In a microscopic method not unlike sieving, researchers at Queen Mary University of London (QMUL) have developed a new method for 3D printing soft matter.

Named 3D Electrophoresis-Assisted Lithography (3DEAL), the process can sort molecules to make biomimetic hydrogel environments that support tissue growth, or pose an alternate method for screening drugs.

Patterning proteins

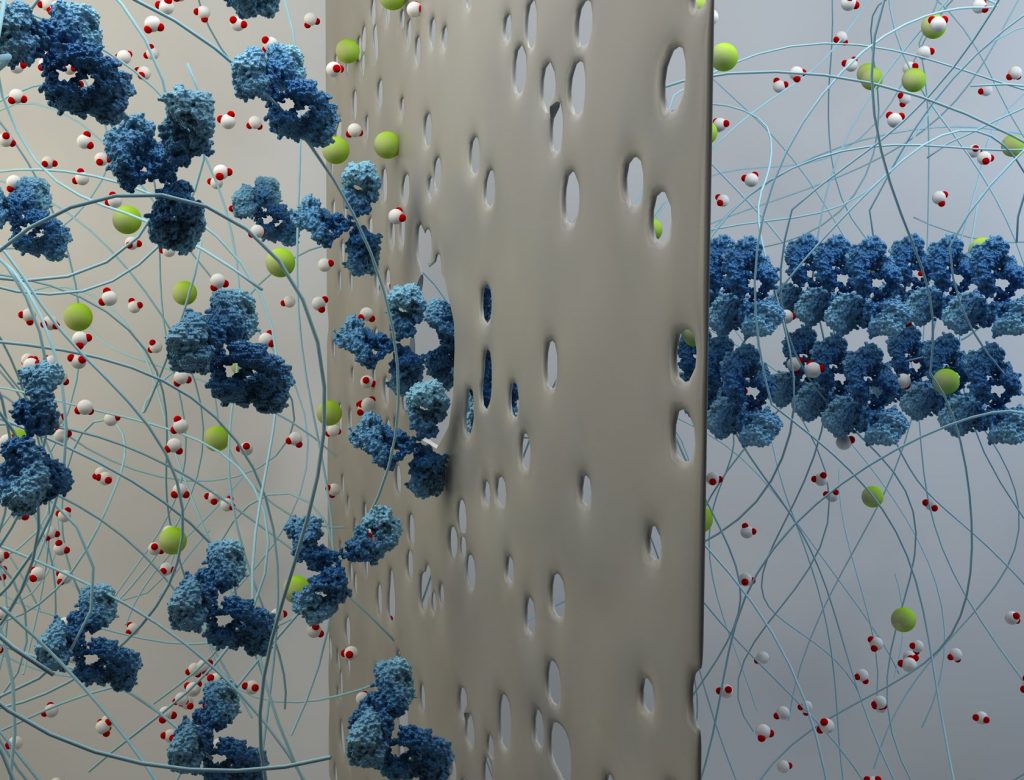

3DEAL is a patterning process that relies on an electrical charge and porous mask to sort protein molecules. The process takes place inside a small capsule, one half containing a preset hydrogel, the other half containing the protein to be patterned throughout the gel.

The porous mask sits in between these two halves, and is patterned with holes that dictate the arrangement of protein molecules.

After around 2 hours of preparation, the capsule is slotted between two liquid baths, one containing a positive anode, and the other a negative cathode. A live electrical charge encourages protein particles to move through the porous mask and into the hydrogel.

The finished product is a small semi solid tube, with a thin vessel-like structure running through it.

Robust, simple and low-cost

Professor Alvaro Mata, is lead reseracher on the 3DEAL project at QMUL’s School of Engineering and Materials Science. Describing the concept behind the project Professor Mata explains, “The human body is largely made up of anisotropic, hierarchical, and mostly three dimensional structures,”

“New ways to fabricate environments that can recreate physical and chemical features of such structures would have important implications in the way more efficient drugs are developed or more functional tissue and organ constructs can be engineered.”

Gastón Primo, a PhD student under the supervision of Professor Mata an co-author of the study adds, “A major advantage of the technique is its robustness and cost-effectiveness. It is simple and can be used with different types of readily available hydrogels and be patterned with different types of molecules.”

Further reading

Colloidal self-assembly is another method that has been investigated for its potential to tune materials on a molecular level. In this method, molecules in a liquid are squashed together like strips of play dough.

For more information on the 3DEAL technique, you can read a full paper on the technique in the journal Advanced Functional Materials. It is co-authored by Juan P. Aguilar, Michal Lipka, Gastón A. Primo, Edxon E. Licon-Bernal, Juan M. Fernández-Pradas, Andriy Yaroshchuk, Fernando Albericio, and Alvaro Mata.

Featured image shows fluorescent protein patterns connected to hydrogels made by 3DEAL. Photo via QMUL