RPS, a UK-based industrial 3D printer OEM, has joined global material producer DSM’s collaborative program designed to accelerate the adoption of additive manufacturing.

The Trimax Collective offers companies the flexibility to own and invest in 3D printing hardware and materials via a lease scheme, as well as receive training and support for such technologies. As such, businesses can lease the RPS NEO800 stereolithography system and DSM resin to optimize production processes.

“Moving away from traditional subtractive manufacturing toward additive can be a daunting experience for some manufacturers,” said David Storey, Director of RPS.

“The Trimax Collective is a perfect solution as it is tailored to customers who want to explore 3D printing further, but who need the guidance, support, and flexibility to start the journey.”

“The foundation on what RPS is built on is an outstanding support we offer our customers and the Trimax Collective is reflective of this ethos, so we are delighted to be part of this partnership with DSM.”

The Trimax Collective

Launched before the RAPID + TCT conference in Detriot last month, the Trimax Collective was introduced as the “first ever all-inclusive 3D printing solution [to] take advantage of DSM’s many partnerships across the 3D printing value chain.” Presently, RPS operates as a reseller for DSM Somos and EOS Group laser sintering materials company ALM.

Hugo da Silva, Vice President of DSM Additive Manufacturing, explained, “The Trimax Collective allows us to tackle the two biggest barriers to the widespread adoption of 3D printing that exist today: high investment requirements and a lack of experience with AM.”

“The Trimax Collective is DSM’s way of channeling the power of our AM ecosystem to the benefit of our customers. Thanks to this program, 3D printing will become more accessible than ever before.”

The RPS NEO800

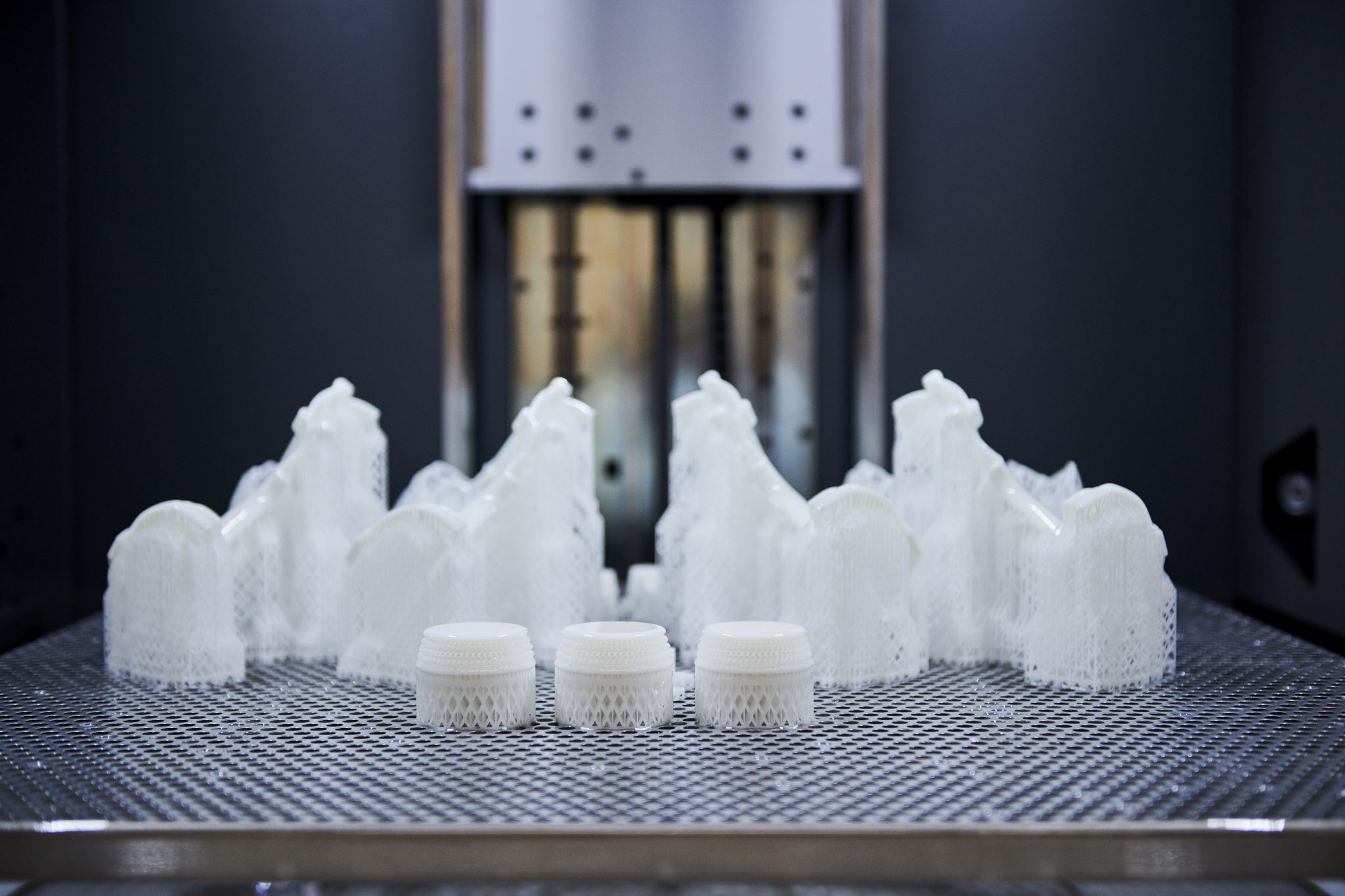

The RPS NEO800, first introduced in 2016, is engineered to produce high-quality parts using its dynamic laser focusing capability. The print area of the NEO800 is 800 x 800 x 600mm, with the machine measuring 1350 W x 1630 D x 2300 H mm. Its large size accommodates for the production of automotive components.

Such parts are said to maintain exceptional sidewall quality, with scanning resolution to within a single micron. The NEO800 also offers an open materials platform enabling any 355 nm polymer to be processed by the system. As Storey explained when 3D Printing Industry visited the RPS HQ, “Our system is not locked to a specific manufacturer. This allows research specialists to develop new materials.”

Through the Trima Collective, manufacturers will be able to utilize DSM’s

material expertise in tandem with the RPS NEO800 to create industrial-grade 3D printed products as well as components used for prototyping.

Find the latest additive manufacturing news by subscribing to our 3D Printing Industry newsletter and following us Facebook and Twitter.

Also, visit our 3D Printing Jobs board to find out more about opportunities in additive manufacturing.

Featured image shows models produced on the NEO800. Photo via RPS.