The Seoul International Dental Exhibition and Scientific Congress 2015 (SIDEX2015) was held recently at the COEX exhibition hall in downtown Seoul, South Korea. The show encompassed over 275 companies from 14 different nations, with around 1000 booths set up. For those of you who are not familiar with the dental exhibition, the SIDEX show boasts a history of more than twelve years, and mainly deals with dental equipment and cutting-edge technology in related medical sectors, along with an international academic conference. Organized by the Seoul Dental Association, the show covered 19,000m2 of the 3rd floor lobby, as well as exhibition halls C and D and various meeting rooms.

Since I am not a dentist, and my gums and teeth are relatively healthy, readers might wonder why I would be there, loitering around the show. I went, of course, because I had heard that some 3D printers would be there as examples of the leading tech in new dental equipment. In total, I found five different 3D printers.

The first I encountered was DENTIS, a company that develops and provides a wide range of specialized medical equipment and high level services, including dental implants and specialized LED lighting for operating and surgical procedures. They told me that they decided to develop their own 3D printer, rather than buy someone else’s, because many of the printers available are too expensive and others have serious quality problems. So, they built a printer that is specialized for the dental sector and were selling it at what they thought was a reasonable price. Their printer is called the ZENITH, an SLA design that uses a blue laser to cure the liquid resin. The machine itself is about 340 x 350 x 490cm, with a build area of 125 x 125 x 160cm, a maximum resolution of 50um, comes with its own slicer program, and costs about $20,000USD. To an industrial user that might be a good deal…to me? Ouch!

The second I found was Hephzibah Co., Ltd, a company that has been specializing in industrial machinery as a manufacturer since 1986. They launched a new 3D printer called the Veltz3D Miicraft for dental purposes, even though on their website it states that it is intended for “jewelry industries”. Their entire line can be found at http://www.veltz3d.com/ although the site is mostly in Korean.

Kang YoungHo , a medical instruments developer that I met at the show told me that CAD/CAM and 3D printers are both useful in manufacturing dental models, but, for now, they have rather separate roles. As 3D printing continues to develop, they both will become major tech in the medical fields. And there is always a chance that, slowly, what CAD/CAM used to do could be replaced by 3D printers entirely.

The third company was Cybermed Inc., a leader in the 3D medical imagining software field that was founded in 1998. Their representative software packages were V-WORKS and OnDemend3D. Recently, they have focused on digitizing the dental industry. They also provide a customizable digital workflow solution called ON3Dlab that offers state-of-the-art dental design and manufacturing techniques, from digital impressions, CAD/CAM designs, 3D printing and milling services. Cybermed Inc. was also there with 3D printers from EnvisionTec. They explained that the two main areas of use are prosthetics and orthodontics, starting from scanning, moving to virtual design, and ending with manufacturing devices, tooth restoration, and orthographic applications, so they can now offer an entire range of solutions to their customers.

On a different note, it was pointed out that another benefit that 3D printers bring to the dental industry is that once patients are treated in Korea, the dental clinics have an obligation to keep the models made for 2~3 years, which means that in big hospitals, a good deal of storage is needed to keep those models. However, the 3D printer makes such a waste of room unnecessary. Those models can now be kept in digital form and printed out on demand. A seemingly small issue, unless you are a hospital administrator.

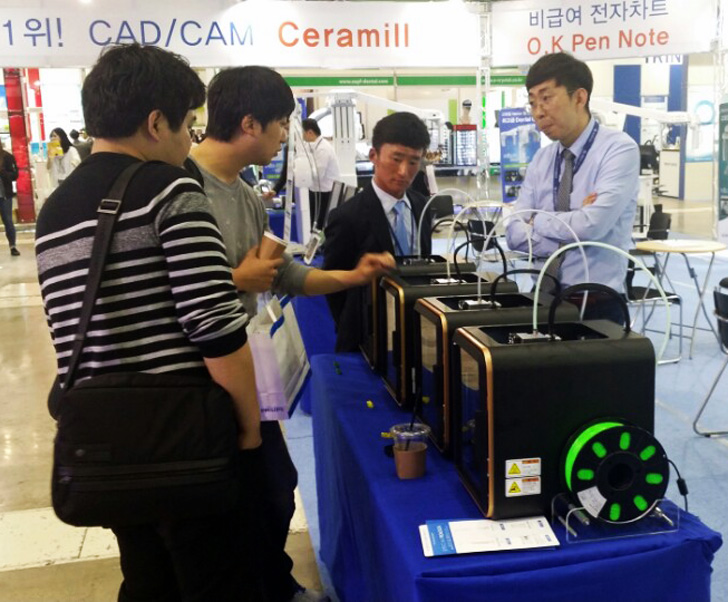

Next I met the people at PointNix, a dental/medical high-tech equipment developer and seller. Having a rather large booth right at the center of the venue, they had a wide range of equipment for inspection, including 3D printers from Moment. They had the new MomentS, which was launched in April. I haven’t had a chance to review the machine yet, so I was pretty excited to see it for the first time. Compared to the first Moment, the new printer is lighter and smaller, but with the same sized build area. I also noticed that they had drastically reduced the noise of the machine.

The CEO of Moment, Park Heewan, was also there and he told me that Moment is penetrating into the Korean domestic market rapidly with their new distributing partner, Chungmac Electronics, as well as continuing to grow in the Asian market overall. They now export to Japan, Australia, Turkey, Brunei, Kuwait, Malaysia, Singapore, Indonesia, and Hong Kong. They also plan to attend a trade show in the US and China later this year, to launch their new product into those markets. He also cautiously told me that his company appears to have become the top Korean 3D printer manufacturer last month, based on the number of units sold. He was also very excited to let me know that Moment was invited to become part of Samsung’s “SamsungDreamTalk“, an educational program organized by Samsung Electronics to help youngsters map out their future career paths and experience new jobs. It was initialized in 2012 and each year has involved about 20,000 youngsters. Moment’s role in the program is to introduce 3D printing to the festival.

The last company at the show was one of Stratasys Korea’s authorized dealers, Medicodi, Inc. In addition to being a Stratasys reseller, they are also a reseller for Carestream Dental, and sell CT machines for dental and digital X-ray systems. At this show they presented two high-end 3D printers, the Object 260 and the Object 30 orthodesk which were on full display and were, as always, very impressive. Stratasys has been doing quite a lot in Korea, mostly through its vigorous reseller programs, to spread the technology and its uses and this show was further evidence of that commitment.

All in all, this show demonstrated that 3D printing is beginning to take a bigger part in many diverse business sectors, and that as time goes by, it will likely continue to spread. Now is a good time to catch up with the technology, as it is likely to be entering your business world…eventually.