Global science company and material manufacturer Royal DSM, has partnered with San Francisco-based 3D printing startup Origin. The goal of this collaboration is to develop new materials for additive manufacturing, and marks another boost for Origin’s Open Additive Production platform.

Specifically the two entities will focus on the optimization of Royal DSM photopolymer materials for Origin’s programmable P3 3D printing platform.

Open Additive Production

Founded in 2015, Origin began as a 3D printing bureau, since then it has been developing its own additive manufacturing platform termed Open Additive Production. The platform includes Origin’s own resin-based photopolymerization 3D printers the P3 – a modular hardware system with open materials compatibility and extensible software. The aim of the platform is to introduce more flexibility and the volume of parts produced during the 3D printing process.

Central to Origin’s Open Additive Production is working with material developers to create formulas specifically for Origin’s technology, rather than Origin creating thousands of formulas for niche uses on its own.

Commenting on the latest addition to its platform Chris Prucha, Origin’s CEO and Co-founder said, “We’re excited that DSM is joining our open network of material partners and broadening the potential applications available to our users.”

“DSM is the market leader in world class photopolymers with decades of experience developing unique photo-reactive chemistries. Together we are addressing today’s manufacturing challenges for customers.”

DSM is the third material development company to join Origin’s network In November 2018 chemical giant BASF became the first, the result of which includes a new range of photopolymers based on the Ultracur3D line. In February of this year Henkel became the second, working with Origin on the validation of biocompatible materials, which includes Henkel’s silicone resins.

Optimizing DSM’s additive materials

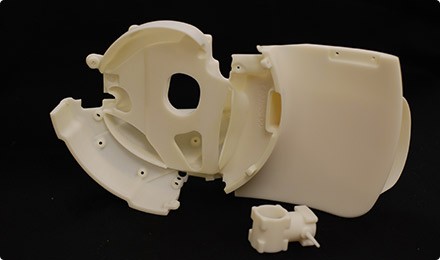

The first material to be developed under the DSM partnership is Somos® PerFORM HW, a composite material optimized for Origin’s P3 technology.

Based on DSM’s Somos® PerFORM,a material intended for SLA, – it mimics many of the same properties, including strength with a Tensile Strength after Thermal Postcuring of 80 MPa and resistance to high temperatures up to 260°C .

“The quality and surface finish we’re seeing with Somos® PerFORM HW on Origin’s P3 process are outstanding and unparalleled,” says Noud Steffens, Market Development Director additive manufacturing at DSM.

“Origin provides an unprecedented degree of control so users can get consistent commercial-grade results using Somos® PerFORM HW and soon other DSM materials.”

DSM’s Somos® PerFORM HW will be presented alongside Origin’s P3 printer during the 2019 RAPID + TCT show which takes place from May 21 to 23 in Detroit. DSM will be in booth 303 and Origin will be located in booth 2153.

Vote for your 3D Printing Innovation of the Year in the 2019 3D Printing Industry Awards.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook. Looking for a career in additive manufacturing? Visit 3D Printing Jobsfor a selection of roles in the industry.

Featured image shows a sneak peak at Origin’s P3 printer which will be showcased at RAPID + TCT 2019. Photo via Origin.