As Tony Fish, FabLab London’s co-founder, explained me when I visited the space opened last September, there are now some 30 makerspaces in the UK’s capital and each brings its own very specific expertise to the table of personal, digital fabrication. The same is true of all FabLabs throughout the world. The FabLab London’s specialty, which is in line with Tony’s background, is to focus on extremely affordable, self assembled, open source digital manufacturing tools to hack just about anything solid.

“You can now get a Printrbot 3D printer for £500, which is what we just offered in our latest workshop,” Tony says “and we have built CNC machines and laser cutters for around £100. We, as a FabLab, can give our member access to some £100,000 worth of digital fabrication machines which means there are no more limits to creativity. It used to be that you could only experiment with open source software, now hardware is no longer off limits.”

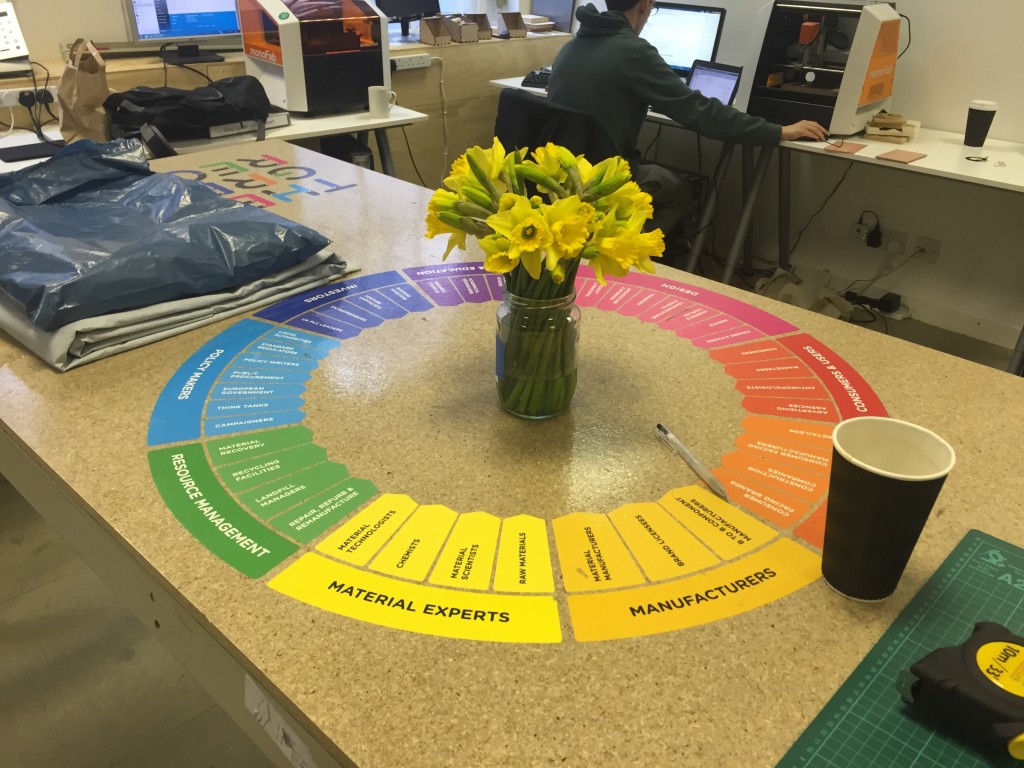

Launched in February 2014, the Fab Lab London is the City’s first purpose built digital fabrication and rapid prototyping workspace. It is located inside a beautiful 4000 square feet space at 1 Frederick’s Place, together with founding partners Bathtub2Boardroom and the RSA Great Recovery initiative. The lab was founded by Tony, an investor, entrepreneur and author with a background in electronics, computing and design, and Ande Gregson, a “creative technologist”, exploring the intersection of science, arts and technology”.

To help sustain itself it provides open and membership based access to digital fabrication tools, an electronics lab, education workshops, making events directed at a vibrant community. It also partners with several companies offering digital fabrication and later thinking consultancy services.

“We help individuals and companies learn about the application of digital technologies, rapid hardware prototyping, 3D printing and sustainable design practices,” Tony says. They do this through a range of fabrication platforms and tools which include 2 laser cutters, 7 3D printers, 2 CNC milling machines, 3D scanners, traditional hand tools (saws, drills, hammers, chisels etc) and even a digital knitting machine.

Tony is absolutely enthusiastic about the possibilities that digital manufacturing, especially the combinations between different technologies, can offer and his passion is contagious. He sees every single object around us as something that can be modeled, changed, improved and personalized. A bit like in the movie Matrix: his computing background makes him view reality as something that can finally be really modified. He sees all personal fabrication tools – including a digital knitting system – as what makes this possible.

Sharing his vision and passion with the FabLab’s members, the children in particular (“They have time to learn”, he explains), he wants people to come and learn how to make things, both for themselves and to understand the value that exists behind self fabricated products. “Since our opening we have had some 7,000 people come through the lab, aged 8 to 80,” he tells me.

The philosophy that Tony bases his work on is that of “Learn, Make, Share” and that he explains, is what the most productive people do throughout their lives. “They spend a third of their life learning, one third making and one third sharing. Incidentally – he adds – that is also what we do through an ideal day or week period”.

Tony feels that doing something with their hands can have a deep psychological impact on all humans. It is also called the “Ikea Effect”, that is the reason why we like so much more a piece of furniture that we put together ourselves. It is the essence of personal fabrication, the number one guarantee that hardware hacking and local manufacturing are not going away anytime soon.