Russian construction company Renca, has developed an eco-friendly cement for 3D printing. According to the manufacturers, production of the material, known as géobéton (geoconcrete or geocement), reduces carbon dioxide emissions by up to 90% when compared to the traditional mode of making cement. By using recycled materials, the material also creates at least 60% less impact on the environment than its Portland counterpart.

The hope is to use the material to 3D print buildings, particularly in Dubai – a city that is aiming to 3D print 25% of its buildings by the year 2030.

3D printing the geocement. Clip from géobéton (geopolymer concrete) for 3D printer Apis-Cor by Andrey Dudnikov on YouTube

Laying the foundations

Renca was founded in 2016 by businessman Andrey Dudnikov and geologist Alex Reggiani. According to the company’s Chief Financial Officer, Dudnikov’s wife and business partner Marina Dudnikova, the company started as a reaction to the financial crisis of 2014. Already part of the construction industry, the founders saw a way to do things differently and independently of their employers at the time.

Made from ash and slag

Renca’s géobéton is made from the ash produced by burning powdered materials like coal, and granulated blast slag created as a by-product of separating metal from its ore.

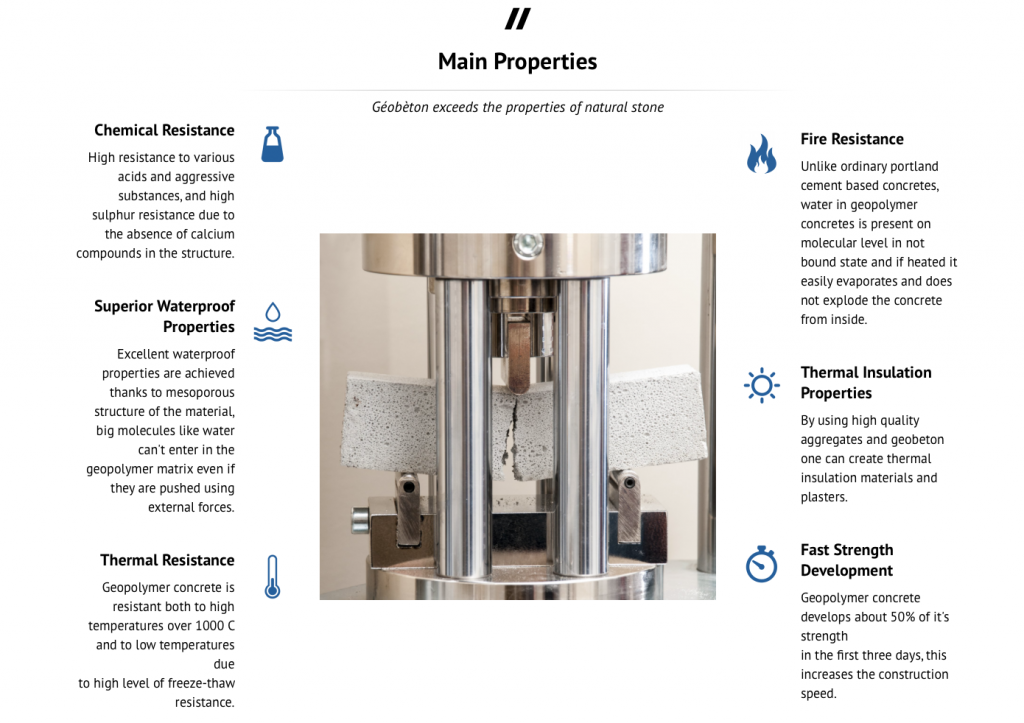

In addition to its low-impact on the environment, the resulting material has a range of advantages over traditional Portland cement, including it’s resistance to water and fire.

3D printing with Apis Cor

3D printing tests of the geocement have been performed by the Apis Cor 3D printer. Also based in Russia, Apis Cor made headlines at the beginning of March 2017 by 3D printing a house in just 24 hours.

Speaking to The National newspaper, Dudnikov explains the qualities needed to make géobéton 3D printable. He says,

It should be fluid enough for the 3D printer and it should set very quickly. When the first layer is in place, the second layer will come straight after. To achieve this with normal concrete you have to add a lot of additives, so it becomes expensive. With geopolymer concrete, you can adjust the properties of the cement with the amount of raw materials you add. It’s easy to regulate, achieves fast settings and it is easy to use in these [hot] temperatures.

An international trend

Other companies in the business of 3D printing buildings include China’s Winsun, who also have interest in the UAE, and Dutch company CyBe.

Designers at the Institute for Advanced Architecture of Catalonia (IAAC) in Barcelona are one institution also looking to create more eco-friendly materials for 3D printing. In a collaboration with ACCIONA, a company dedicated to Spain’s sustainable infrastructure, the IAAC is responsible for the “world’s first” 3D printed bridge, which is made from finer-reinforced concrete.

To stay up to date with the latest development for 3D printing in construction, sign up to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Readers can also give recognition to 3D printing innovation by voting now in the first annual 3D Printing Industry Awards.

Featured image shows the powdered geocement produced by Renca and 3D printed by Apis Cor. Image via Apis Cor