Oxfordshire in the UK isn’t exactly where one would expect a new trend to start, but this home 3D printed wedding cake topper selfie may just start the next big thing. No, not selfie wedding cake toppers, but small-scale home 3D printing businesses.

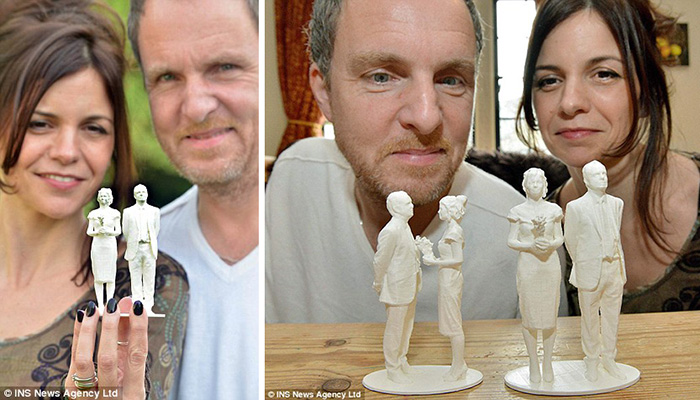

Emily and Carl Ogasthorp’s wedding has been the talk of the internet this week, as pictures of their selfie wedding cake topper went ‘a little’ viral. And it isn’t surprising when you see how well done and detailed the selfie actually is. Even more so when you consider it was scanned using a home built setup and printed on a home-assembled 3D printer.

“It was great. When it was on the cake everybody was like: ‘Oh, my God that is you?’ It was so instantly recognizable that it was us.” Said Emily.

“I haven’t seen anywhere in the UK doing cake toppers like this one. It caused quite a stir. I guess it is something a lot of people haven’t seen before.” Dey said. “There is an interest in 3D selfies. After doing my friends and their kids, other people have started asking for it.”

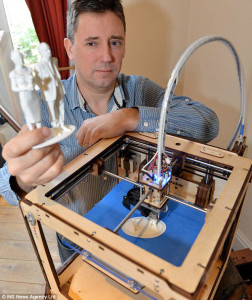

Mr Dey offered up use of his scanner and 3D printer to the couple as their wedding gift, but was so encouraged by the reaction to the cake topper that he’s started up his own 3D printing business. He calls his business ThinkSee3D and offers 3D modelling, scanning and printing.

He’s starting small, sticking to wedding cake toppers and selfies, but he’s also finding new ways to help his friends and community using 3D printing. When his friends lamp had a broken part, Dey scanned the broken screw and printed him a new one.

Small homegrown 3D print shops are the obvious first step to making 3D scanning and printing ubiquitous parts of our lives. While the large corporations and their lawyers debate, consider and hash out ways to deal with the growing ability to literally 3D print anything and what that means for copyright laws, small makers like Mr. Dey are getting started with the task of printing our future one broken lamp screw at a time.