Moving into Industry 4.0 and the age of cyber physical systems, digital construction is on the rise. Across manufacturing, the use of greener, more efficient materials is also of paramount concern.

“Considering the current importance digital construction,” states a recent study from the Singapore Centre for 3D Printing at Nanyang Technological University (NTU Singapore) “it is believed that 3D printing of geopolymer could be a breakthrough for faster and sustainable built environment.”

Choose to reuse

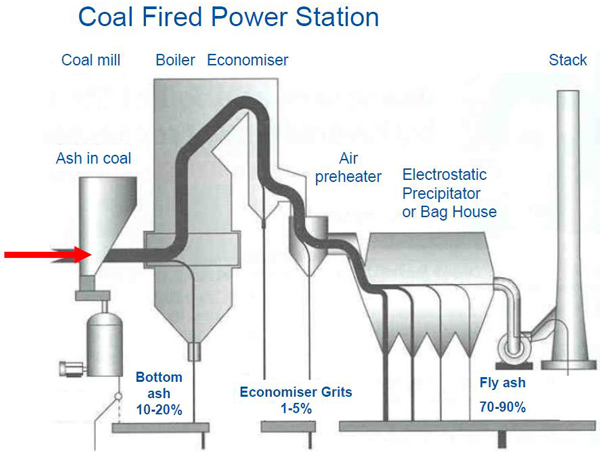

The NTU Singapore team has created a geopolymer cement using waste fly ash particles. Produced as a by-product of the the coal combustion process, fly ash is collected in filters before it reaches outlet chimneys.

In the U.S. alone around 71.1 million tons of the non-hazardous material is collected each year, and since the early 2000s, researchers have been looking at a number of applications for recycling.

As of 2005, at least half of the U.S. fly ash production is reused to make construction materials such as bricks, as a stabilizer for soil, or even as an ingredient in toothpaste.

Super strength cement

When combined with potassium hydroxide and potassium silicate, fly ash can be turned into a geopolymer that solidifies at room temperature, like Portland cement. Conversely, the alternative ingredient also significantly reduces the carbon footprint of traditional cement production process, and reinforces the material with superior heat-resistant properties.

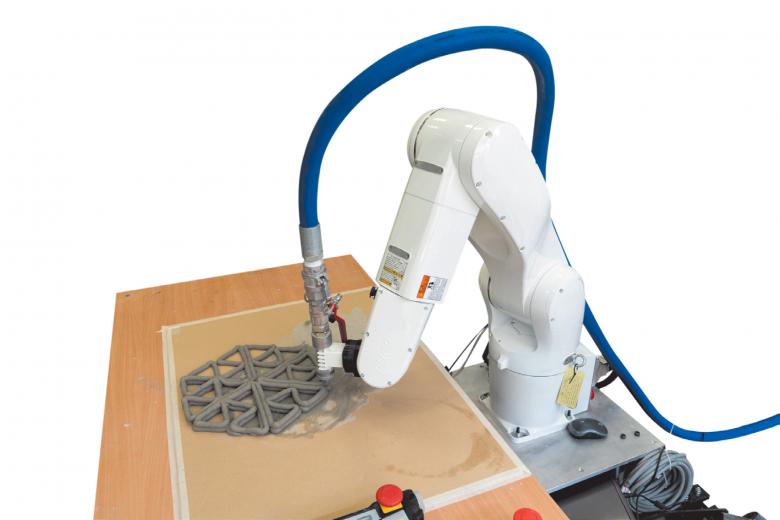

Using such a fly ash geopolymer solution, NTU Singapore researchers 3D printed the material to test mechanical properties.

When compared to a mold-cast geopolymer, NTU Singapore found that the 3D printed geopolymer had higher compression strength over the X and Z axis.

This is supported by other 3D printed construction studies, and is due to directional properties created by the deposition of layers.

The authors explain, “the mechanical properties of 3D printed geopolymer are mostly dependent of loading directions due to anisotropic nature of the printing process”.

The future is integrated

The study also identifies four key limitations to the current process of 3D printing for construction.

Considering the 3D printing of overhanging structures they say “In this case, support material can be used to handle this issue. Also, materials with rapid hardening behavior can solve this issue in some extent.”

Additionally, the authors consider possibilities for the multi-material printing of buildings, and a need for standard development, the likes of which have been preliminary outlined for construction in Dubai.

Addressing ideas that 3D printing will one day replace traditional construction altogether, conclusions state that “The future of construction is most likely to be an integrated process that allows organizations to take advantage of both conventional and additive manufacturing technologies at the same time.”

A full study of the research discussed in this article is available online in the Journal of Cleaner Production, August 2017. It is co-authored by Biranchi Panda, Suvash Chandra Paul, Lim Jian Hui, Yi Wei Daniel Tay, and Ming Jen Tan.

Find us on Facebook and Twitter for more of the latest 3D printing news and research.

Looking for jobs in engineering? Sign up to our dedicated jobs site now.

Featured image: SEM image of coal burning by-product fly ash encapsulated in resin. Image by Wikimedia Commons contributor wabeggs