Creative design studio Urban Scale Interventions (USI) has created an immersive lighting piece and soundscape in Belfast’s historic ‘Entries’ using 3D printing and recycled filament.

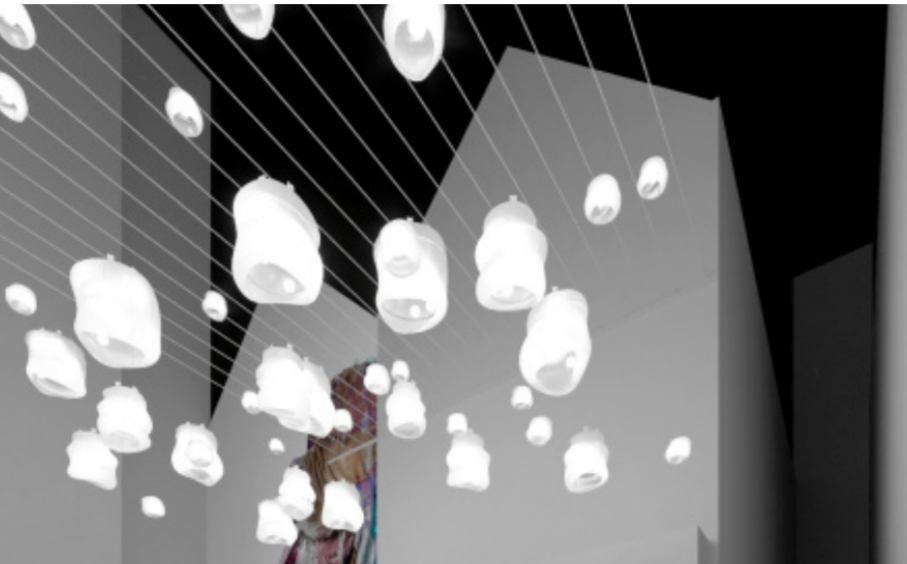

Made up of 43 suspended ‘ocean orbs’, the lighting piece is the result of a contract won by USI in 2020 to reimagine the city’s central vision to lighting. The orbs were created using Ultimaker S5 3D printers and recycled PETG filament from Filamentive, and were designed to improve safety in the area and reflect the historic significance of the site.

Lighting up Belfast’s ‘Entries’

Steeped in history, the ‘Entries’ in Belfast are a series of narrow alleyways that connect many of the main city center streets and districts. The Entries are still used today as cut-throughs and gathering spaces for outdoor dining by bars and restaurants, although over the years they have experienced antisocial issues and irregular lighting.

In 2019, the Belfast City Council began a new strategy to establish a ‘placemaking’ approach to lighting the city’s Entries, and worked with USI to develop a co-designed vision for lighting the city. Last year, USI won a contract last year to produce an immersive lighting piece that both celebrates the history of the site and offers a more welcoming environment to visitors.

One of the sites chosen to receive a specialist lighting boost was the square outside Whites Tavern, one of Belfast’s oldest Irish bars. The installation’s 43 large suspended ‘ocean-like’ orbs were influenced by the sites’ history as an oyster market, and change color in line with an ambient soundscape to create a relaxed and reflective atmosphere for visitors.

Prior to the installation of the orb lights, the area was a void space. With Covid restrictions in place, outside drinking and dining was one of the only ways for people to meet with friends and family, and so the new light installation provided visitors with a welcoming space to socialize safely.

Lighting the way with 3D printing

USI turned to 3D printing to bring their immersive lighting installation to life due to the increased flexibility allowed by the technology to design the bespoke orbs and test prototypes. The team leveraged the capabilities of Ultimaker’s S5 3D printer to manufacture their orbs at scale in-house at a reduced cost than they could have hoped using alternative methods.

USI also took advantage of Ultimaker’s Material Alliance Program, which allows filament companies to offer their products and print profiles in the Ultimaker Marketplace, in order to gain greater material efficiency. The firm wanted to produce the orbs from a translucent recycled material in order to make a design statement regarding the potential of more sustainable and recycled materials within the built environment.

USI settled on Filamentive’s clear PETG filament due to its ability to deliver the strength and translucency required for the suspended lighting, and for its sustainability credentials. Filamentive PETG is made from high-percentage recycled plastic that would otherwise go to landfills if not reused.

The material also features a 100 percent recycled cardboard spool to minimize plastic waste, and Filamentive also commits to tree plantation with at least one kilogram CO2 offset for every kilogram of plastic it sells.

According to USI, since the lighting feature has been installed it has become a focal point of Whites Tavern and has become very “instagramable” among visitors.

Ultimaker CEO Jurgen Von Hollen recently outlined the firm’s intention to build a portfolio around flexibility and the “idea of open innovation”, as it aims to keep pace within the continually shifting production environment.

The company’s S5 3D printers have been leveraged by customers for a wide variety of applications in a range of sectors. The S5 was originally launched in April 2018 for professionals using 3D printing for prototypes, tools and end-use parts, and was also given the green light for medical 3D printing applications. The following year, Ultimaker launched its S5 Pro Bundle with added hardware to improve the safety and material usage of the machine.

The S5 has enabled international industrial equipment supplier ERIKS to scale up its 3D printing capabilities for OEM and MRO customers, helping them to identify, design, and print parts according to specific industry standards, including those related to food safety and cleanliness.

Elsewhere, up to 75 Ultimaker S5 printers will be deployed to US Navy and Marine bases across the US and overseas over the next five years, as part of a new $5 million contract between 3D printer and filament supplier MatterHackers and the Naval Air Systems Command (NAVAIR).

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows Ocean Orb lights suspended above the square outside Whites Tavern in Belfast. Photo via Ultimaker.