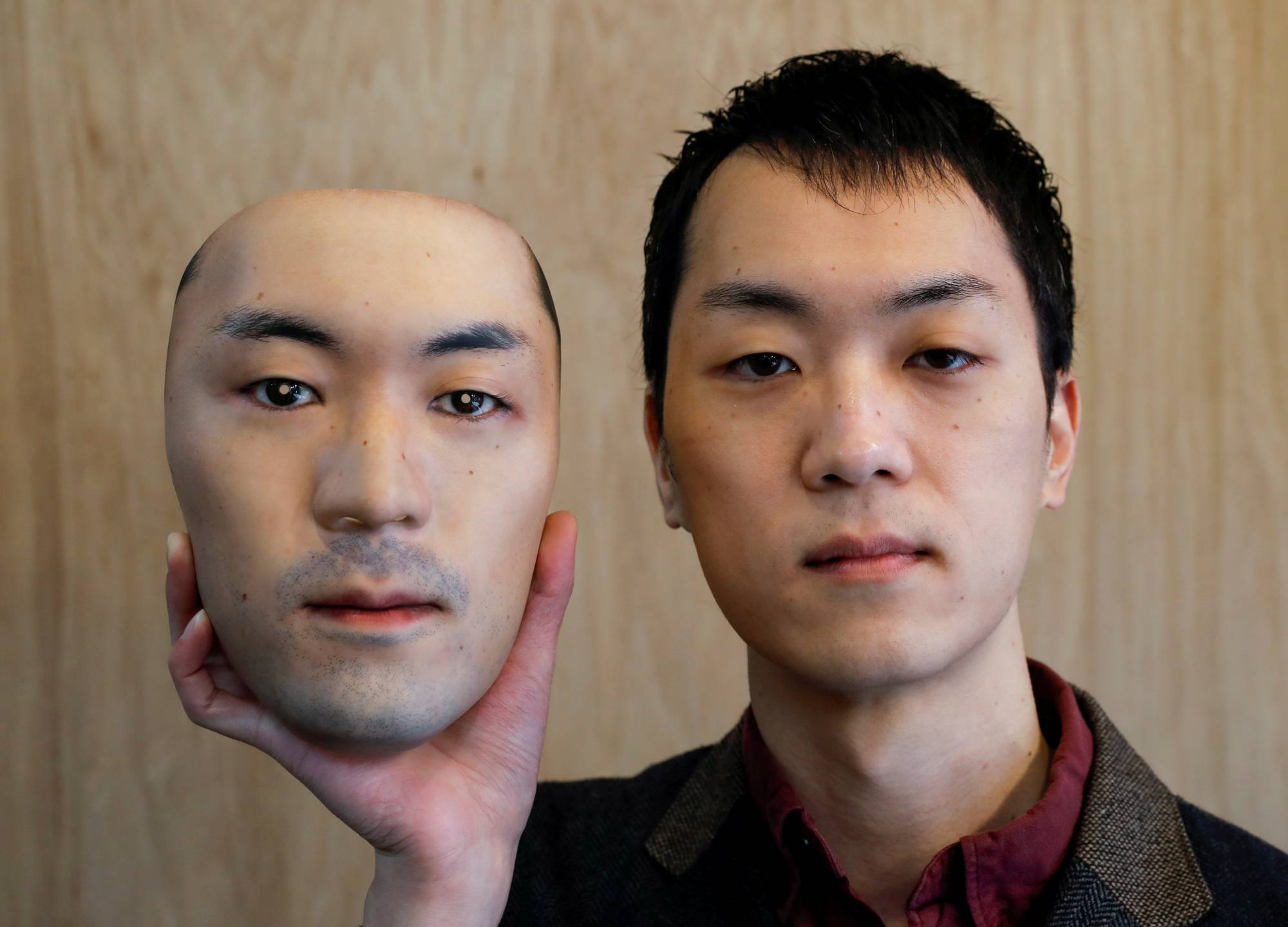

In the midst of our new mask-centric society, a Japanese arts retailer is set to begin offering hyper-realistic 3D printed face masks.

While Shuhei Okawara’s masks aren’t designed to halt the spread of the coronavirus, they will allow wearers to don the facial features of a random stranger. Okawara intends to launch his product in Spring of this year, with a price tag of 98,000 yen ($950). Anyone interested in viewing the masks in person can do so at his shop in Tokyo, Kamenya Omote, where he sells accessories for parties and theatrical performances.

In an interview with Reuters, Okawara said, “As is often the case with the customers of my shop, there are not so many people who buy (face masks) for specific purposes. Most see them as art pieces.”

A penny (or 40,000) for your thoughts

Okawara initially launched his avant-garde project back in October, when he received headshots from over 100 prospective applicants. Upon choosing a lucky stranger’s photo, he paid the person 40,000 yen ($350) for the rights to use their face, and has stated plans to add more faces to the lineup in the coming months, including those of non-Japanese models. It’s worth noting that masks are never created without explicit permission from the owner of the face.

The very first model, which was of his own face, has already sold out after pre-orders were made available on the shop’s website. Based on this response (and the 50+ inquiries he receives every day), he expects extremely high demand for his future masks. Okawara claims he has even been approached by celebrities to reproduce their faces, and while this may result in more sales, he says he’d rather do it for the sake of the art and have fun.

100 masks a month

To 3D print the plastic masks, Okawara is working closely with an engineer from an unnamed printing company. The novel technique requires a face to be 3D scanned to create a high-resolution virtual model. Then, the full-color 3D scan is manually touched up to prepare it for the 3D printing process, at which point it is printed out onto a base template. As it stands, the “trade secret” method allows Okawara to produce around 100 face masks every month.

Okawara concludes, “Mask shops in Venice probably do not buy or sell faces. But that is something that’s likely to happen in fantasy stories. I thought it would be fun to actually do that.”

While additive manufacturing certainly has its uses in heavy-duty engineering applications, there is something to be said about its affinity for artistic purposes. Late last year, Historic Environment Scotland was able to reveal what dogs from the stone age may have looked like via 3D printing. Specifically, the organization commissioned a reconstruction of a Neolithic canine skull, which is thought to be around 4500 years old.

Elsewhere, global engineering company Renishaw used 3D printing to produce a replica of a 12th Century Gloucester Candlestick. The candlestick, a historic product of early-twelfth century English metalworkers, was originally commissioned by Abbot Peter for the Church of St. Peter, and was relocated several times over the centuries until it settled in the V&A museum in Central London.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Shuhei Okawara holding a mask of his own face. Photo via Shuhei Okawara.