For the first time, UK industrial 3D printer OEM and support provider RPS will be exhibiting at the 2019 Additive Manufacturing User’s Group (AMUG) Conference in Chicago. Already a well established company within 3D printing RPS, as part of the parallel AMUGexpo on March 31 and April 1 2019, is seeking to deepen its connections in North America. Harnessing its industrial expertise, and the global support system at the core of its business, RPS will be on hand to share unique insights and solutions for professionals working in polymers.

“We see AMUG as an introduction to grow our business into the North American market,” comments RPS Director David Storey, “The NEO800 system that we manufacture in the UK has a proven install base in Europe and is an exceptional product.”

“We want to use AMUG as an opportunity to create a reseller distribution network and to showcase our products and services on a global basis.”

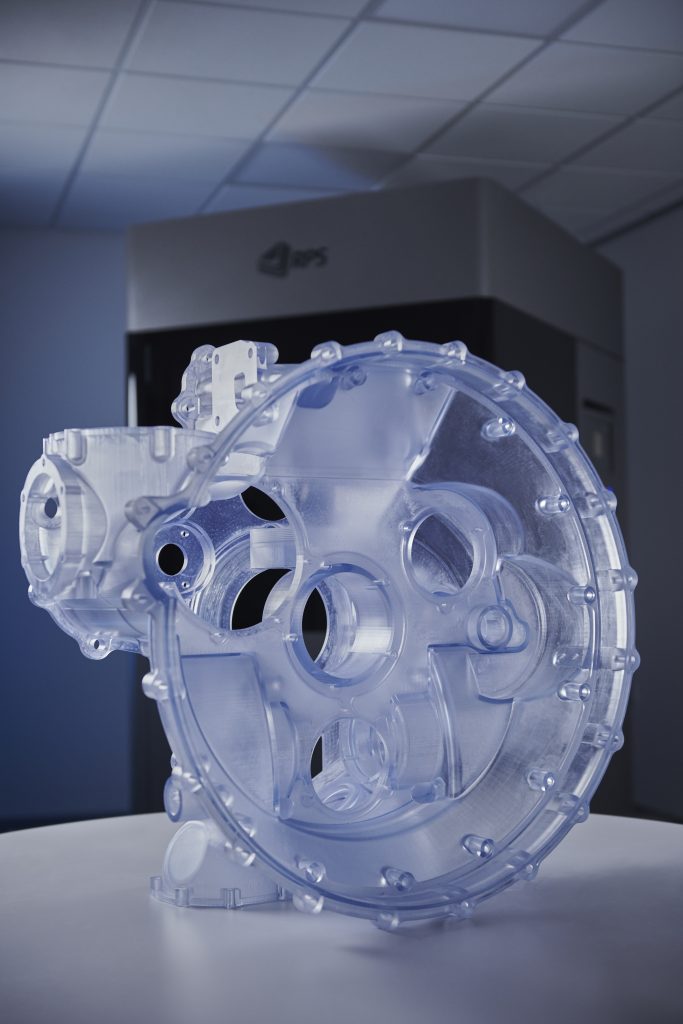

RPS’ flagship system, the NEO800, is a large-format SL 3D printer introduced by the company in 2016. A number of industrial applications completed on the NEO800 will be on display in Chicago, including prototyping and injection molding.

Industrial 3D printer support services

RPS was founded in 2008. It is headquartered in Buckinghamshire, South East England, and has a global network of engineers with proven experience in 3D printing, engineering, electronics, computer-aided engineering and more. A dedicated team of highly skilled and knowledgeable personnel, this team offers advice, service and assistance on a range of 3D printing technologies and materials. Specifically, RPS expertise lies in SLS and SLA 3D printing, plus other areas such as laser refurbishment, system upgrades, and system repairs.

In addition to machine development and customer support, RPS also operates as a reseller for HP 3D printers, and materials from HP, DSM Somos and EOS Group laser sintering materials company ALM.

Inside the NEO800 SL 3D printer

Through many years of applied machine knowledge and experience, plus time spent supporting customers, RPS determined that the NEO800 should be an entirely open materials platform. This means that any 355 nm polymer can be processed by the system. As Storey explained when 3D Printing Industry visited the RPS HQ, “Our system is not locked to a specific manufacturer. This allows research specialists to develop new materials.”

“Up until now, material development has been a rather closed community.”

Not wanting to be held back in terms of capabilities, the NEO800 is engineered to produce high quality small parts as effectively as it can fabricate large, detailed models. This is due to the machine’s dynamic laser focusing capability. Parts produced on the system have exceptional sidewall quality, with scanning resolution to within a single micron.

RPS Titanium 3D printer control

The NEO800 is controlled by RPS’ proprietary Titanium software. Accessed via touchscreen, Titanium currently runs on a Windows 10 platform. From the main Titanium interface, users can access Build, Parameters, System and Information menus, allowing control at every stage of the build.

Pre-build features include model validation, a user-definable stir function, build time estimation, bubble remover and other manual and automated options.

When a build has started, Titanium allows users to change a number of settings mid-build. It also allows operators to delete parts and supports, with the option to view progress through the in-built camera.

Post-build, Titanium offers part traceability, build history, machine utilization and diagnostic logs. These report functions feed into RPS’s support network, allowing customers to send any feedback or suggestions with full relevant documentation. Such data is all used at RPS to implement updates to its Titanium software, something that the company takes great pride in.

“We are an innovative company at the forefront of technology,” concludes Storey.

“We are a team of passionate people who care. This comes across in the design and manufacture of the NEO800 and why we focus on providing our customers with outstanding service and support.”

AMUG 2019 visitors will be able to visit RPS in Chicago this year at booth 28. If you are interested in becoming an RPS partner within North America or Worldwide, or just looking for more information email RPS at [email protected].

For more of the latest 3D printing events and other news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Seeking jobs in engineering? Make your profile on 3D Printing Jobs, or advertise to find experts in your area.

Featured image shows NEO800 large scale SL 3D printers at RPS in the UK. Photo via RPS