Global science-based company and material producer DSM is to partner with large-scale 3D printer supplier CEAD. Focusing on Fused Granulate Fabrication (FGF), a type of material extrusion, the two entities will pursue the development of new feedstock, tooling and end-use applications.

According to Patrick Duis, Segment Leader Transportation at DSM Additive Manufacturing, comments, “By expanding our offering to FGF materials, DSM gives manufacturers across the globe maximal flexibility in choosing the material and technology that best suits their desired application.”

“FGF technology allows us to use highly filled polymers that increase the thermal, mechanical needs and the performance of our application and thus takes us closer to injection molded parts.”

The ecofriendly 3D printing method

FGF is a relative of fused filament fabrication (FFF) that, in place of a filament, uses chopped, pelletized feedstock as a material source. Essentially, this process removes the “middle man” of filament extrusion, instead converting raw material, even recycled polymers, directly to the print bed.

Though some 3D printer OEMs are bringing FGF machines and compatible printheads to market, in comparison to its filament relative FGF is nowhere near as widely used. As explained in a 2018 article by Michigan Technological University’s (MTU) Aubrey Woern and Joshua Pearce, FGF is still held back by “the accessibility of low-cost pelletizers and choppers.” One possible solution, also explored by Woern and Pearce, is open-sourcing the construction of chopping and pelletizing equipment.

Still, applied effectively, FGF has proven to be a more environmentally friendly and economical method of 3D printing. It is also a common choice for large-scale polymer additive manufacturing, due to the achievable speed of its inherent screw-extrusion system.

The advanced application of FGF

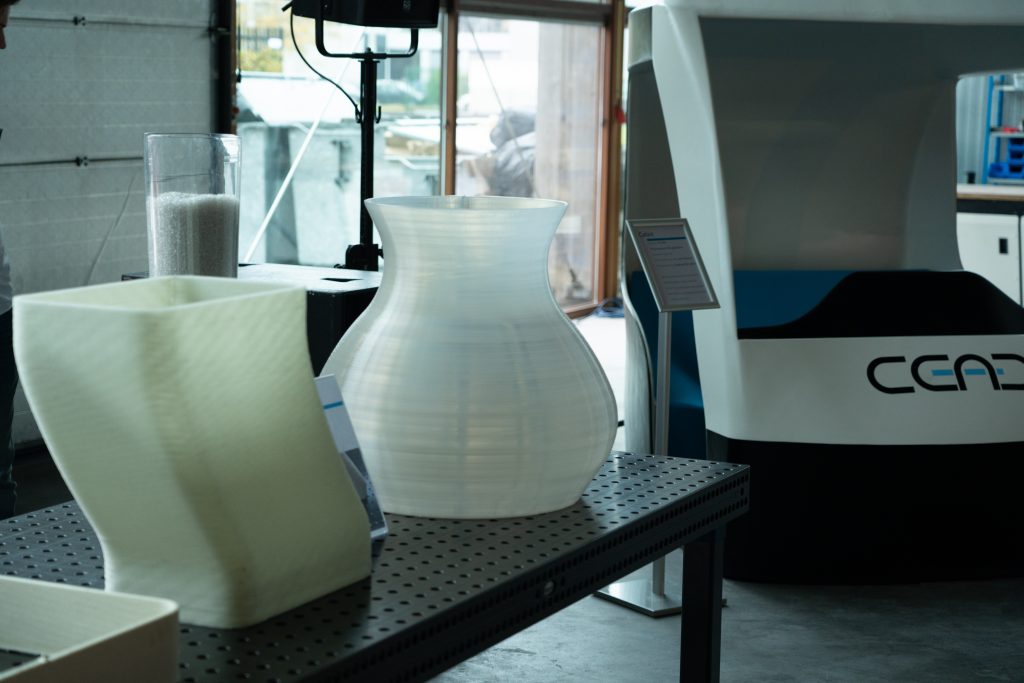

CEAD is the developer and provider of large-format Continuous Fiber Additive Manufacturing (CFAM) machines. In November 2018 the company launched its first system, the CFAM Prime, with marine engineering company Royal Roos and fiberglass reinforcement specialist Poly Products as the first two customers.

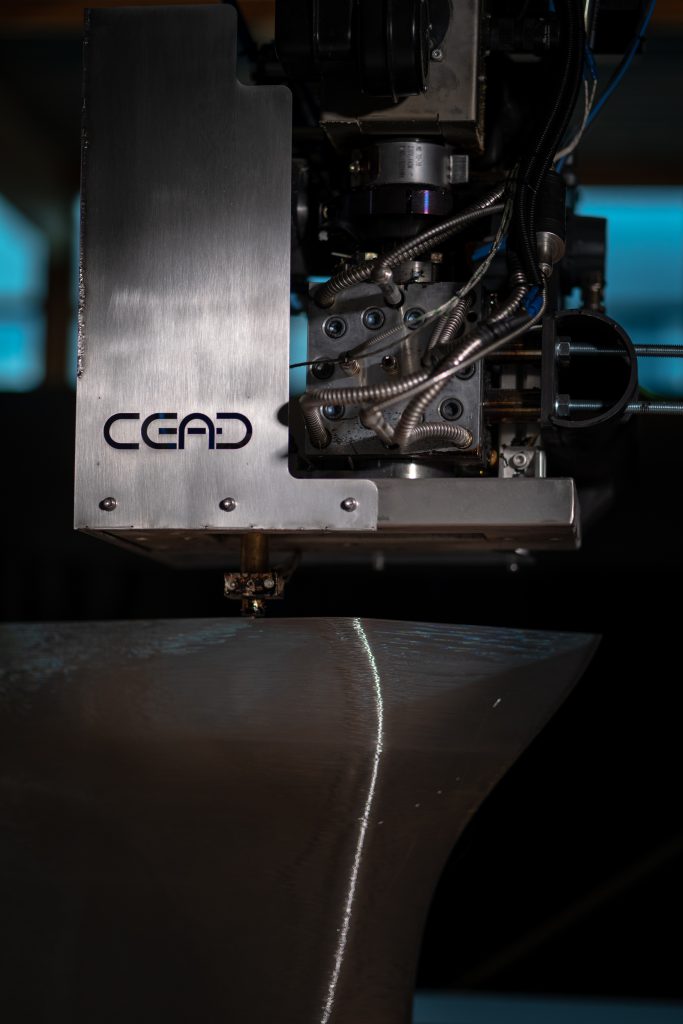

As part of the new collaboration, CEAD and DSM “open the door” to developing 3D printing processes that combine continuous fiber composites with highly filled polymers. DSM will be purchasing a 6-axis robotic 3D printer from CEAD for the purpose of material development and profile optimization. The arm is provided by Italian automation company Comau, and it is operated using Siemens software. It is also equipped with CNC milling and scanning capabilities for post processing following 3D printing.

Maarten Logtenberg, CEO of CEAD, concludes, “The relationship between the 3D-printing technology and the materials that are used in the process, are key.”

“Through this collaboration with DSM and their understanding of the materials, we are able to fully leverage the [FGF] to its full potential.”

Vote now in the 2019 3D Printing Industry Awards.

For more regular 3D printing updates subscribe to the daily 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the CEAD CFAM Prime additive manufacturing system. Photo via Gijs Lokker.