonstrating how 3D printing has provided solutions to critical part shortages and supply chain disruptions, but unlike the investment hype wave of 10 years ago, this second wave is sustainable with so many 3D printing technologies capable of being deployed in direct production or production support applications. The next ten years will be an exciting time for technology vendors and investors, with a wave of public offerings ahead (several successful private vendors such as Formlabs already publicly stating their interest to IPO) alongside a consolidation amongst new entrant and legacy vendors through M&A.

An additional trend we expect to see at Rethink spurred on by the increased exposure of AM as a result of pandemic supply chain disruption is set to drive explosive growth this year and for the decade rides off the back of this new wave of awareness; financial investments in technology vendors. Once again 3D printing is a front-of-mind technology when discussing market disruption and factories of the future, and this has led to a wave of acquisitions, investments, and IPOs. With such an influx of capital, we are already seeing an acceleration in time-to-market for new technologies and platforms, as well as M&As amongst legacy vendors. With several more highly successful AM vendors publicly stating their intention to go public, whether, through a traditional public offering or a SPAC, we should expect the trend of M&As and IPOs to continue strong into 2023 and beyond, with not all likely to be sustainable.

Mohsen Seifi, Director of Global Additive Manufacturing Programs, Martin White, Head of Additive Manufacturing Programs – Europe Region, UK, Alexander Liu, Head of Additive Manufacturing Programs – Asia Region, Singapore, & Terry Wohlers, Head of Advisory Services and Market Intelligence, ASTM International’s Additive Manufacturing Center of Excellence

Over the next decade, we predict that AM will play a vital role in the pursuit of sustainability, supporting the global shift towards greener methods of manufacturing. This trend will help support economic and environmental goals set by governments around the world. Methods of AM will continue to be driven by market pull, such as the Net-Zero Carbon applications, particularly in transport and heavy industry.

On the applications front, the demand will continue to grow for larger parts, such as titanium bulkheads in aerospace, and large castings that compete with AM alternatives (both powder bed fusion and directed energy deposition). This will widen the supply chain, reduce the lead times for development of new platforms, and ultimately continue to offer reductions in cost.

Dr. Johannes Homa, CEO, Lithoz

With additive manufacturing growing into an ever more established production technique, we are already seeing companies successfully integrate this powerful technology into their workflow to complement their existing manufacturing methods. Soon, we will be seeing the creation of geographically independent, yet globally and digitally connected, production sites, which will be able to enter simultaneous serial manufacturing thanks to the digital production capabilities of 3D printing.

Additionally, there will be a stronger focus on quality and reliability in serial production than ever before. As more and more companies enter into serial production, it will become necessary for there to be a higher level of quality assurance and trust in the efficiency and capability of the additive manufacturing process; therefore, it will become a top focus of companies in this industry to make every step as reliable as possible. Finally, and as a result of the previous point, there will be a growing level of automation in the industry, eliminating human error and making the entire process more efficient and easier for both producers and customers.

Roger Uceda, Technology Transfer Director CIM-UPC & Co-Founder BCN3D

I strongly believe we will finally see mass production made with AM technology, and not only for custom products or high added value products, but for serialized products. For that, we still have some challenges to be addressed, such as first-time quality and final part price.

Henrike Wonneberger, COO and co-founder, Replique

Options for AM materials are already growing, with metal and high-temperature polymers in FDM printing being developed. Improvements in AM have already prompted a movement from prototyping to a main manufacturing method but we anticipate AM being used not only as a replacement for traditional manufacturing but as a whole new supply chain approach in the coming years. AM will be integrated into a holistic and secure platform where individual steps of 3D printing are combined into one process, from ordering the part, to delivering it to the customer. Advancements in AM software have improved quality control and now allow us to predict warping and excessive thermal stress before printing, minimizing printing defects and wasted materials. Simulation can be used to get the most out of materials, allowing designers to create shapes that would never be possible without 3D printing, developing new products that score with topology optimization and weight reduction.

Rush LaSelle, Senior Director, Additive Manufacturing, Jabil

The next decade of manufacturing will bring major transformations in digitized processes and applications implemented by global factories. The emergence of a more comprehensive digital ecosystem will propel the entire additive manufacturing industry forward by making small-lot production, including a batch-size of one, truly cost-effective for more consumer-oriented products. As a result, expect to see a democratization of manufacturing and localization that will better serve customers.

Luis Folgar, EVP Americas, AMT Inc.

The portfolio of plastic materials available for 3D Printing will have no limitations. Part quality and throughput will continue to increase proportionally. Due to lessons learned from supply chain disruptions, 3DP end-use parts will be the go-to only viable choice for many OEMs from automotive to medical. 3DP OEMs will offer fully automated end-to-end systems and technology solutions that keep the digital thread from design all the way to post-production and inspection of any 3D printed part.

Filemon Schoffer, co-founder and CCO, Hubs

New materials and material composites, lower pricing, and mature post-processing options will make it more viable to integrate 3D printing into production cycles. As the technology keeps developing, it provides an ever more competitive alternative to injection molding for low-volume plastic parts.

Even more exciting, advanced material composites, combined with the ability to produce highly complex geometries, will open up new manufacturing possibilities that have been impossible to unlock with traditional technologies (this is already happening!).

Kwang-Min Lee, Vice President, Carima

AM/3DP technology use cases and market size have been extremely expanded, but the application of AM/3DP for end-use part manufacturing in the machinery industry still has a way to go to full maturity.

In other words, apart from the use purpose of 3D prototyping, education, and R&D, many industrial companies are working to use and utilize it as alternative technology against their traditional production methods such as cutting processing and injection molding, but the thing is that 3D printing output speed is still a stumbling block compared to those methods.

Therefore, to target traditional production methods, the development of differentiated 3D printing technology is indeed needed to be prepared urgently, and it is likely that the AM/3DP market will be maintained for the next decade.

To prepare for this, almost all 3D printer manufacturers have been investing a lot of time and money in the development of the fastest 3D printing technology, but it is still difficult to get high-precision and repeatability at the same time.

The thing is that we, Carima have developed the C-CAT(Carima Continuous Additive Technology), which is the world’s fastest 3D printing technology that improved productivity by at least 20 times compared to the existing DLP technology, as one of the global 3D printer manufacturers. And we successfully demonstrated it in the formnext 2021. We aim to modernize it and commercialize new 3D printers with that technology in the next 1-2 years.

The C-CAT is the fastest 3D printing technology that enables DLP 3D printers to output 1cm per minute (60cm per hour) with high-precision and reproducibility. Our R&D team has improved the damage generated at the output to minimize release forces, and significantly lowered release energy compared to the existing process. With that improved C-CAT, more stable continuous additive manufacturing has become possible.

As I mentioned earlier, improving the 3DP working process and more robust 3DP technology development are absolutely necessary to secure a portion of the existing plastic or rubber part production industries. For that reason, based on our C-CAT and bespoke manufacturing, we plan to lead the era of mass customization for end-use products by accelerating the development of new 3D printer that can output various parts across industries such as glasses, shoes, consumer goods, and automotive interior and exterior parts, with printing at a speed of several tens of centimeters (CM) per hour.

Amir Veresh, Founder, eConsulting Ltd.

I am quite certain that within the second half of the coming decade, additive manufacturing will become an important, legitimate (regulated and having its own standards), mainstream manufacturing method. It will improve the way products are being made, as in many cases it will complement traditional manufacturing methods, and for other products, it will be the enabling technology and main way to manufacture. Replacing traditional mass manufacturing with additive manufacturing requires proper justification that can be cost, environmental considerations, supply chain, improved functionality, etc. (there is no necessity to prioritize these different possible justifications). It will take time until OEMs design their products in a way that can justify the migration from traditional to additive manufacturing. This will happen with the improvement of technologies and progress of design for additive manufacturing education. Many initiatives will fail due to poor justification, and over time, a growing number of applications will prevail.

Additive manufacturing will be capable of processing more currently used standard industrial materials and probably, some proprietary materials made for additive manufacturing will be qualified to be used for products manufacturing.

Additive manufacturing will enable distributed manufacturing, thus improving supply and value chains, adding value to customers, and supporting the well-being of our planet.

Based on existing trends, I expect that breaking into the mainstream will continue by identifying more low volume – high mix products that will gradually replace existing (not customized) mass-manufactured products. This is an exponential process that will significantly accelerate over time. As has already been indicated in different articles, a good step towards becoming a mainstream manufacturing method, additive manufacturing must adapt itself to address the huge pain of spare parts inventory, by a holistic solution of digital inventories backed up by distributed local digital manufacturing.

Additive manufacturing will become an integral part of advanced PLM that will be deeply IoT and I4.0 oriented.

Jordi Drieman, 3D Application Specialist, Mimaki Europe

Over the next decade, I predict that full-color 3D printing will be picked up by small to medium-sized businesses, as printers such as our 3DUJ-2207 become more cost-effective as well as more conveniently sized for an office space.

Automation is another exciting technology that I see becoming commonplace across the whole printing sector, as the expectation for shorter delivery times grows and with it the need for a 24/7 runtime.

Dr. Alvaro Goyanes Goyanes, Co-founder & CEO, FabRx

In the next decade, 3D printing will be fully integrated in hospitals and pharmacies to prepare medicine for some challenging to dose medicines and for clinical and preclinical studies. One of the revenue streams for big pharma companies will be selling ink cartridges with drugs to prepare personalized medicines on demand close to the patients. This will increase personalization of the medicines increasing acceptability and effectiveness, reducing side effects.

Andreas Langfeld, President EMEA, Stratasys

AM will find its place as the unique and only production technology in selected use cases. There will be a common understanding that certain parts must be produced additively because of lot size, need for customization, need for on site production on demand. This standardization of AM as the preferred production method is seen today in mobility, aerospace, dental and medical, but it will spread into other verticals and become the new normal of “how we produce” certain components.

Andre Wegner, CEO, Authentise

New Technology: One thing is clear – technology evolution won’t stop now. We’ll not only see continued incremental improvements to existing technology platforms, but completely new platforms and technology sets.

Intent Based Design: Partially to enable the rapid deployment of new technology platforms, and to improve speed to market for new ideas we’re going to become increasingly less reliant on CAD and other design tools to communicate our intent but instead focus on semantics that can capture our pure intent. This intent will in turn be used by a myriad of software tools, esp generative designs, to determine the final shape under the influence of other parameters such as available machines and materials.

Full in-process AI: Transposed, intent based design means that findings from the latter part of the process (for example observed measurements in the additive process or in testing) can influence new design versions automatically, or change parameters. This creates a full end-to-end in-process rather than just limiting in-process technologies to particular machines.

Martin Hermatschweiler, CEO, Nanoscribe

People commonly tend to overestimate what they can achieve in 1 year and to underestimate what can be achieved in 10 years. 3D Microfabrication will be an innovation driver. Size matters – particularly on the small scale. And material matters, too. We will see a plurality of applications maturing from basic to applied research until they eventually reach industrial-grade maturity with a steep technology readiness level development (TRL). Start-ups in particular will identify niches early on and make them grow. A vast choice of materials will emerge and reach industrial grade, may it be biomaterials such as bioinks, and biodegradable materials or technical materials beyond high-performance polymers, including glass and ceramics. Multi-material 3D printing concepts will also become industrially applicable. The computational design abilities and the ease of use of Two-Photon Polymerization will shorten the development cycles from a design sketch to a ready-to-use product from years to weeks.

Gareth Neal, Customer Applications Manager, Advanced Applications, Technologies & Fluid, Xaar

The use of multi-material, multi-functional metallic, ceramic, and polymeric products that are enabled by improved inkjet printhead capability, will develop further end-use applications as design teams become more aware of how functional fluids can offer production solutions and provide some significant advantages to manufacturing challenges.

Similarly, the adoption of inkjet as a manufacturing technology in the numerous coating applications currently conducted by analogue techniques, will deliver multiple benefits, from production efficiencies to far more sustainable production processes.

Indeed, sustainability is at the heart of these technological developments, as AM and 3DP manufacture delivers both reduced energy use and material waste through the highly precise jetting of fluids and inks across its many applications.

Xavier Martínez Faneca, CEO, BCN3D

Consolidation will be key in the coming years. The landscape of companies in 3D printing will most definitely undergo a complete transformation in the next decade. Technology will evolve towards high-capacity solutions that will lead to more autonomy in the hands of the final customers. I expect that, during this 10 year period, AM can really fulfill the promises that have been outlined in recent years to become the main manufacturing technique for creating end-use parts.

John Barnes, Managing Director, and Laura Ely, Director of Programs, The Barnes Group Advisors

AM will become less special, perhaps even boring. Boring is good for series production and series production is good for AM. We’ll be happy, free, less confused, and lonely – simultaneously.

Machines – More diversification as the industry learns about binder jetting, directed energy, and the other ways to make layers.

Materials – Our two hopes here are: 1) A deeper understanding of how feedstocks work in the different processes and 2) The advent of more advanced polymers to push the performance envelope in polymer AM. (We see a shift to higher-value materials, much like metal AM.)

Digital – Improved software is on the horizon; it will be integrated across the AM workflow and smarter, perhaps even artificially intelligent. Machine Learning will become a standard tool for the industry to learn, adapt and overcome recurring types of issues.

People – As more people learn AM and appreciate the importance of MfAM/DfAM, the skills gap will be minimized; the existing workforce will continue to learn, and they will be supplemented with new grads coming out of trade schools and colleges for whom AM is already a tool in the toolbox.

David Iacovelli, Regional Director EMEA, EOS

Other than AM’s clear advantages to other manufacturing methods in terms of sustainability, we will see it compete and replace technologies that are commonly used today. Additive will become the dominant mass-manufacturing technique. The complete automation and digital workflow that is possible with polymer additive manufacturing, in particular, will see it replace high volume, serial production techniques that require both high resolution and high productivity at low cost. Our own Fine Detail Resolution technology will have an impact in this space, but it is also true of other technologies such as Laser ProFusion which will move the industry closer to tool-free injection molding.

The second innovation that we expect to see is a wider industry move towards digital warehousing and on-demand production for spare parts. It will allow companies to dramatically reduce the costs associated with their after-market operations while creating new businesses focused on providing parts and services manufactured locally for a host of consumer and industrial products.

Over the coming decade, we believe that we can also expect further consolidation in the market to a few larger players. But alongside this, will come much better interoperability, which will bring increased competition to the market, by making it much easier for manufacturers to move between, and mix competitive technologies based on their needs.

Nora Toure, Founder, Women in 3D Printing

Even though I wished this was a 2022 prediction, it will probably take more than a year to get there. However, I am hopeful that we should see a normalization of diversity and have more people of color represented in key roles and at every level of any given organization.

In terms of technology, continuous improvement of post processes and materials more broadly should be expected. I wouldn’t be surprised if AM in the next decade wouldn’t look exactly like what we see today.

Sylvia Monsheimer, Head of New 3D Printing Technologies, Evonik

I hardly think we will see “big bang” application in the coming decade. Rather, I expect to see specific approaches to series production that will add up to huge industry success. A successful series production with additive manufacturing will require this specialization with respect to process parameters, machines, and material to boost 3D printing against conventional production. I expect to see new technologies! There are so many experts now working to overcome the challenges of the existing solutions. It will be an exciting decade.

Fedor Antonov, CEO, Anisoprint

The major technological trends will be in further development and improvement and increasing the technology readiness and adoption – the technologies that have already caught the attention of the market and already were developed. I don’t see any significantly new technologies to emerge within the next few years and most likely it will be about consolidation, maturing, improving, entering the market with existing technologies. New technologies will find a new niche and it’s about stable market growth and disrupting traditional technologies. Every group of technologies and machines will be focusing on a certain niche where it performs best. In the future, 3D printing technologies will be more narrowly specialized: tailored even more for certain industries and problems in different niches.

The next decade will bring the best opportunities for 3D printing to enter new emerging markets such as commercial space, drones and UAVs, robotics, urban mobility, and many others that will grow fast. They will be the main driver for the growth of enabling technologies such as 3D printing. This is where these new players will be able to win the competition over the old ones – by being more flexible to apply 3D printing. And apply new technologies that are more sustainable and allow to manufacture better quality: more lightweight parts customized on demand that solve the supply chain issues in addition.

There is this synergy between the emerging markets and enabling emerging markets such as 3D printing and new hardware emerging markets such as the ones that I just mentioned. These markets still grow at a very impressive rate from 20 to 30 percent and they will altogether reach a trillion Dollar in the next decade and obviously, the 3D printing market will continue to grow at the same speed and we will have a significant piece in this market.

Dr. Ingo Ederer, CEO, Voxeljet

The past year was characterized by acquisitions and consolidation processes since the space is extremely fragmented. We believe that this will continue over the next couple of years. Even though additive manufacturing has been around for about half a century now, we are currently recognizing an incredible maturing of the technology and the ecosystem around it.

Especially during the pandemic and in the face of climate change, additive manufacturing could position itself as a technology that can address the challenges posed extremely well. In terms of supplementing existing production processes in order to meet volatile surplus demand and on demand, on site production and in terms of lightweight construction and resource efficiency. What is still lacking however are the possibilities for automation and broader application opportunities due to the lack of new materials and standardization certification. These elements will be the focus of the industry for the next decade and are necessary to really push AM into a viable mass production technology.

With the increased adoption of AM there will also be a growing demand for skilled workers and AM-specific education while we already see the first AM-focused courses in schools and universities, the whole engineering mindset will shift towards more resource efficiency and sustainable engineering. This also will include the development of enhanced software solutions.

James DeMuth, Founder & CEO, Seurat

The price of parts produced by LPBF will significantly drop to compete with low to mid-volume casting and machining applications while maintaining the high quality and benefits of AM that we’re all accustomed to today (and plus more). Mass manufacturing of AM parts will become commonplace.

Dr. Joshua Pearce, John M. Thompson Chair in Information Technology and Innovation, Western University, Canada

Many predictions of having a 3D printer in every home have yet to come to pass, but the steady and quiet rise of distributed manufacturing with 3D printers at the household scale is undeniable. 3-D printing filament is now classified as an “Amazon Basic” along with batteries and computer paper. The technology I think will tip the scales for distributed manufacturing over the next decade is distributed recycling and additive manufacturing (or DRAM for short). Several open source technologies — from recyclebots that make filament to direct waste 3D printers — have matured that allow us to use 3D printers in our own homes to recycle waste plastic into valuable products. DRAM saves people real money. It allows consumers to make custom products for less than the sales tax in the US (6%) on conventional consumer products ranging from skateboards and toys to syringe pumps and arthritis aids. As more companies take advantage of the economics and make more DRAM technologies available to their customers, we can expect to see DRAM follow the growth curve of consumer 3-D printing.

Alessio Lorusso, CEO, Roboze

The impact that Additive technology will have on the future is the most exciting yet inconceivable thought. I believe the most critical and overarching theme that AM will continue to show revolutionary outcomes is in the response to sustainability strategies for our planet. The possibilities are infinite. Creating more on-demand local production, slashing transport emissions, and combatting production waste is only just the beginning. At Roboze, we look forward to supporting the innovators of tomorrow that will change our future for the better.

Ankush Venkatesh, Intrapreneur, Additive Manufacturing, Glidewell Dental

The coming decade will see AM mature in its role within the constellation of digital manufacturing. This will enable new innovative business models to take advantage of the suite of digital solutions. These solutions will be predicated on software platforms that will be modular, interoperable, and highly sophisticated. While it may, in part, drive multiple hyper-specialized solutions providers, it will push incumbents to focus on developing sticky, end-to-end offerings. We have seen this play out before in the personal computing industry (1980s – 2000) as well as in the smartphone industry (2000s – Present).

This decade will also see a significant move towards the edge. When we think of edge computing or point-of-use manufacturing, all of these have been enabled by significant advances in technological capabilities coupled with its increased and affordable access downstream. With these factors in constant rise, I truly believe this is the decade in which distributed manufacturing can be truly realized. Manufacturing at the edge is well on its way to becoming a norm; the FDA recently released a discussion paper seeking input from industry actors to help guide its formulation of policies and regulation of 3D printed point-of-care solutions.

Data will play a vital role in extracting maximum value from additive manufacturing. Information about process control, demand/supply trends, supply chain flexibility, and carbon emissions will increasingly feed systems that are able to digest these large data and obtain actionable insights.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

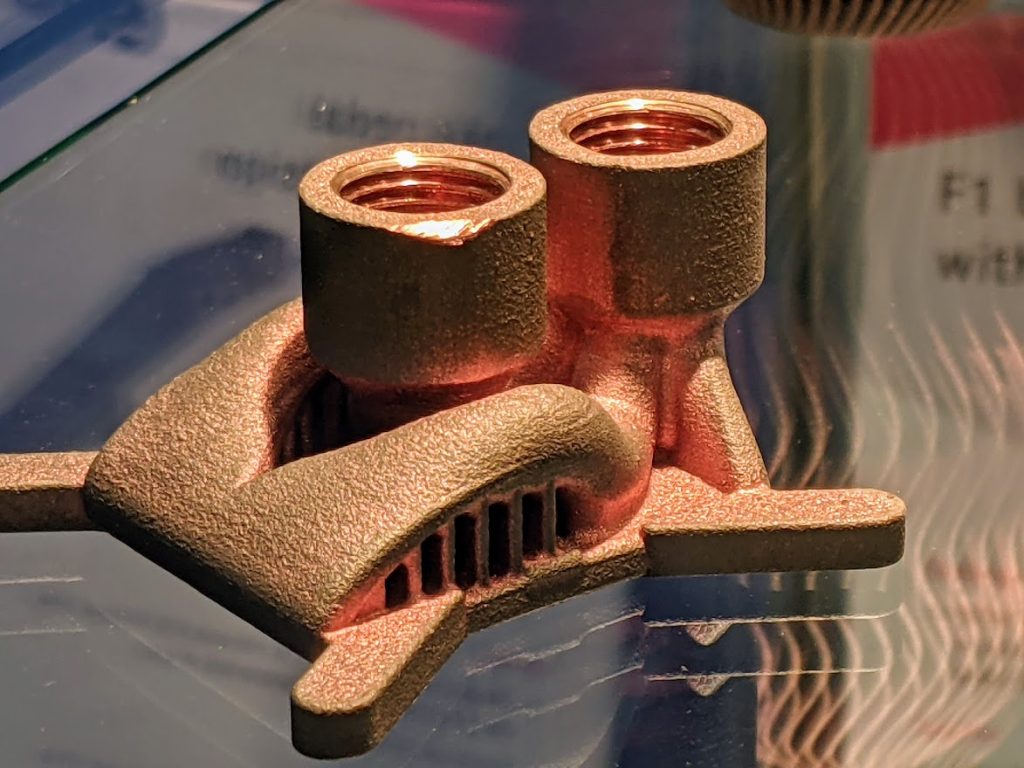

Featured image shows EOS 3D printed copper alloy Gaming CPU cooler. Photo by Michael Petch.