Based in Talinn, Estonia, Secured3D was a mystery to me. It is a start-up offering a secure cloud 3D printing service and their products were on show by Makerbot’s huge stand at the last Euromold. What exactly their ‘product’ was, however, is not so clear-cut. Their website did not help me figure out the issue that puzzled me the most: why would a cloud 3D printing service require a physical box? So in writing this article I was faced with two choices: simply limit my reporting to the fact that they exist and offer a service, or contact them and find out more.

Fortunately John Dogru, the company’s co-founder, answered my email instantly and, considering that another famous start up to come out of Estonia is Skype, we appropriately set up a videoconference. So I got the opportunity to virtually tour their headquarters and get a real feel for what they (John and 17 developers) are trying to do. Which is quite impressive: remote, secured, standardized and networked 3D printing through software, hardware or embedded electronics.

Let’s begin with the networking issue: why would someone need or want to print on more machines at the same time? “A lot can be said about the advantage of printing the same exact part, at the same time, on many machines throughout the world,” Dogru told me, “but the real issue here is to allow more people to remote 3D print on the same machine. That’s why we are looking to partner with Makerbot: their printers are not network compatible out of the box so many of the schools that are adopting them will be able to use our system to efficiently queue 3D print jobs on the same machine.” That is what the $699 box is for, so one mystery is solved.

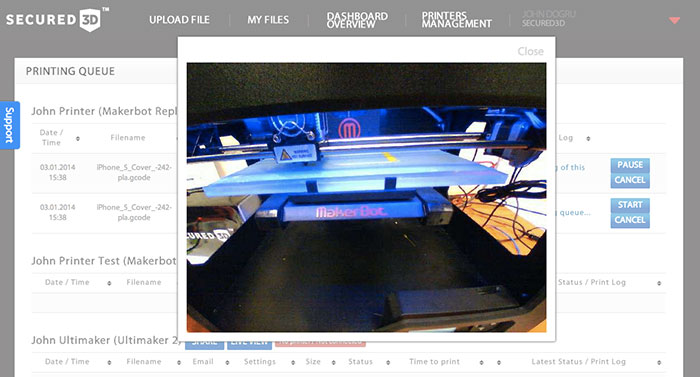

Networking also means you will be able to use the Secured3D platform for remote 3D printing, and, compared with other cloud printing services, it does offer some tangible advantages. One is the ability to get a real-time view of what you are 3D printing. To test the system I registered and uploaded a file to the Secured3D servers, selected a printer (John cleared me to use his Replicator 2 and set a limit of 100 prints), waited for the system to secure (encrypt) my file and hit print. Then all I had to do was select live view to see it happen, remotely, as if I were right there. Through an integrated map a large company can also keep track of all the 3D printing done worldwide on its models, through 3D printing partners around the globe. This would probably be done through the embedded system offer.

Once you get your customers to remotely 3D print one thing you will need to assure its security, which, as the name implies, is central to Secured3D, especially because they want to offer their service to high end designers and large companies that need to keep their IP’s and 3D modelled projects safe from copyright violations and industrial espionage. “Imagine you are GE and need to send secret military parts to be printed on US battleships and aircraft carriers throughout the world,” says Dogru, “you certainly do not want that design to fall in to the wrong hands. Nowadays it actually happens that designers and prototypers actually carry the model to the 3D printer saving it on an SD Card that gets burnt thereafter. It is an archaic method to use such an advanced technology. Our system is the most secure way to just stream a design to a remote printer without handing over the source file.”

So now you have your high end and low end customers doing multiple 3D prints remotely and securely. What is the last variable you will need to address to fully unleash the power of 3D printing? One word: “standardization”. A 3D model should always come out the same when printed with the same printer and that often does not happen today. So Secured3D intends to make sure that it does by embracing the Gcode standard for 3D files. In the case of FDM/FFF printers, the Gcode format includes all specifics on nozzle and plate temperature, allowing for an immediate, clear and standardized estimate of time and material requirements.

This service is specifically targeted at Makerbot’s Thingiverse network but any other producer, such as Ultimaker (or even Choc Edge), that want to offer an easy to use and efficient 3D model marketplace may end up taking advantage of it as well. Cloud based printing services and 3D printing optimization software such as netFabb, could integrate and take advantage of the security features.

Another service that, according to Dogru, may be able to take advantage of Secured3D is 3D Hubs, as a concern for some 3D Hub users is the different outcome that they get from different, privately-owned 3D printers: setting a common standard that can assure the same outcome might help them compete against other online 3D printing service offers. Of course the issue here is each Hub’s desire to actually offer a personalized service. Many Hubs arguably consider themselves 3D printing artists and the idea of simply hitting print on a standardized file may clash with this view. A mix of offerings, as is often the case, would likely be the best outcome, with standardization balancing out individualization of output.

There seems to be no lack of potential clients for Secured3D technology. “We have already presented our systems to 3D printer manufacturers such as EOS and 3D Systems, as well as 3D printing adopters such as Siemens,” says Dogru, the first orders are coming in and we have a lot of work to do.”

Evolution, after all, does not happen overnight.