The 2021 3D Printing Industry Awards shortlists are now open for voting until the 20th of October. Cast your votes here.

Scientists from Pacific Northwest National Laboratory (PNNL) have developed a new seaweed-based bioink for 3D printing.

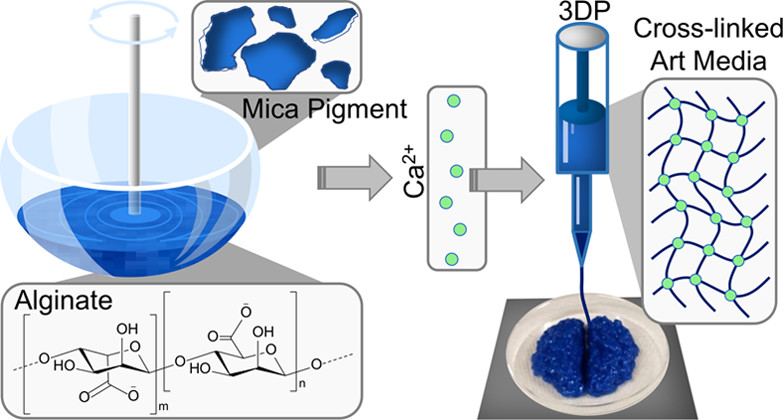

Dubbed ArtSea Ink, the biodegradable material is made largely out of alginate, a naturally occurring polymer typically found in brown seaweed. Alginate is biocompatible, low cost, and can be used to form a stable gel without heat, meaning it can be extruded at low temperatures to form 3D structures.

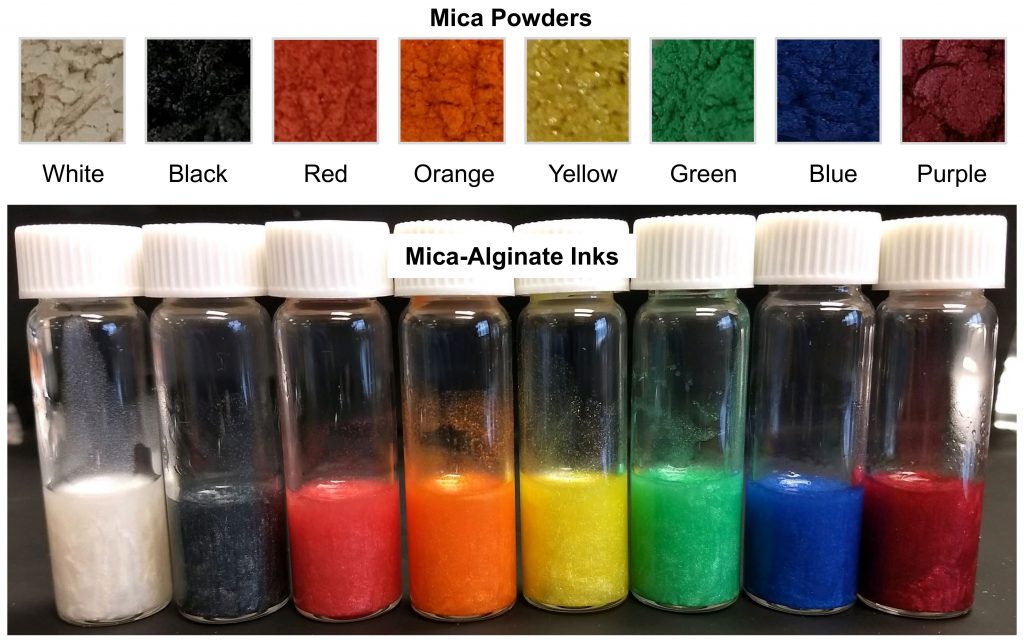

To bring their creation to life, the PNNL team also integrated fine mica pigment powders into the formulation, resulting in a set of colorful, vibrant inks well suited to artistic applications.

3D printing as an artistic medium

When we hear the term ‘3D printing’, we might imagine some of the more industrial use cases of the technology: a complex rocket nozzle component made of titanium or a tool steel fixture for an automotive production line. Recently, however, the modern art world has also begun to embrace additive manufacturing as a creative medium, owing to the inherent design freedom it grants.

Right now, the majority of 3D printed art relies heavily on polymer-based materials as these come ready-made in a wide variety of colors at low prices. Unfortunately, polymer-based materials tend to require high temperatures for melting and fusion/extrusion. This heat limitation forces artists to choose between either FDM or SLS systems to work with their polymer media.

If an artist wanted to opt for a process like direct ink writing or even a custom extrusion-based system with no in-built heating element, they would indeed require a custom low-temperature material for the job. This is where biologically derived polymers come in.

Bio-polymers for 3D printing

Alginate has previously been explored as an accessible bioink, since the compound forms a viscous gum when mixed with just water. This gum can be transformed into a robust, printable hydrogel when cross-linked with calcium ions. Unlike petroleum-derived polymers, however, alginate only ever comes in a colorless offering, so the PNNL team had to integrate the colors manually using mica powders.

Specifically, the researchers prepared eight different 8% alginate solutions in water and added eight different colors of mica pigments to them. They also found that they could closely control the texture of the inks by varying the amount of calcium chloride crosslinker.

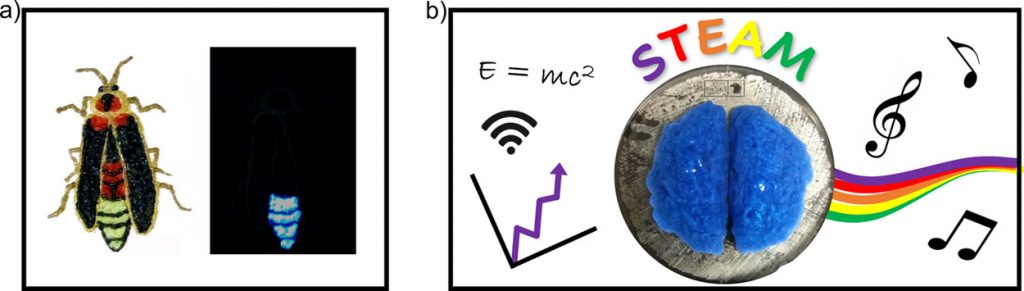

To test the newly formulated ArtSea bioinks, the team then 3D printed a glow-in-the-dark firefly as well as a bright blue anatomical model of the human brain.

Although the 3D printed art was only stable for a couple of weeks (when kept in a calcium chloride solution), the team believes this is an advantage as it means the material will biodegrade rapidly when discarded. Conventional polymers, on the other hand, can sit in landfills for centuries.

Further details of the study can be found in the paper titled ‘Pearlescent Mica-Doped Alginate as a Stable, Vibrant Medium for Two-Dimensional and Three-Dimensional Art’. It is co-authored by Anne Arnold, Zachary Kennedy, et al.

In the art world, Maltese ceramic artist Nico Conti turned heads at this year’s virtual Collect art fair with his intricate 3D printed porcelain sculptures. To create his unique structures, Conti blended computer design and 3D printing with inspiration from classical ceramics, architecture, and nature, in order to purvey elements of “distortion, collapse, and ruin.”

Elsewhere, a Japanese art retailer by the name of Shuhei Okawara recently began offering hyper-realistic 3D printed face masks at his shop in Tokyo. With a price tag of 98,000 yen ($900), the masks won’t halt the spread of the coronavirus, but they will allow wearers to don the facial features of a random stranger.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the eight different mica powder-infused alginate-based bioinks. Photo via Pacific Northwest National Laboratory.