Researchers from the University of Seville, Spain have developed a new method of producing highly-customizable composite filaments for the FFF 3D printing process.

The method uses pellet-like polymer capsules filled with magnetic additives. Using a 3devo Composer 450 filament maker – a single screw desktop extruder – the team was able to prepare a custom composite filament from the capsules, one with a uniform additive distribution and excellent printability properties.

Formulating filaments for FFF

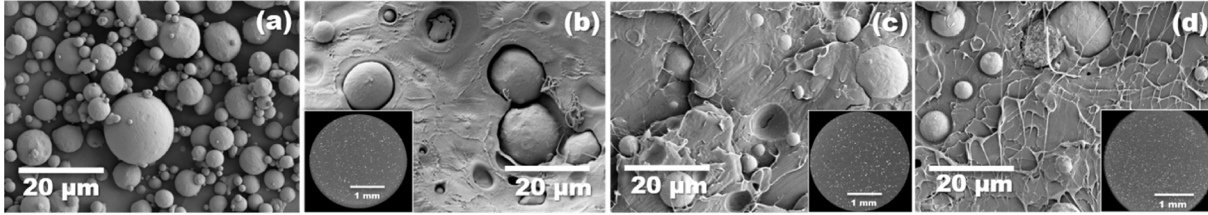

Filaments, and materials in general, can be further functionalized with additives – particles embedded in the base matrix that add strength or some other desirable property. In the case of polymer filaments, achieving a highly uniform additive dispersion can significantly increase homogeneity and maximize mechanical properties throughout the material. This tends to require several cycles of extrusion with a twin-screw compounder to really let the effects of entropy set in.

While the cyclic method is effective, it is often impossible without specialist production equipment that may not always be available to a research laboratory, not to mention the time commitment for multiple extrusion runs. As a result, materials studies are sometimes limited to the compositions and filler concentrations offered by commercial companies – a potential impedance in the way of science.

PLA capsules and steel powder

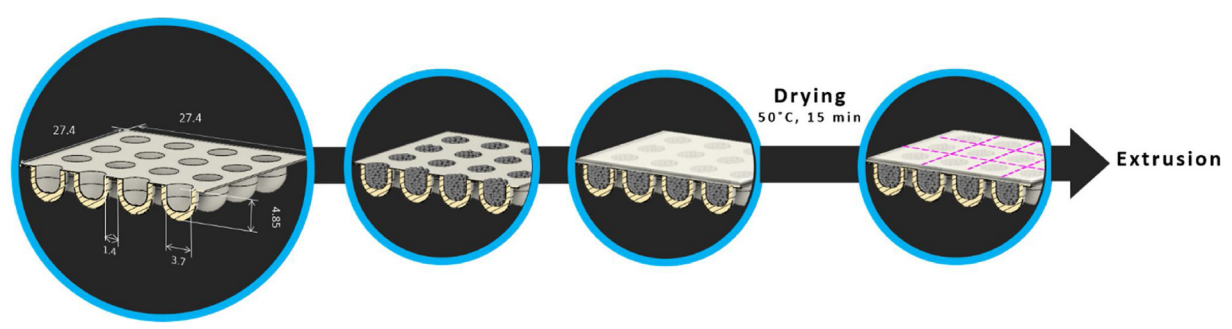

The first part of the Seville study involved formulating the new particle-filled capsules. The scientists used off-the-shelf PLA pellets to 3D print a grid of open-top hollow capsules (almost like an ice cube tray). The team then filled each capsule with soft magnetic maraging steel powder before closing off the tops with PLA lids and sealing them with acetone. The result: a set of highly customizable magnetic powder-filled PLA pods.

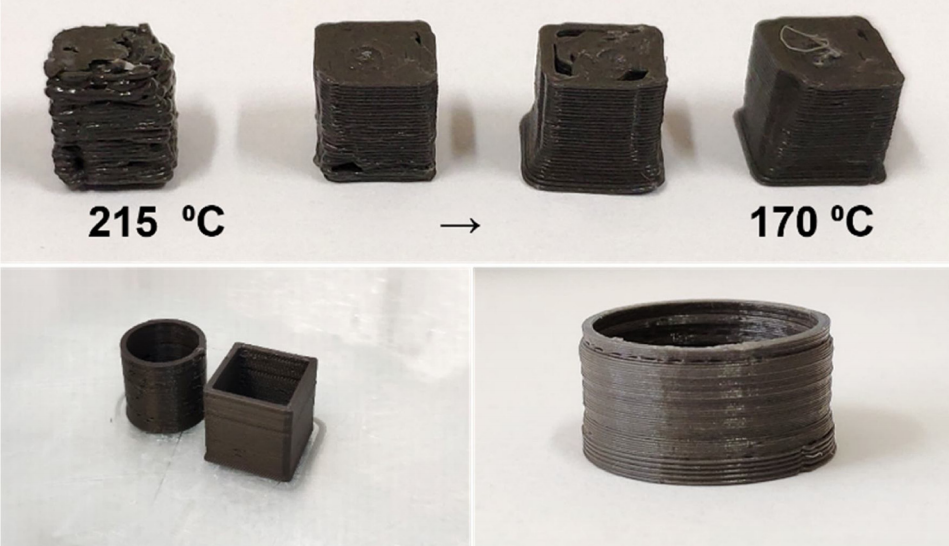

Then it came time to extrude the newly developed capsules to produce the final filament. Since the capsules were completely sealed off, the risk of the magnetic additive piling up and being retained at certain points in the extruder was eliminated. The PLA pods reached the melting zone of the extruder in one piece, enabling them to maintain their filler concentrations throughout the process.

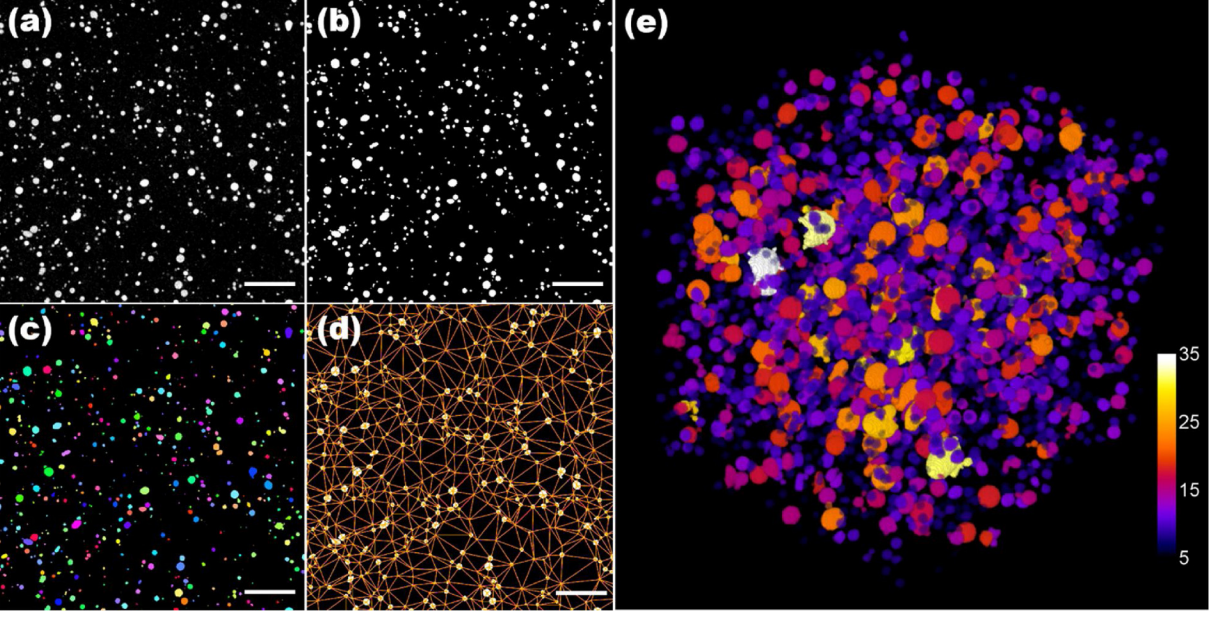

X-ray tomography imaging on the resultant filament revealed that the approach had created a smooth and continuous composite material with a uniform magnetic powder distribution. The researchers cite the need for only one extrusion run on a relatively low-cost single screw extruder as a major advantage of the method. Despite the lack of industrial resources, the team was still able to create a predictable and reproducible filament composition, and intends to extend the research to other polymer matrices and additives.

Further details of the study can be found in the paper titled ‘Novel procedure for laboratory scale production of composite functional filaments for additive manufacturing’. It is co-authored by Á. Díaz-García, J.Y. Law, A. Cota, A. Bellido-Correa, J. Ramírez-Rico, R. Schäfer, and V. Franco.

Multi-material composite filaments have gained traction in recent years as the technology used to print them has evolved. Earlier this month, 3D printer manufacturer RIZE debuted its new highly-durable RIZIUM Glass Fiber filament for use with its FFF 3D printers. The fiber-reinforced material has a high dimensional stability and stiffness, and is primarily intended for large part production.

Elsewhere, the US Army has taken it a step further and reinforced a polymer filament with another polymer filament. The high strength material has a polycarbonate core and an ABS shell, and is designed to be used with low-cost extrusion printers.

The 4th annual 3D Printing Industry Awards are coming up in November 2020 and we need a trophy. To be in with a chance of winning a brand new Craftbot Flow IDEX XL 3D printer, enter the MyMiniFactory trophy design competition here. We’re happy to accept submissions until the 30th of September 2020.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows X-ray tomography of the uniformly distributed steel in the PLA matrix. Image via University of Seville.