A group of international researchers has produced binder jet 3D printed geopolymer structures competitive with structural concrete for various applications.

The primary goal of the research was to 3D print metakaolin, a dehydroxylated form of the clay mineral kaolinite, without the use of cement.

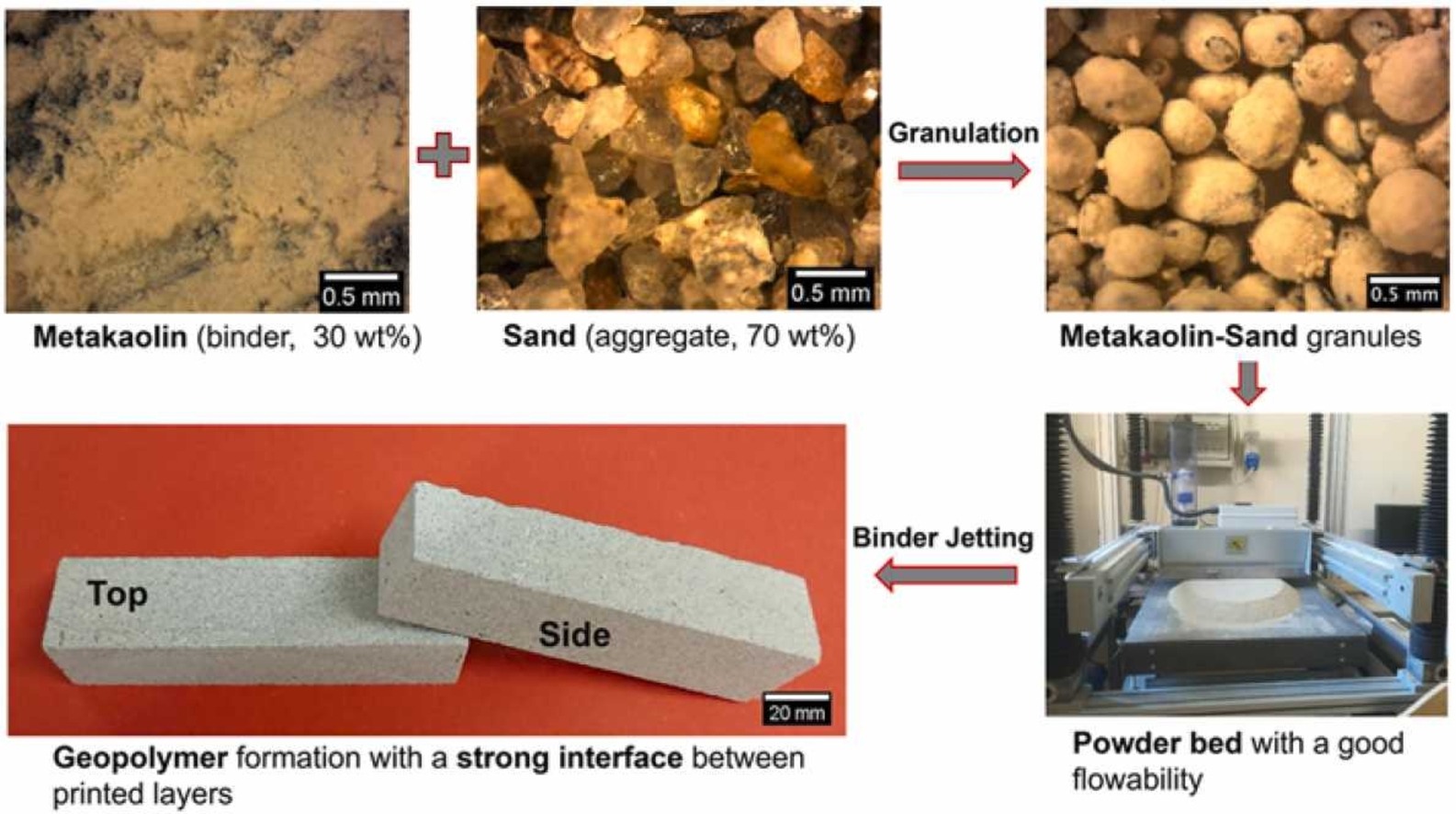

By creating a feedstock made entirely of sand and metakaolin, the team was able to produce prism-shaped geopolymer components with defect-free powder layers in what they claim is a cleaner and more sustainable production process.

Benefits of geopolymers

3D printing has been increasingly used within the construction sector in recent years, however cement manufacturing has long been associated with higher greenhouse gas emissions and energy consumption, which deteriorates the overall sustainability of 3D printed concrete structures. Cement is also subject to high autogenous shrinkage, heat of hydration, and high costs.

By comparison, geopolymers offer a fast-setting, cost-effective and eco-friendly alternative, providing enhanced fire resistance and durability compared to conventional cement composites. As such, research into 3D printing geopolymer structures able to rival conventional materials like structural concrete has garnered more attention in recent years.

Back in 2017, for instance, NTU Singapore created a geopolymer cement using waste fly ash particles produced as a by-product of the coal combustion process. The use of fly ash significantly reduced the carbon footprint of the traditional cement production process while also delivering superior heat-resistant properties to the material.

More recently in 2020, the Swinburne University of Technology and French construction firm Bouygues Travaux Publics deployed machine learning techniques to develop a stronger 3D printed geopolymer cement and a subsequent roadmap for classifying the stability of other 3D printed compounds used in the construction sector.

3D binder jetting geopolymers

The latest study in this field has emerged from an international team of researchers hailing from stone 3D printing firm Desamanera and the University of Padova in Italy, Egypt’s National Research Center, Pennsylvania State University in the US, and the Ceramic and Mineral Resources Technology Center (CETMIC) in Argentina.

The primary goal of the study was to print metakaolin without the use of cement. To achieve this, the researchers developed a granulation technique that allowed them to produce a feedstock with ‘reasonable’ flowability, made up of sand granules covered by metakaolin.

The binder jet 3D printing process allowed the researchers to take advantage of the geo-polymerization process that occurs when metakaolin reacts with an alkaline solution.

Through jetting an alkaline solution onto the powder bed, the granulation procedure allowed for a higher proportion of metakaolin, 30 wt%, in the powder bed as well as ensuring the printing of defect-free powder layers. During printing, the jetted alkaline solution reacted with the metakaolin powders present in the granules to form a geopolymer.

The group chose a large-scale, commercially available binder jet 3D printer to produce their structural geopolymer components made up of two feedstocks; one made entirely of metakaolin and sand, and the other including a small amount of commercial rapid setting cement in the powder mix.

During the study, all of the 3D printed samples were found to be water-resistant, with no significant differences in strength after seven days of exposure to water. The 3D printed geopolymer parts fabricated with 30 wt% metakaolin exhibited a compressive strength of 20 MPa, even with a 30% volume of residual porosity.

The researchers observed the 3D printed geopolymers containing only metakaolin possessed the same printing accuracy and resolution as those containing cement. According to the team, this confirmed the high reactivity of the corresponding metakaolin granules to prepare the geopolymer gel for fabricating strong, high-resolution geopolymer parts without the need for cement.

The team’s granulation technique enabled a higher wt% of fine and reactive metakaolin particles to be introduced into the powder bed to maintain the flowability of the feedstock and allow the printing of defect-free layers.

The team also found that adding rapid-setting cement to the powder bed had no effect on the printing accuracy or strength of the geopolymer parts. With no significant changes in strength observed after submerging the 3D printed geopolymer structures in water for a week, the team believes its formulation could be used in outdoor and water-interacting applications.

Further information on the study can be found in the paper titled: “Additive manufacturing of inorganic components using a geopolymer and binder jetting,” published in the Additive Manufacturing journal. The study was co-authored by H. Elsayed, F. Gobbin, M. Picicco, A. Italiano, and P. Colombo.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows formation and binder jet 3D printing process for the metakaolin and sand feedstock. Image via Additive Manufacturing.