A team of US researchers led by Virginia Tech has used 3D printing to create octopus-inspired adhesive suckers.

Octopi, along with other members of the cephalopod class, rely on a combination of controllable adhesives and embedded sensing to stick to and manipulate objects underwater. Many of today’s synthetic adhesive-based manipulation systems tend to be human-operated without any sort of integrated sensing, which can result in relatively slow adhesion activation and release.

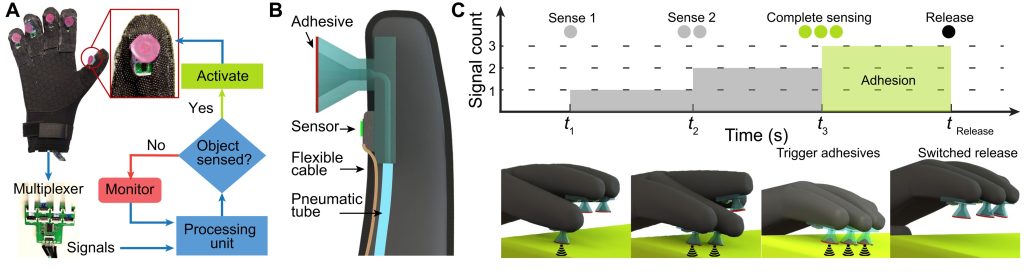

The Virginia Tech research team has now developed its own nature-inspired nervous system capable of detecting objects and automatically switching on adhesion in a matter of milliseconds.

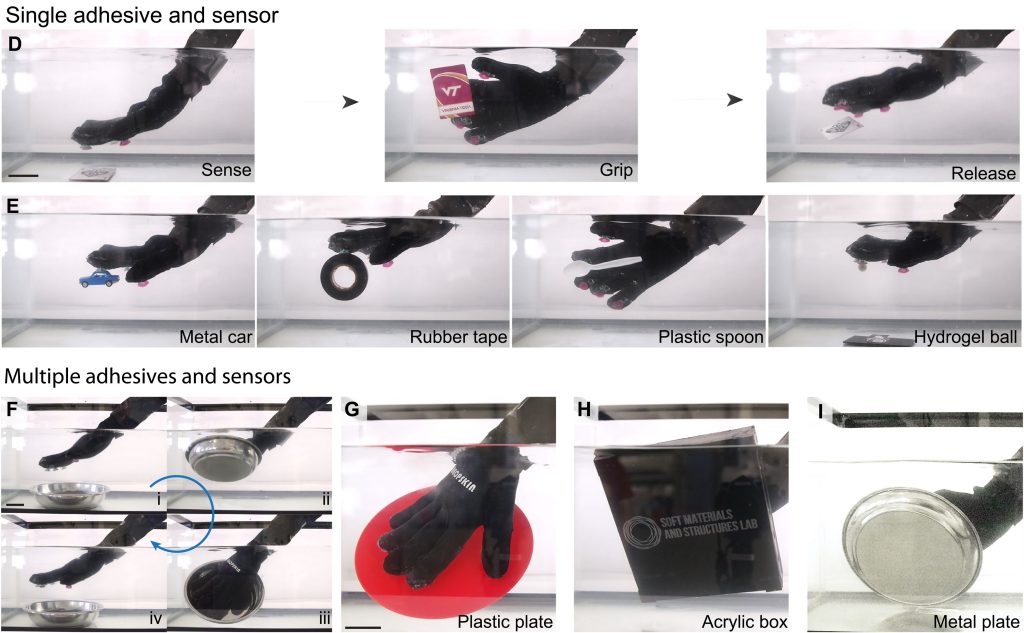

Having implemented the 3D printing-enabled adhesive skin into a wearable glove, the scientists have created a novel approach to reliably manipulating objects in an underwater environment.

Mother nature knows best

To this day, effective and reversible adhesion to underwater surfaces remains a major challenge. In dry environments, we can rely on adhesion via van der Waals forces, electrostatic forces, and hydrogen bonds, but wet surfaces significantly reduce the efficacy of these phenomena.

Still, evolution has graced the animal kingdom with several methods of creating strong adhesive forces in the wettest of environments, including underwater. For example, mussels can secrete special proteins to create a sticky plaque that allows them to stick to almost any surface. Similarly, frogs can excrete fluids through their toe pads to activate hydrodynamic forces.

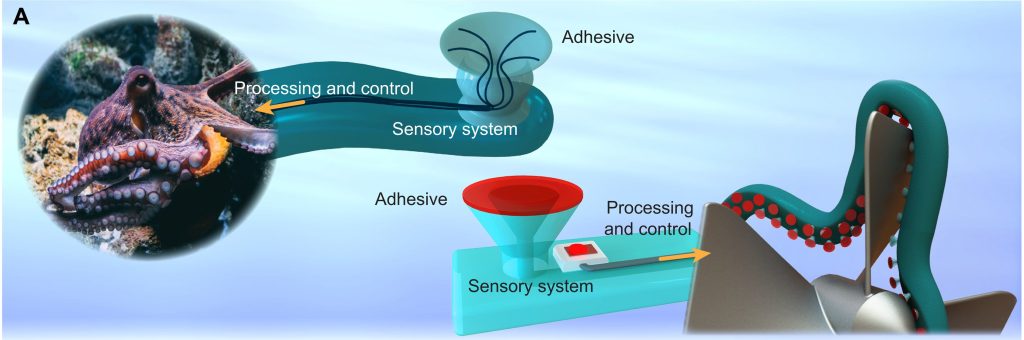

Octopi are of particular interest as their suckers are able to generate underwater adhesion and suction forces very quickly, all while being completely reversible. They’re also noteworthy due to the sensing and control system that accompanies the suckers, which comprises mechanoreceptors that serve to detect fluid flow, pressure, and surface contact.

This combination provides them with comprehensive information on factors such as attachment and proximity – capabilities that are hard to come by in modern-day synthetic grippers.

Emulating the octopus nervous system

Virginia Tech’s octopus-inspired glove featured a set of silicone stalks capped with pneumatically actuated membranes to act as grippers. The stalks were made with the help of 3D printed molds, whereby silicone elastomer was poured into the molds and cast and cured into the custom gripper shapes.

Each of the adhesive suckers was integrated with an array of microlight detection and ranging (LIDAR) optical proximity sensors. The gloves also featured microcontrollers for real-time object detection and sucker control. The team claims this combination of mechanical and electronic equipment accurately mimics the inner workings of the octopus nervous system.

Upon testing the gloves in a series of underwater trials, the researchers found that their device enabled adhesive stresses of more than 60kPa. The adhesion in the gloves could also be switched on and off over 450 times in less than 50ms, demonstrating excellent reversibility with cycle times faster than that of real octopi.

The paper concludes, “Although this study is focused on optical sensors, different sensing modalities could also be used in the future. Chemical or mechanical sensors could be synergistic, and this could be particularly interesting as it is known that the octopus displays a diverse set of vision, chemical, and mechanical sensing during manipulation. There are also future opportunities to incorporate haptic feedback into this system to alert a user when adhesives are activated.”

Further details of the study can be found in the paper titled ‘Octopus-inspired adhesive skins for intelligent and rapidly switchable underwater adhesion’.

Biomimicry is a common thread in additive manufacturing research, and for good reason. Earlier this year, researchers at ETH Zurich 3D printed artificially colored nanostructures, drawing inspiration from the wings of a butterfly. Native to tropical Africa, the wings of the Cynandra opis species are characterized by their vibrant colors. Rather than being pigment-based, however, these colors are structural, meaning they’re produced by intricate nanostructures on the surface of the wings.

Elsewhere, researchers from the University of Freiburg and the University of Stuttgart developed a novel method of 4D printing wearable medical devices that self-adjust to the anatomy of the patient. Inspired by the propagation mechanism of the air potato plant (Dioscorea bulbifera), the printed systems can be pre-programmed to carry out complex movements when exposed to moisture.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the nervous system of an octopus sucker. Image via Virginia Tech.