Ahead of its (delayed) annual meeting in Davos, Switzerland, the World Economic Forum (WEF) has published a white paper outlining a potential roadmap for rapidly driving the wider adoption of 3D printing.

Despite the “cycles of hype” seemingly surrounding 3D printing, the WEF says that “not all predictions and forecasts” about its potential “have become reality.” In order to make the technology more resilient, flexible and sustainable, the group has therefore used its paper to issue a seven-point industry call to action, designed to allow it to finally reach the mass-inflection point predicted in the early-2010s.

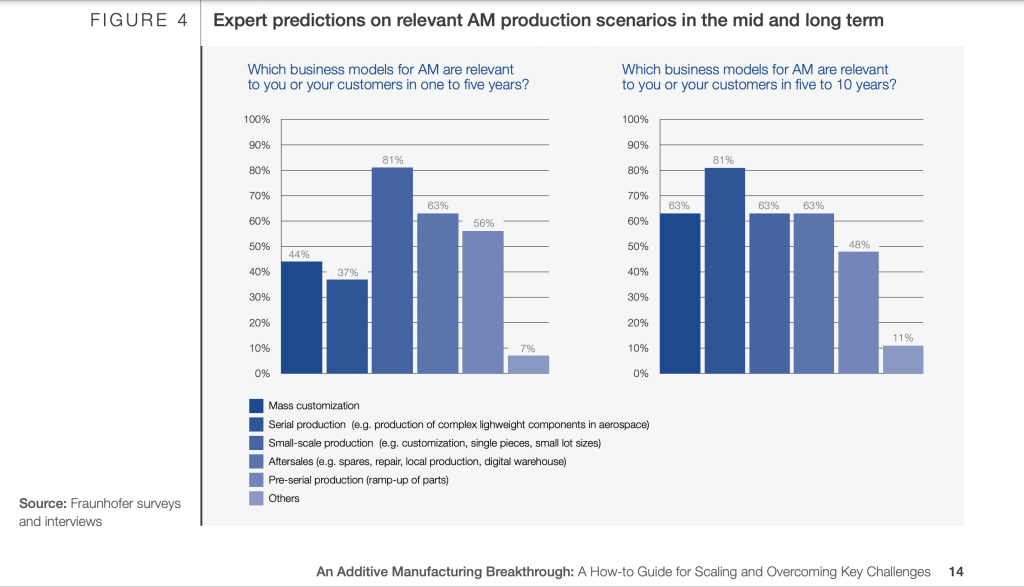

“By following the proposed call to action presented in our paper, a major leap in industrializing AM can be jointly developed from within the AM ecosystem,” reads the WEF’s paper. “With these changes, future business models and many new applications will be feasible in the next five to ten years, leading to a steady growth of the overall market, and offering disruptive potential for some industries.”

AM at the World Economic Forum

Given its self-prescribed role as independent chair of a global summit, designed to encourage cooperation between public and private firms of all shapes and sizes, the World Economic Forum has a lot of ground to cover when it hosts the world’s business leaders in Davos each year, so unsurprisingly, much of what’s discussed isn’t directly related to 3D printing.

However, when discussions at the event do delve into the obstacles facing advanced technologies, they sometimes provide an insight into the world of additive manufacturing as well. At the WEF two years ago, for instance, the organization issued a ‘Guide for 3D Printing’s Decision Makers’ and questioned the impact a digital border tax would have on the technology’s wider adoption.

Similarly, ahead of the 2022 edition of its Swiss summit, which will run from 22-26 May, the WEF has now offered an updated assessment of the current state of affairs in the 3D printing sector. Only this time, the group has partnered with ETH Zurich and the Fraunhofer IGCV, IPT and IAPT institutes, to uncover what it calls “the real story of AM,” by speaking directly with manufacturing leaders around the world.

In doing so, the organization says that it has been able to “move away from the hype” that surrounds the technology, and “define a new return on investment (ROI)-based narrative” for its industrial application. Taking the form of a seven-point call to action, this narrative is designed to help the industry’s leaders better drive 3D printing’s adoption, while placing an onus on greater cross-sector collaboration.

Planning a ‘major leap’ in adoption

Over the course of its latest state-of-3D printing analysis, the WEF interviewed experts from many of the industry’s biggest firms, including system manufacturers EOS, Stratasys and HP, as well as certification firms like DNV-GL and TÜV SÜD, and adopters ranging from Deutsche Bahn to PrintCity Manchester.

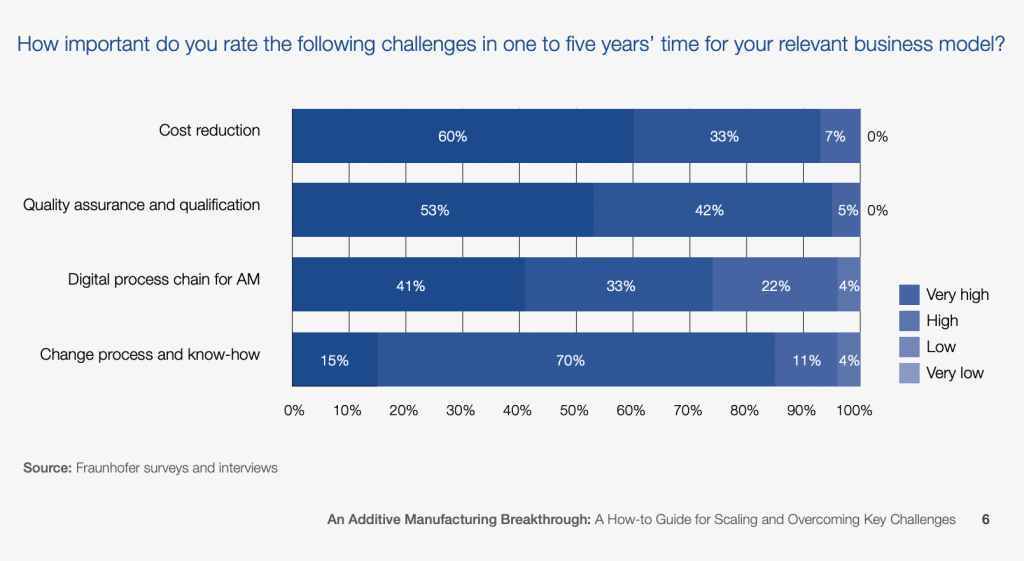

Interestingly, based on this series of interviews and case studies, the organization found that despite the continuing maturation of 3D printing, it still faces roadblocks to mass-adoption on multiple levels. When it comes to the technology itself, the study’s results showed that process predictability, material availability, post-processing and certification are the biggest limitations putting off potential users.

On an organizational level, the body also identified a “lack of clear AM adoption strategy” at many firms, with a scarcity in customer training and ROI calculation tools highlighted as particularly problematic. Likewise, when it comes to the wider world, the report found that a lack of standardization continues to alienate potential adopters, with integrated digital process chains remaining elusive in many areas.

To overcome the majority of these issues, the WEF has come up with four practical recommendations as well as seven calls to action. In the former, the organization suggests that manufacturers should help clients learn iteratively rather than going ‘all-in’ straight away, and encourage them to collaborate with third parties on projects, while focusing specifically on attractive “cost-benefit ratio” applications.

In order to turn these suggestions into actions, that “carry the industrialization of AM a significant step forward,” the WEF adds that a concerted effort needs to be made to simplify the technology’s qualification process, drive down the cost of applying it within serial production and better market its circularity benefits.

The group’s study also concludes that more needs to be done to digitize the process chain and educate engineers in commercial settings, while it calls for governments to up their funding into related research too. If all this can be accomplished, the WEF anticipates that 3D printing can allow users to achieve a quicker ROI, leading to its wider application, particularly as an in-sourcing tool.

“Depending on advances within the AM ecosystem, production could shift towards fully integrated industrialization,” concludes the WEF paper. “Most experts do not expect disruptive developments in the near term, but rather foresee a slow and steady development. Consequently, a possible breakthrough for serial production and mass customization within five to 10 years is foreseeable.”

The World Economic Forum’s full white paper titled “An Additive Manufacturing Breakthrough: A How-to Guide for Scaling and Overcoming Key Challenges” can be accessed here.

3D printing’s repeated calls to action

Within the 3D printing industry, it has become common practice for firms and organizations to commission internal research projects, with the aim of identifying a means of broadening the technology’s adoption. Just last year, Protolabs published the results of its ‘Decision Time’ survey, which revealed that 83% of oil and gas firms are weighing up adopting on-demand manufacturing for spare part production.

Inkjet technology developer Xaar has also released a white paper recently, indicating how its Ultra High Viscosity Technology can be used to unlock new 3D printing applications. Using in-house analysis, the company highlighted how the ability of its printheads to deposit fluids with viscosities of around 100 centipoises, is now taking the inkjet 3D printing and coating of parts to a ‘whole new level.’

Away from the self-serving reports generated by manufacturers themselves, certification firms such as TÜV SÜD continue to publish guidance as well, with the goal of improving 3D printing’s standardization. In October 2021, the organization published a paper of its own, which included a medical 3D printing guide, designed to condense a myriad of regulations into a more digestible format.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a World Economic Forum meeting space. Image via Unsplash/Evangeline Shaw.