In this edition of our 3D printing news digest Sliced, we feature: BAE Systems, Bloodhound SSC, Air Force Institute of Technology, Concept Laser, CRP Group, atum3D, ERM Fab & Test, Occipital, and KFC.

BAE Systems opens New Product and Process Development Center

British aerospace company, BAE Systems has opened a new facility in Samlesbury, Lancashire. The New Product and Process Development Centre (NPPDC) will house 3D printing and virtual reality technology to assist the design process for aerospace manufacturing. The company produced 2,500 3D printed parts last year, up 20% from the year prior and has recently conducted research into 3D printed feathers for their aircrafts.

To celebrate opening the facility, the Prince of Wales was invited on a tour and tested the VR design capabilities in the ‘VR Cave.’

Bloodhound SSC delayed

The much-anticipated British attempt at breaking the land-speed record has unfortunately been delayed due lack of funding. The supersonic Bloodhound car is developed by the British team and includes 3D printing technology support provided by Renishaw.

Speaking to the BBC, Bloodhound director Richard Noble said, “I’m reasonably happy now that we’ll be able to make our budget this year, which is great – and that means we will be on the desert, running the car, probably in mid-summer 2018.” The problem is not necessarily with gaining sponsorship, as the group has signed a number of deals including Chinese company Geely, with more deals currently in the pipeline. “The money is coming in but it doesn’t always match our planning and fit with the times when we need it,” explained Noble.

However, this does mean the group will have more time to ensure the rocket has sufficient power to break the record, even if the weight of the car is heavier than expected.

Air Force Institute of Technology acquires Concept Laser machine

The US Air Force Institute of Technology (AFIT) graduate school has announced the acquisition of a Concept Laser M2 Cusing machine. The machine will be shipped to them at Wright-Patterson Air Force Base in Ohio. The M2 Cusing is a metal 3D printer that will enable students to conduct research with key metals such as titanium, aluminium, and inconel.

The US Naval Research Laboratory has similarly employed an M2 Cusing machine from Concept Laser at their Washington base. This sale is the latest since U.S company GE purchased the European Concept Laser.

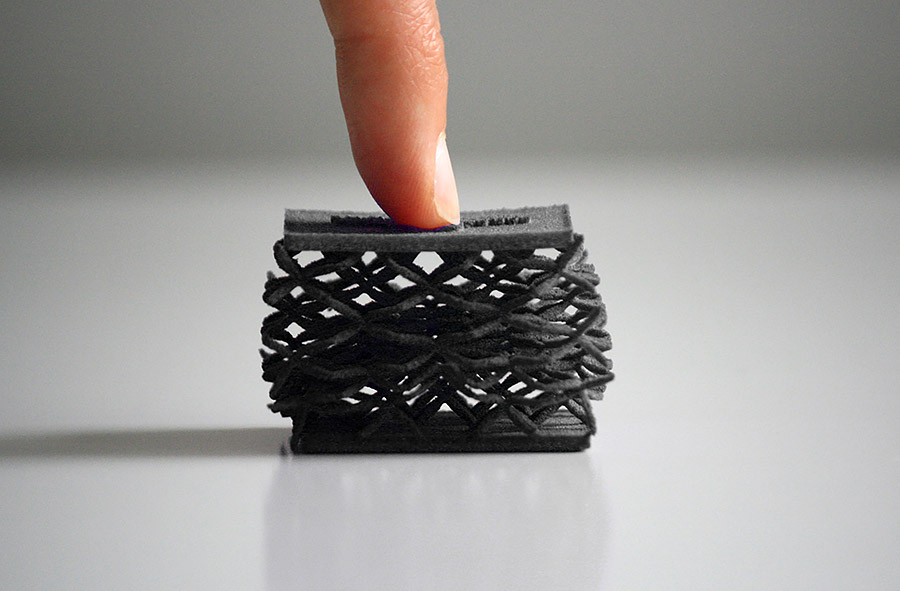

CRP Group launches Windform

Italian additive manufacturing automotive specialist, CRP Group, has launched Windform RL thermoplastic. The 3D printing material is the first thermoplastic the Group has produced using their material branch, Windform. The material is similar to rubber and has good shock absorbing qualities, the company believes it could be utilized to manufacture footwear.

atum3D partners with ERM Fab & Test

Dutch DLP printer manufacturers atum3D has announced a partnership with French manufacturing solutions company ERM Fab & Test. Cyril Liotard, founder of ERM spoke about the announcment, “With the atum3D DLP Station, we extend our existing portfolio with state-of-the-art DLP technology which brings previously inconceivable accuracy in a midrange machine.”

Occipital releases Skanect 1.9

San Francisco based company Occipital has announced an update to their scanning software Skanect. Skanect 1.9 now allows users to capture higher resolution images and provides higher details than the past version.

Occipital, as well as providing 3D scanning software, also develop scanning hardware. The company manufactures scanning attachments for iPads that can turn the mobile devices into fully fledged scanners.

CADENAS hold future orientated industry forum

German software company CADENAS has held their 18th industry forum to discuss future orientated technology with over 200 visitors from a number of different industries. Held in Augsburg, Germany, the forum focused on Industry 4.0, BIM and the “optimization of the design process.”

KFC serving people with their food

Fast food chain KFC is using 3D printing to promote their new 5-in-1 I-Box product. KFC offered the first fifty customers at one of their Mumbai locations a 3D printed model of themselves. The customers were scanned in a booth before having their 3D printed miniature presented to them alongside the 5-piece fried chicken meal.

KFC executed the campaign with the help of Little Me a 3D printed figurine business located in Mumbai, India. Little Me brought a Twinstant Mobile full body 3D scanner to various KFC locations in India.

Don’t forget to cast your vote in the 3D Printing Industry Awards.

For the latest 3D printing news, sign up to our newsletter and follow us on twitter.

Featured image shows Sliced logo over screenshot from KFC India’s YouTube video.