In this edition of Sliced, the 3D Printing Industry news digest, we cover the most recent business developments, partnerships, and innovations across our industry.

Today’s edition features new 3D printers and materials, additive manufacturing partnerships, footwear and eyewear applications, certifications, funding rounds, and a 3D printed vocal mask for choirs.

Read on for the latest updates from 3DGBIRE, CRP USA, YOFACE, Alloyed, Tinkerine, Mouser Electronics, Riot Ventures, and more.

3D printer launches, shipments, and investments

Kicking off the latest 3D printer news is 3D printing start-up Fortify, which has recently started shipping FLUX ONE printers to its customers’ sites after initially launching the printing platform in March. FLUX ONE users can print fiber-reinforced photopolymer mold tools in a matter of days, with the printer incorporating the firm’s Fluxprint and Continuous Kinetic Mixing (CKM) proprietary technologies.

“Shipping our first product is a monumental step for fortify,” said Josh Martin, CEO and co-founder of Fortify. “Despite shutdowns due to Covid, our lean team has been able to push forward and deliver the technology with minimal disruption to our timeline. After several years of development and servicing customers remotely, we are thrilled to have customers using these machines at their site to bring products to market.”

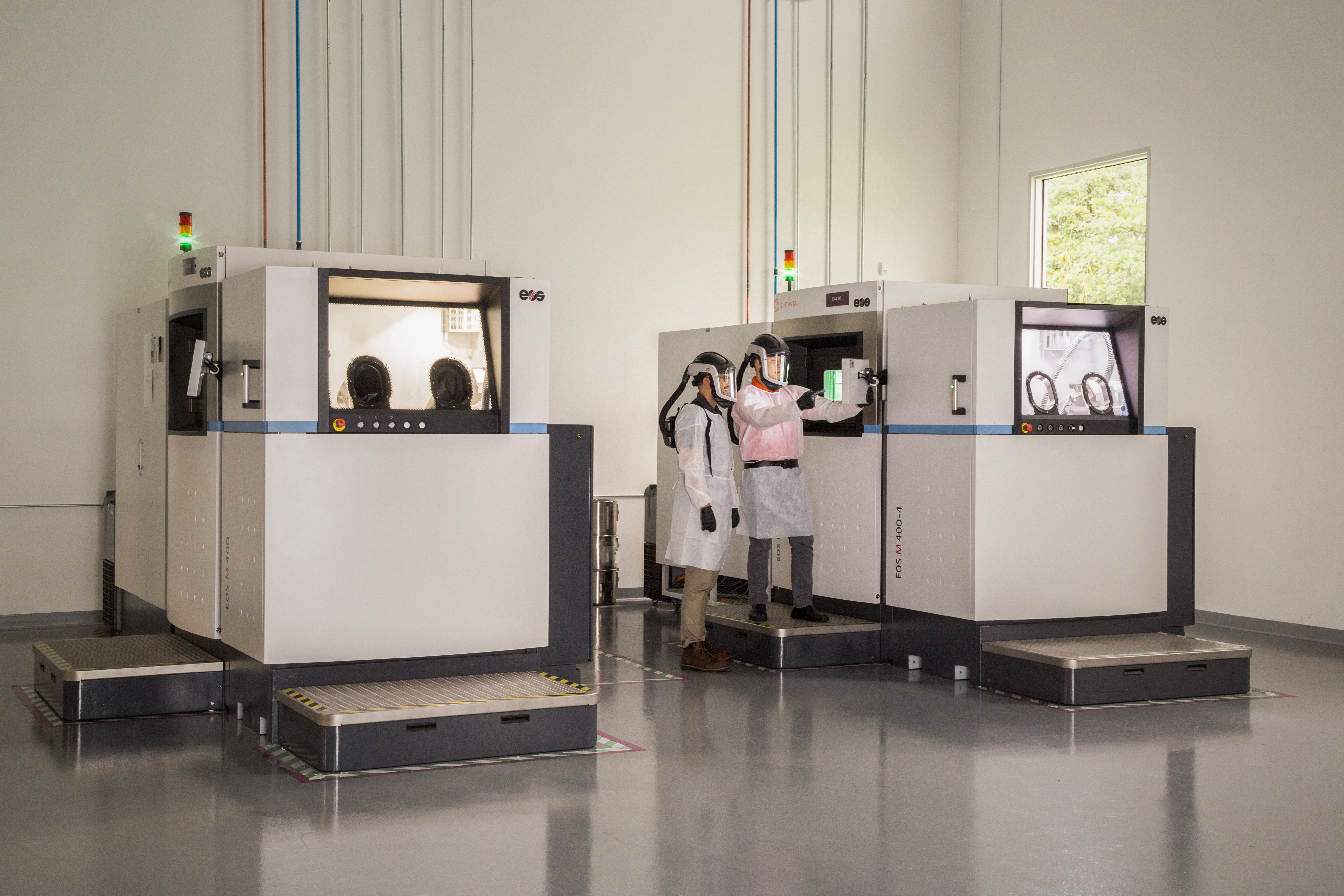

Meanwhile, Florida-based metal 3D printing service Sintavia has acquired two additional M400-4 quad laser printers from LB-PBF systems leader, EOS. Delivered in September, the new additions increase the number of M400 printers operated by Sintavia to eight. Looking forwards, the firm expects to add a further six to eight industrial printers to its operations by the end of 2021.

“The global pandemic has turned the traditional aerospace supply chain on its head, creating real opportunities for companies like Sintavia to offer high precision solutions to OEMs worldwide,” said Brian Neff, Sintavia’s CEO. “The EOS M400-4 is the workhorse of our factory, and we continue to see great results with it.”

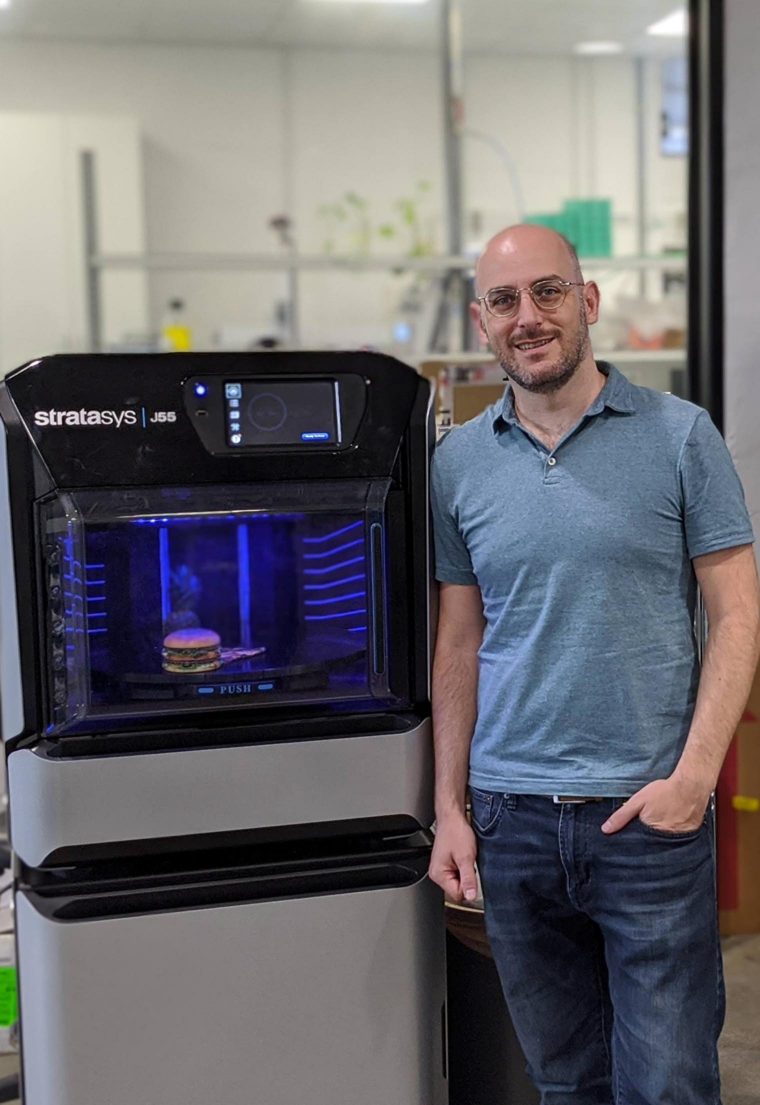

Elsewhere, Israeli pharmaceutical firm Syqe Medical has invested in Stratasys‘ J55 3D printer, launched in April, to produce ultra-realistic prototypes of inhalers. Utilizing the J55’s full-color and multi-material offering, the Syqe Medical team has set to work 3D printing the chassis, casing, and springs for the inhaler prototypes, which can then be validated for fit, form, and function before progressing to medical trials.

“Our products include very precise and intricate airways, which are usually less than 1mm in diameter,” said Itay Kurgan, product development manager at Syqe. “Achieving this level of complexity in the design of a prototype is very difficult, but the J55 allows us to incorporate such intricate structures into the design with a level of accuracy we’ve not seen before.”

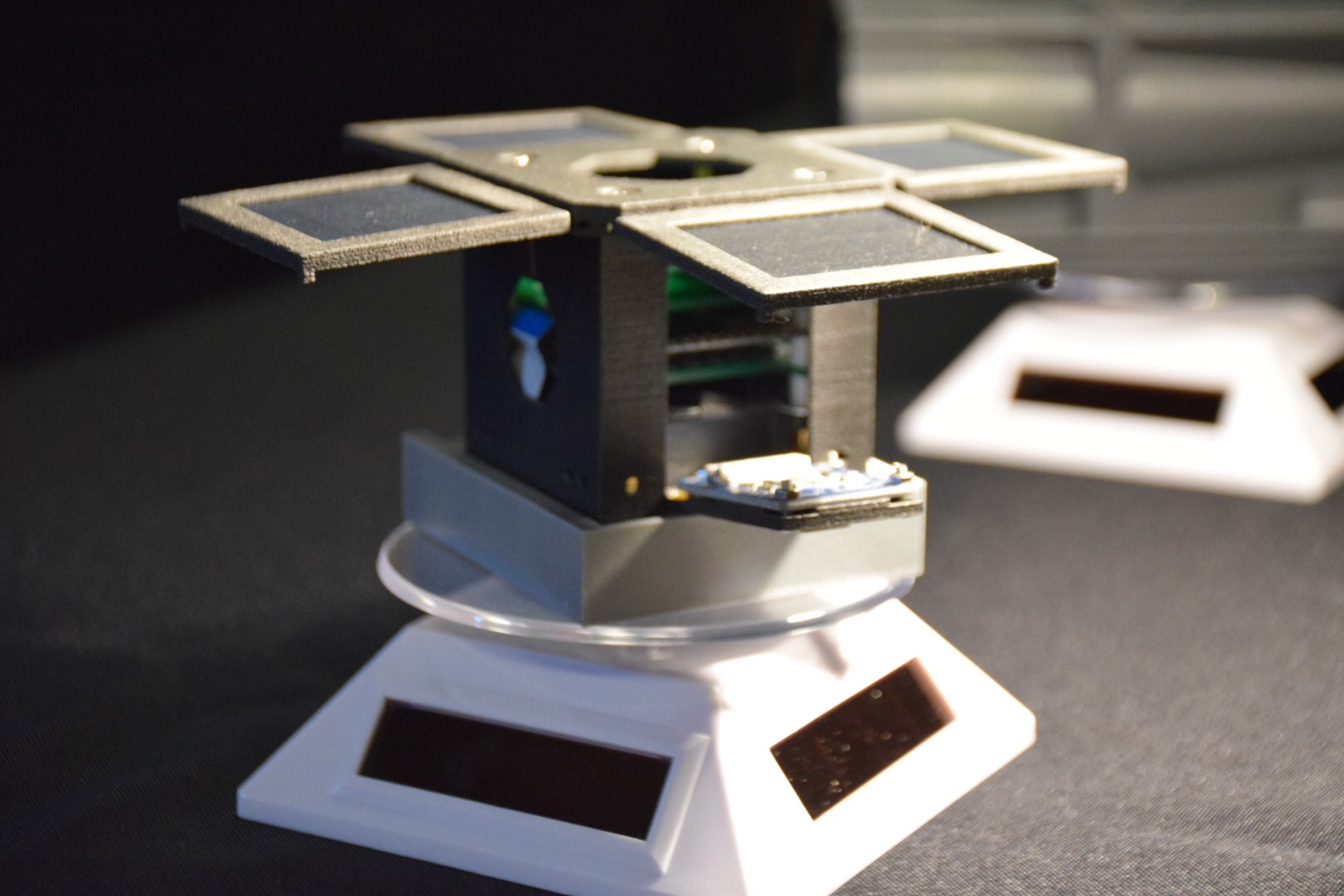

Aerospace certification for CRP USA

3D printing services and materials provider CRP USA has received AS9100 Rev. D certification for the manufacture of 3D printed aerospace products. AS9100 Rev. D is the most recent version of the AS9100 international Quality Management System standard for the Aviation, Space and Defense (AS&D) industry.

“We have taken our expertise in additive manufacturing solutions to new heights to produce parts for the most demanding sectors as Aerospace and Defense,” said Stewart Davis, director of operations at CRP USA. “AS9100 Rev. D certification reflects our dedication to achieving the highest standard of customer satisfaction; moreover, it is a further demonstration of the effectiveness of additive manufacturing and use of Windform as structural materials for space and aerospace applications.”

Originally developed for the motorsports industry, CRP’s Windform materials have been used increasingly in aerospace and space exploration applications in recent years, with the AS9100 certification indicating the firm’s ongoing commitment to these sectors.

3D printing partnerships for Alloyed, Mouser, Tinkerine, and Prototal

Oxford-based 3D printing alloy specialist, Alloyed, has signed a Memorandum of Understanding (MoU) with Japanese additive manufacturing service provider NTT DATA XAM TECHNOLOGIES (XAM). The collaboration will see the companies combine their areas of expertise in metal 3D printable materials and 3D printing processes to deliver fine-featured additive manufactured products to the Japanese market.

Since announcing the release of it what it deemed the world’s first public high-temperature nickel alloy designed from the bottom-up, the ABD-900AM, Alloyed has been seeking further opportunities in the Japanese market. In January, the firm completed a £10.7m equity funding round in which JX Mining and Metals of Japan was a major investor.

Elsewhere, electrical component distributor Mouser Electronics has agreed a global distribution agreement with intelligent motion specialist Trinamic to stock a broad range of products, including stepper motor drives and evaluation kits.

In addition to Trinamic’s TMCM-3110 3-axis stepper motor driver and TMCM-6100 6-axis stepper motor controller, Mouser will also stock its TMC5130-EVAL-KIT. The evaluation kit enables engineers to explore all options of the Trinamic’s TMC5130A cDriver integrated motor driver and motion controller for 3D printing and other automated applications.

Switching focus to Personal Protective Equipment (PPE), Canadian 3D printer manufacturer Tinkerine has partnered with Vancouver International Airport (YVR) and Wavefront Center for Communication Accessibility to design and manufacture clear face masks.

Equipped with a replaceable filter cartridge, the face masks will be reusable, with the clear design removing communication barriers to communication for those who are deaf or hard of hearing. The masks are available for bulk purchase for YVR and communities in need, and for every face mask sold, YVR will donate another to a vulnerable community.

“The global pandemic has challenged all of us to approach things a little differently,” said Tinkerine CEO Eugene Suyu. “Providing accessibility to communication is now more important than ever in a time where face coverings are a norm.”

Rounding off this week’s 3D printing partnership news, polymer additive manufacturing specialist Prototal Industries has acquired 3T Additive Manufacturing Polymers (3T AMP), its first acquisition outside its Nordics territory and an indication the firm is looking to extend its reach throughout Europe.

Boasting several high-quality certifications for aerospace and medical, 3T AMP has one of the largest capacities in Europe for polymer 3D printing.

“Additive manufacturing has been a market constantly growing and innovating, and Prototal has made a number of acquisitions to consolidate its position and expand its offering,” said Jan Löfving, CEO of Prototal, and CSO Henrik Lundell. “3T AMP has been at the forefront of this market for over twenty years, is a great fit for our family of brands, and will benefit all customers. It is also a strong signal to the market of Prototal’s intention to actively develop the polymer market in the UK and globally.”

New 3D printing applications for eyewear and footwear

HP Senior Executive Edward Ponomarev showed off the company’s latest prototype 3D printed running shoes in a recent LinkedIn post, having tested them out on a 5km run.

The shoe was designed through HP’s Fitstation using 3D scanning and printing technology, and according to Ponomarev is the first functional running shoe with 3D printed parts via Multi Jet Fusion (MJF). Through Fitstation, a scan is taken of an individual’s foot to create a 3D digital model, which is then sent to a HP 3D printer to create a customized insole. Ponomarev’s running shoe weighed less than 200g, featuring lightweight uppers and ‘great energy return’.

Moving onto eyewear, Brazilian fashion brand YOFACE has produced what it claims are the first glasses printed with 3D printing technology by a Brazilian company. The glasses are 3D printed with nylon powder to produce lighter, more resistant frames that are comfortable over prolonged periods of use.

Founded by businessman Ivan Cavilha, YOFACE aims to produce clothing and accessories for the fashion market through a combination of technology and sustainability. Any surplus nylon from the 3D printing process during the production of the glasses is reused.

Riot Ventures aims to raise $75 million

Venice-based ‘hard tech’ investor Riot Ventures Management has filed for a $75 million fund, a notable increase from the company’s first funding round in 2017 which raised $10 million.

Riot Ventures invests mainly in robotics and artificial intelligence (AI) products and platforms. One of its more high-profile investments is that in 3D printing firm Desktop Metal which recently announced its intention to go public, a move which will see it listed on the NYSE with the ticker symbol “DM” and achieve an estimated equity valuation of $2.5 billion.

New developments in 3D printing materials

South Dakota-based 3D printer and materials manufacturer B9Creations has launched its new FastWax Castable resin, which reduces post-processing and polishing processes due to its smooth wax-like finish. The FastWax material is the latest in the firm’s castable materials line which includes Emerald and Yellow resins.

The FastWax resin is aimed primarily at the jewelry sector, enabling jewelers to 3D print intricate features such as rings, shanks, and settings which traditionally required molds, while providing a smooth finish.

“Jewelers have always been one of our most valuable customers – and sources of insight,” said Shon Anderson, B9Creations’ CEO. “While we’ve gotten great feedback on our Emerald and Yellow castable resins since their launch, we’ve continually heard from jewelers asking for ways to streamline their workflow, cut down on post-processing, and enable them with quicker turnaround to serve their customers better and faster than ever before. That’s why we developed FastWax.”

Meanwhile, additive manufacturing service and training provider 3DGBIRE has announced the addition of AquaSys filaments to its material portfolio. 3DGBIRE will distribute newly patented composite material, AquaSys 120, throughout the U.K. and Ireland to offer 3D print technicians a temperature-resistant, water-soluble support material alternative.

“We are delighted to bring AquaSys 120 to the UK as part of an exciting and expanding filament portfolio,” said Leah Melling, sales and marketing manager at 3DGBIRE. “The world’s first tap water soluble support material that works with a wide variety of engineering thermoplastics, dissolves rapidly in tap water up to six times faster than PVA, and is stable up to 120 degrees celsius build chamber temperature.”

Part of Infinite Material Solutions, AquaSys is the latest firm to choose 3DGBIRE as its U.K. distribution partner, joining the likes of Kimya 3D filaments.

Vocal mask gets choirs singing again

Rounding off this week’s news is the development of a specialized PPE mask which enables individuals in choirs and music classes to sing unobstructed. Music teacher David Angerman came up with the idea, partnering with local 3D printing service provider Varia 3D to produce a vocal mask prototype.

The mask is constructed from a copolyester-based elastomer from specialty chemicals company Evonik, based on Structured Polymers‘ new powder production process acquired by the firm in 2019. Varia 3D and Evonik worked closely together during the development of The Vocal Mask.

“With Evonik’s new copolyester material, we were able to check all the boxes for The Vocal Mask production,” said Brian Bauman, founder of Varia 3D. “David needed the mask frame to be economically produced in a natural black flexible material with high compression and tear strength. We were able to meet this need eliminating risky tooling costs when launching a new product.”

The Vocal Mask is currently on sale from Varia 3D’s website, and has already been purchased by individuals, churches, universities, and public and private schools.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows HP Senior Executive Edward Ponomarev showing off the company’s latest prototype 3D printed running shoes in a recent LinkedIn post, with the SLICED logo.