Researchers from Marche Polytechnic University, Italy have 3D printed a set of isogrid panels – a type of anti-buckling structure – using fused filament fabrication. The carbon fiber reinforced polyamide panels were then subjected to a number of axial compressive loading tests and the effects of their geometric parameters on their structural integrity were investigated.

Isogrid panels in aerospace

Isogrid panels have a partially hollowed-out lattice structure characterized by a grid-like geometry of equilateral triangles. They are used to stiffen and reinforce other structures which are subjected to high axial loads, preventing them from buckling. In aerospace, isogrid panels are commonly found around propellant tanks, payload shrouds, and other pressure vessels to stop them from rupturing.

Initially, isogrids were made of aluminum but advancements in material science and automated fiber placement technology have made it possible to manufacture them out of composites, which are more suited to the harsh conditions of aerospace applications. The researchers cite a number of geometric parameters that can contribute to the effectiveness of an isogrid panel, including rib thickness, rib width, and cell height.

Carbon fiber reinforced polyamide

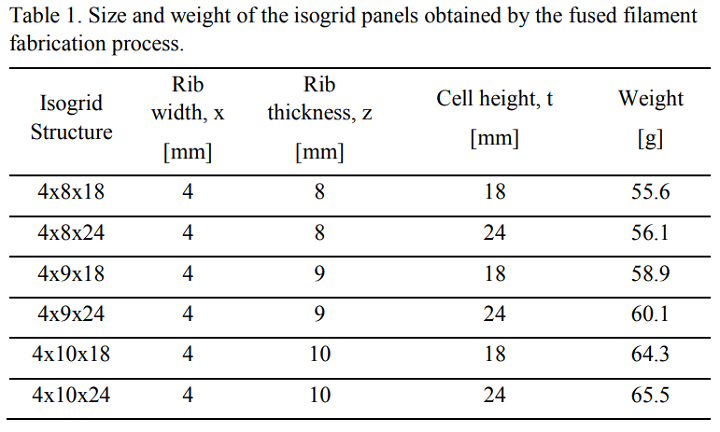

The researchers set out with the goal of testing the suitability of 3D printing for the application while evaluating the quantitative effects of the geometric parameters. The team used a high-performance Roboze One+400 3D printer to manufacture the isogrid panels. The material used was CarbonPA, consisting of 80% polyamide and 20% short carbon fibers by weight. The panels had an infill density of 100%, giving them the mechanical strength of a typical aluminum alloy.

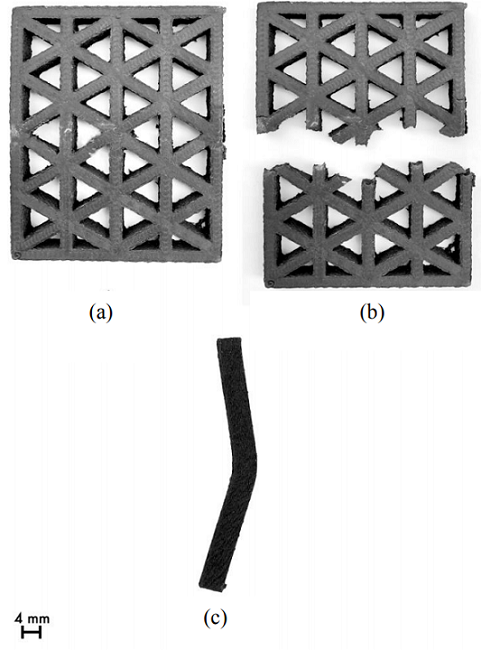

As in an equilateral triangle, the team oriented the ribs at 60° and 120°. Each panel had a constant rib width of 4mm but varying rib thicknesses and cell heights to isolate the effects of those two parameters. The panels were compressed until the point of fracture using a hydraulic testing machine and the axial forces and displacements were recorded.

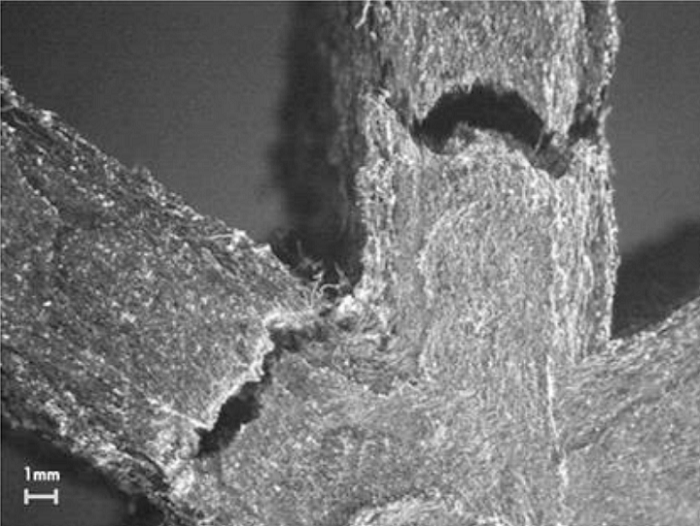

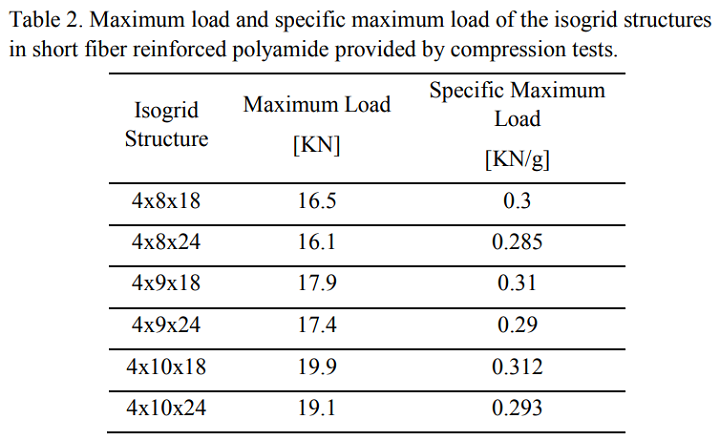

The team determined that the dominant failure mechanism in each of the panels was global buckling extending to the whole structure. This was as a result of the structure’s relative thinness being greater than that of the individual ribs. The maximum compressive load until the point of buckling increased with rib thickness but decreased with cell height. The results demonstrated that 3D printing could be used to manufacture composite isogrid panels and the resulting structures could be used to assess individual geometric parameters, furthering research in the field of anti-buckling structures.

Further details of the study can be found in the paper titled ‘Manufacturing of Isogrid Composite Structures by 3D Printing’. It is co-authored by Archimede Forcellese, Valerio di Pompeo, Michela Simoncini, and Alessio Vita.

The compressive strength of load bearing parts is of great interest to material scientists and mechanical engineers, especially when concerned with industrial applications. Researchers in Romania have recently released a study investigating the mechanical behaviour of 3D printed hollow PLA spheres under axial compression. Much like the present study, a number of the spheres’ parameters were individually tested to determine their effects on the strength of the parts. Elsewhere, in Slovakia, researchers have increased the strength of a neat PETG filament by reinforcing it with carbon fiber and expanded graphite additives.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows isogrid panel structure. Photo via Isogrid Composites.