Japanese company Super Inkjet Technology (SIJT) Inc. have created a desktop printer that can print metal in sub-micro sized particles. Established in 2005 following work from a research institution, this “super fine inkjet” technology has particular importance for the printing of electronics. Research was carried out by the National Institute of Advance Industrial Science and Technology (AIST) and the Japanese team is led by CEO and founder Kazuhiro Murata. 3DPI spoke to Neil Chilton, Technical Director of Printed Electronics, SIJ Technology’s technical representatives in the UK and Europe to find out more.

According to the company, their method is unlike any of the current drop-on-demand (DOD) inkjet printing processes of Thermal DOD or Piezoelectric DOD. SIJ prints with much smaller droplet sizes using metals and conductive inks yet operates under normal temperatures and atmospheric conditions, rather than requiring a vacuum or high temperature build chamber.

Super Inkjet Technology

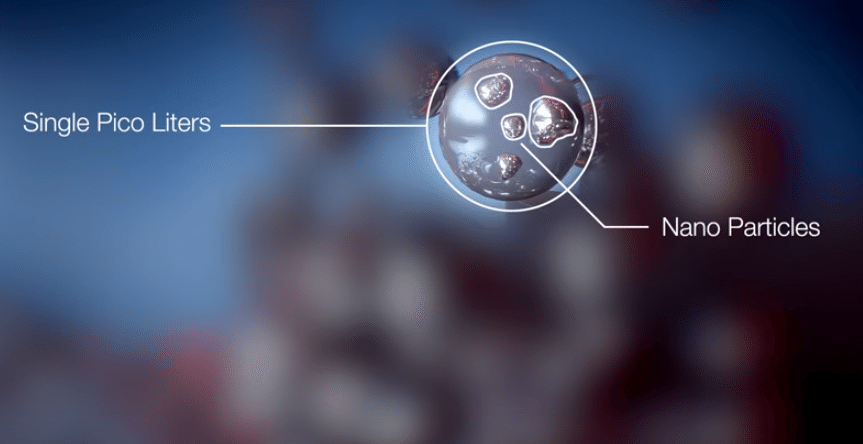

SIJ Technology allows for the printing of droplets that are sub-femtoliter in size, 1/10 smaller in size than a conventional printer and 1/1000 smaller in volume. Despite the machine using only a single nozzle to eject the particles, the use of nanoparticles appears similar to XJET’s nanoparticle jetting which has thousands of printing nozzles. Israeli company XJET have suggested their technology has application for use with ceramics and with metals. As of yet they have not demonstrated its potential for 3D printing electronics. Furthermore, the XJET is machine is quite dissimilar in size to SIJ’s small 64kg device.

The Printing Process

The printing process can be likened to snowballs being dropped on top of one another. When the ink is ejected it dries mid-air meaning the printed form is semi-solid. This allows the ink particles to be printed on top of one another to essentially create three-dimensional shapes. However, the company instead of using the term 3D printing prefer to refer to the technique as 2.5D. However, the technology does enable vertical printing. Nevertheless, objects printed with SIJ technology are required to be cured following their print.

Advantages of SIJ Technology

One advantage of the nanoparticle inks used by SIJ Technology is that the high temperatures that are often associated with metal printing are not required since the melting point of metal particles smaller in diameter than 20 nanometres dramatically decreases. For example, a micron sized silver particle has a melting point of 961°C while a nano sized particle may be as low as room temperature. This has obvious advantages for the technology as it allows the printing of these substances in room temperature conditions without having to factor in heat management, which is something we’ve seen recently with Thermwood. As a result of this, the Japanese company are able to house the technology within a small desktop machine without having to create an environment with high temperatures or vacuums.

Another major advantage of this technology is the lack of lasers and use of inkjet. This is, similarly, one of the advantages of XJET’s technology as it increases the speed of metal printing as well as the reliability. XJET market their nanoparticle jetting printer as being five times faster than laser metal additive manufacturers.

Applications of SIJ Technology

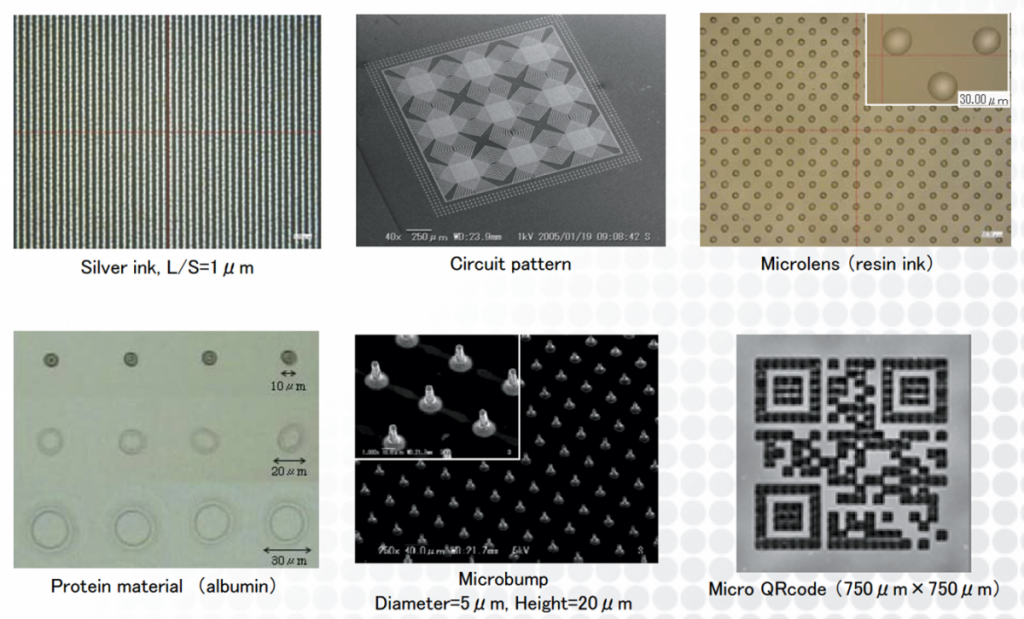

According to the Japanese team, applications of this technology are, as mentioned above, primarily involving electronics, such as printable electronics, solar cells, touch panels, and LEDs. While in addition, other possible applications according to the Japanese company involve optics technology and biotechnology. There are many SIJ systems in use across the world, in Europe and a number in the U.S. In the States they have printed micro-batteries using SIJ technology and the machines can be used for electronic system repairs. SIJ Technology Inc. will further showcase their printing capabilities next May at Printed Electronics Europe 2017 in Berlin.

3D printing electronics is an area where relatively few companies have ventured, however one enterprise 3DPI spoke with earlier this year is already showing signs of taking the lead and Nano Dimension also announced this week that they have delivered one of their 3D printers to a Fortune 100 company.

Featured image shows a 3D printed 2 layer PCB made using Nano Dimension’s Dragonfly 2020 3D printer. Photo by Michael Petch.