Metal additive manufacturing research has found a way to 3D print steel free from porosity. Of all the combinations and variants of modern steel, martensite shines due to its high strength, ductility, relatively low weight, and cost-effective production. The 3D printing of complex structures can have an effect on the strength and durability of any material, however, so researchers from Texas A&M University found a workaround for this.

The research team developed a set of guidelines and parameters that allow for the additive manufacturing of a low-alloy martensite (AF9628) into defect-free parts without sacrificing geometric freedom. AF9628 usually exhibits strengths greater than 1.5GPa with 10% tensile ductility, so matching this using SLM would prove to be difficult.

Metal 3D printing challenges

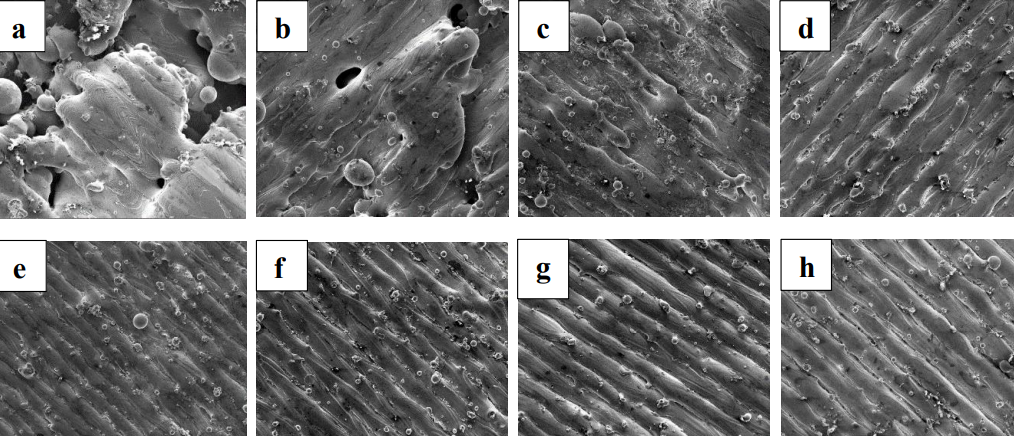

Metal powder bed fusion, while offering unparalleled design freedom, can result in the formation of defective pores in a manufactured part called porosities. According to Dr. Ibrahim Karaman, co-author of the study, porosities can sharply decrease the strength of a 3D printed part, even if the raw material is strong.

Developing a framework for AM martensite

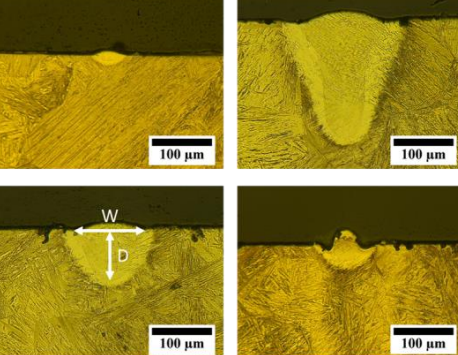

To prevent defect formation during AM, the team first chose a computationally inexpensive welding-inspired mathematical model, the Eagar-Tsai model, to predict the melt pool geometry of a single layer of martensite powder for various laser settings. They compared the predicted results of the model with actual defects from an experimental run, and tweaked the model to better predict subsequent layers. After numerous refinements and iterations, the team had tested a wide range of process parameters, and formed an SLM processing map for AF9628. A geometric criterion for precisely determining the maximum spacing between hatching lines was also developed, ensuring the team avoided defects caused by insufficient fusion between the layers.

Raiyan Seede, a graduate student and co-author of the study, explained: “Testing the entire range of laser setting possibilities to evaluate which ones may lead to defects is extremely time-consuming, and at times, even impractical. By combining experiments and modeling, we were able to develop a simple, quick, step-by-step procedure that can be used to determine which setting would work best for 3D printing of martensitic steels.”

Using their framework, the researchers 3D printed martensite with a tensile strength of 1.4 GPa and an elongation of 11%. According to the study, the tensile strength of the martensitic steel was the highest reported to date for any 3D printed alloy – an impressive feat. The research team then further developed the clever approach to process parameter refinement to also be applicable to other metals and alloys.

Karaman concludes, “Although we started with a focus on 3D printing of martensitic steels, we have since created a more universal printing pipeline. Also, our guidelines simplify the art of 3D printing metals so that the final product is without porosities, which is an important development for all types of metal additive manufacturing industries that make parts as simple as screws to more complex ones like landing gears, gearboxes or turbines.”

Further details of the study and findings can be found in the paper titled ‘An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: Densification, microstructure, and mechanical properties’. It is co-authored by Raiyan Seede, David Shoukr, Bing Zhang, Austin Whitt, Sean Gibbons, Philip Flater, Alaa Elwany, Raymundo Arroyave, and Ibrahim Karaman.

Researchers from Texas A&M University have previously delved into the science behind 3D printing technologies with a number of studies. Earlier this year, a research team from the University examined the different factors that can have an impact on the success of an FDM print, namely the diameter of the nozzle and the layer thickness. Last year, a different ensemble of researchers from the University developed bioink enabling the 3D printing of scaffolds for protein transport for therapeutic purposes.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

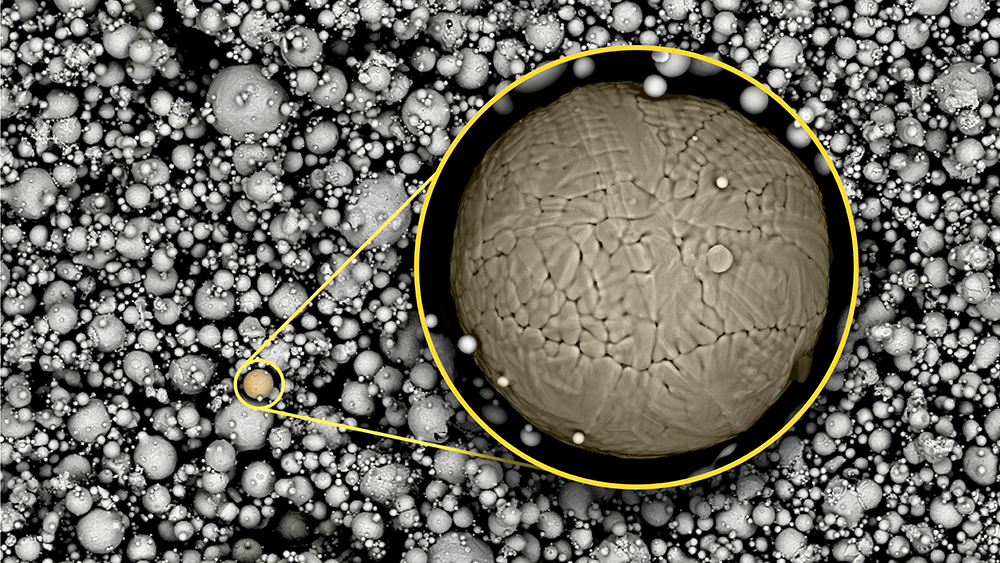

Featured image shows close up of martensite powder. Image via Raiyan Seede.