Israeli pharmaceutical firm Syqe Medical has employed the expertise of 3D printer and materials manufacturer XJet for the manufacture of high-precision, heat resistant ceramic parts for the medical sector.

Syqe has installed XJet’s Carmel 1400 additive manufacturing system, which features the company’s patented NanoParticle Jetting (NPJ) technology, to enable the production of ceramic parts through inkjet printing.

“Syqe Medical is making life-changing advancements in the field of patient care so we’re delighted to see them reaping the rewards of XJet’s unique capabilities,” said Dror Danai, XJet CBO. “Ceramics have some very valuable material properties, but it can be difficult to exploit them due to difficulties in the manufacturing process.

“XJet delivers all the benefits of ceramic materials, with accuracy and precision, but without the difficulties of traditional manufacturing.”

Syqe Medical in 3D printing

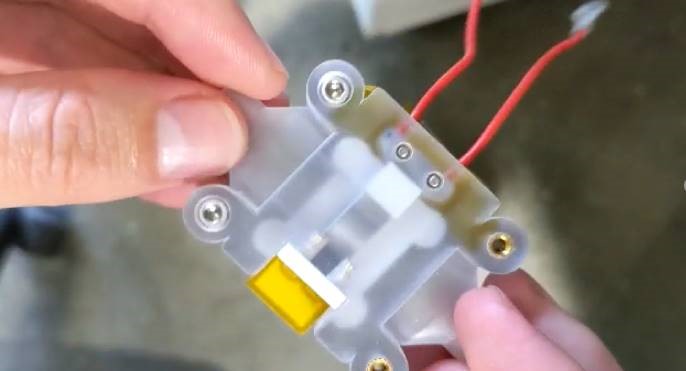

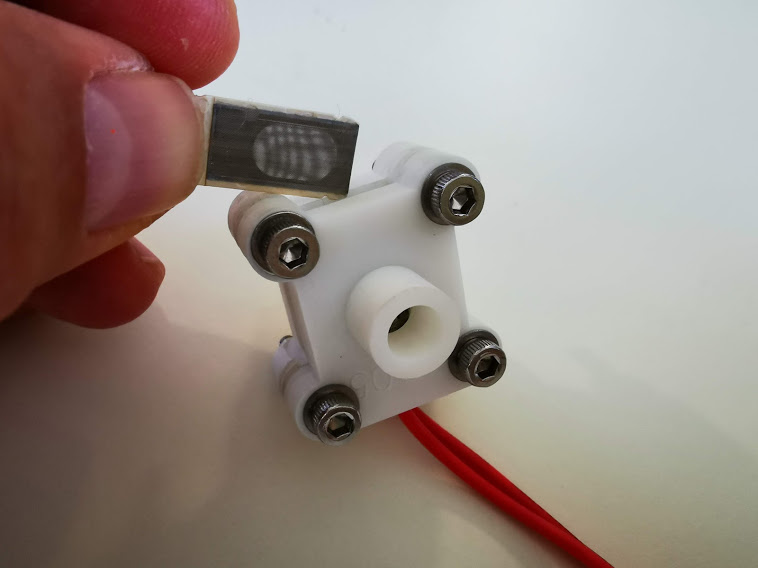

Syqe Medical is the manufacturer of a novel Selective-Dose inhaler which enables the precise delivery of a range of therapeutic drugs to patients, based on their symptom relief requirements. First brought to market for use with medical cannabis, the technology now allows hundreds of existing and preclinical drug molecules to be considered for inhalation. The device aims to increase the effectiveness of patient treatment, helping to create optimum balance between symptom relief and adverse effects.

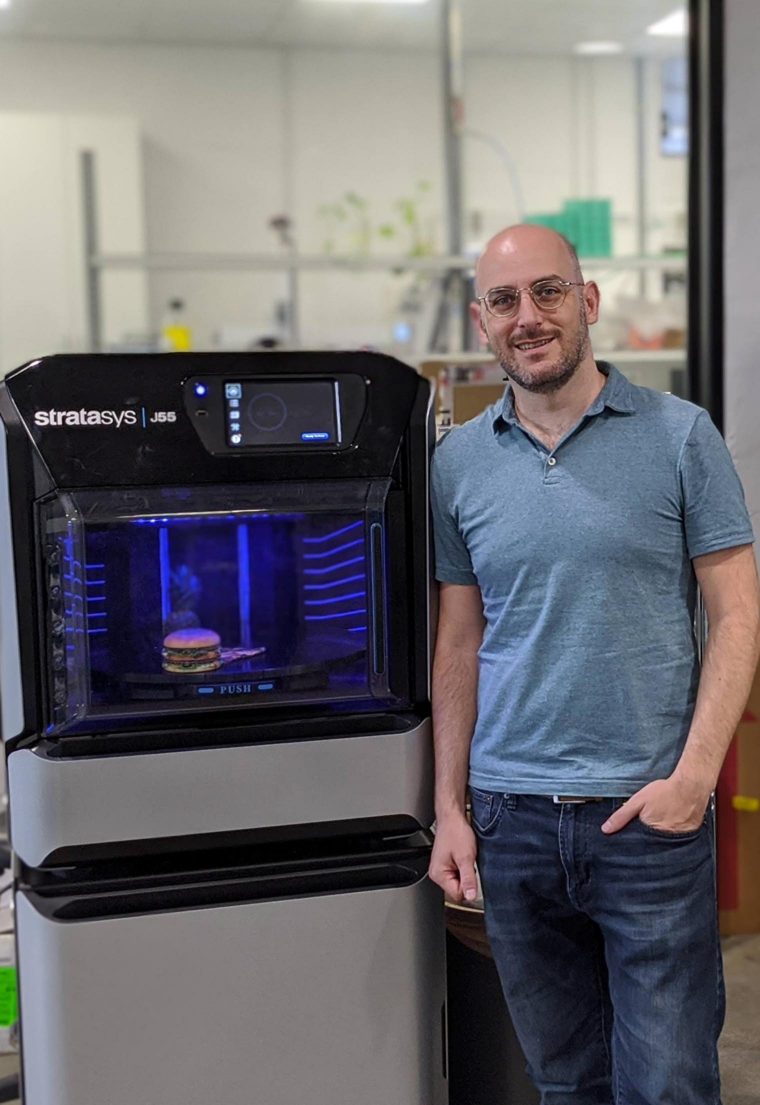

Syqe is no stranger to utilizing 3D printing, having just last month invested in a Stratasys J55 3D printer, which launched in April, to produce ultra-realistic prototypes of the inhalers. Utilizing Stratasys’ technology, the Syqe team began 3D printing the chassis, casing, and springs for the inhaler prototypes, which will be validated for fit, form, and function before progressing to medical trials.

The XJet Carmel 1400 additive manufacturing system

Before turning to XJet, Syqe had investigated PEEK materials and traditional manufacturing methods for its product development process, largely due to heat resistance requirements. However, during testing the firm found constraints within the design processes, which required multiple adjustments, as well as high production costs, long delivery times, and questions over material durability.

“Realising we needed another solution, we turned to XJet,” said Itay Kurgan, product manager at Syqe Medical. “We have a wealth of experience with additive manufacturing technologies and whilst the polymer materials don’t have the heat resistance we need, XJet ceramic materials are resistant to temperatures even higher than our requirements, and of course they are electrically insulated.”

XJet’s Carmel 1400 additive manufacturing system fabricates ceramic parts from ultrafine layers via its NPJ process. The parts produced feature superfine details, smooth surfaces, and are highly accurate, all of which can be preserved by easy-to-wash-away soluble support material.

“Minor design adjustments are very easy, and results are precise and repeatable, so we can achieve optimum accuracy and delivery times are very fast,” added Kurgan. “Where all other options were flawed in at least one aspect, XJet provided the perfect solution.”

XJet updated its ceramic additive manufacturing system, the Carmel 1400C, at Formnext last year, changing the branding of its original Carmel 1400 system to distinguish which platforms can process ceramic (C) or metals (M). Shortly after, the firm installed a Carmel 1400C at Katholieke Universiteit Leuven (KU Leuven) in Belgium, becoming the first XJet system to be implemented at an academic institution within Europe.

Most recently, XJet announced a global partnership with dentistry leader Straumann to advance the capabilities of its 3D printing technology for dentistry applications. The partnership will see the XJet Carmel 1400 system currently in use at the Straumann headquarters in Basel, Switzerland, begin producing end-use ceramic parts.

3D printing ceramics for the medical sector

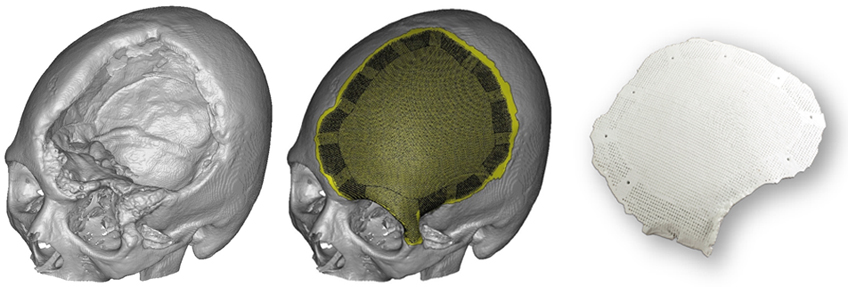

Recent developments in materials science and additive manufacturing technologies have allowed the medical sector to make use of advanced ceramics for a variety of applications.

In 2018, researchers at Vilnius University in Lithuania succeeded in 3D printing glass-ceramics on a nanoscopic scale, unlocking new potential in microdevice manufacturing, such as microrobots or microfluidic chips used in medical research.

Earlier this year, ceramics expert 3DCERAM-SINTO announced plans to advance its ceramics 3D printing technology to develop the next generation of medical X-ray imaging systems, while 3D printer manufacturer Admatec revealed that medical and dental professionals can now use CAM Bioceramics’ medical grade ceramic materials with Admaflex DLP 3D printing systems, certified to ISO 13485:2016.

Most recently, the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS) developed a Multi-Material Jetting (MMJ) system to combine numerous materials, including ceramics and metals, into a single additively manufactured part with various properties. The technology has potential applications in the aerospace, consumer products, and medical sectors, among others.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows XJet ceramic materials deliver the high temperature resistance and electrical insulation needed for Syqe Medical’s new test facility. Image via XJet.