Self-assembly is the ultimate aim of new research, and presents a future vision of 3D printing at a molecular level.

The concept describes how particles can be programmed to arrange themselves into virtually any shape possible. The resulting microstructures formed would be capable of performing tasks the way cells do, and even create the basis of larger constructs.

Extended from this concept, pioneers such as Eric Drexler have written at length about molecular nanotechnology and the ability to create nano-machines – which in turn can build larger devices.

Now “patchy particles”, created by a team of scientists at New York University (NYU), are making the dream of molecular “3D printing” a reality.

Spherical in shape with a liquid core, patchy particles are 10 – 100 times smaller than a human cell. Likened to LEGO bricks, the particles can combine to form more complex shapes and effectively build matter from the bottom up.

Engines of creation

Although the research focuses on particles that are larger than a micron, and therefore do not meet the definition of nanotechnology – there is an interesting proximity. In particular the concept of building matter “from the bottom up” was first introduced by Eric Drexler in his seminal text Engines of Creation: The Coming Era of Nanotechnology.

Drexler’s vision of nanotechnology faced some early challenges, however with government agencies such as DARPA now actively financing concepts such as Atomically Precise Manufacturing (APM) – “the production of materials, structures, devices, and finished goods in a manner such that every atom is at its specified location relative to the other atoms, and in which there are no defects, missing atoms, extra atoms, or incorrect (impurity) atoms”- it would seem technology is finally beginning to catch up with Drexler’s ideas.

Patchy particles

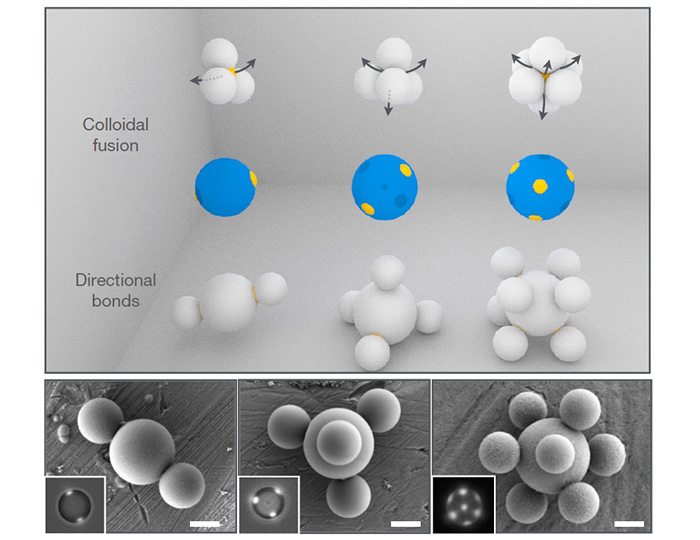

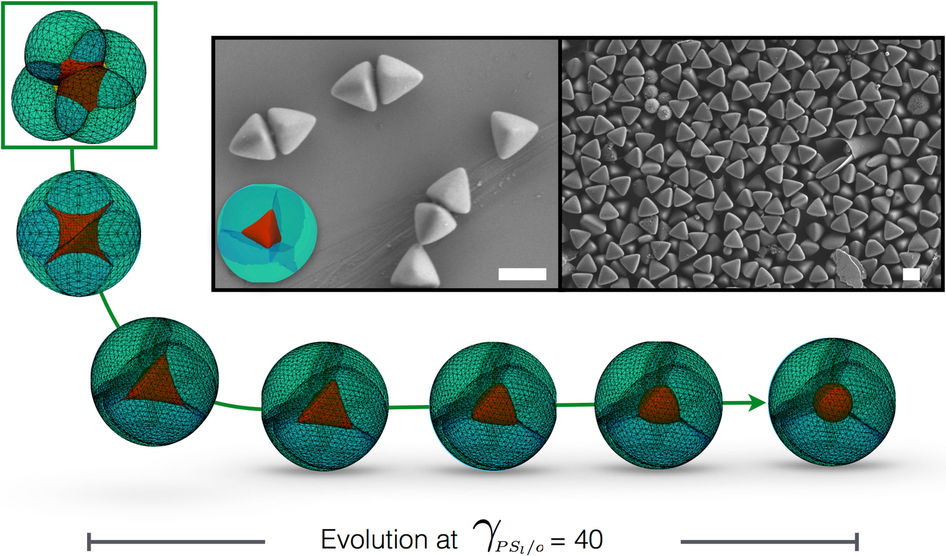

Patchy particle spheres are made from smaller, triangular particles that are in effect “squashed” together like scraps of play dough. The tricky process of making the particles is called colloidal fusion.

To start, the insoluble traingular particles are suspended throughout a liquid. By applying coordination dynamics and wetting forces, the particles are pushed into contact with one another to make a solid cluster with a liquid core.

The process is made possible by “Surface Evolver” software specially developed by NYU to simulate the process, and then realized by in-lab experiments.

Self-assembling sandcastles

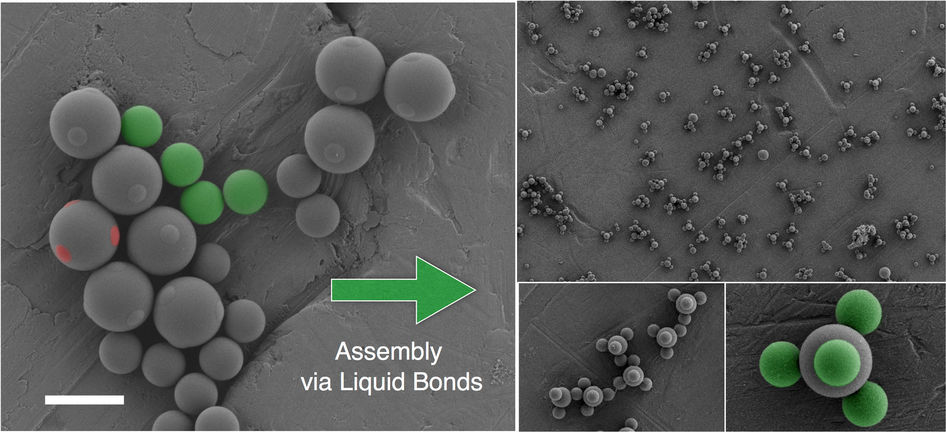

In colloidal fusion, two types of patchy particles are created. First, the kind that use the exposed liquid patches to form bonds with neighbouring particles.

And second, those that form nodules of liquid on the surface, that can connect to form more complex 3D shapes.

To form permanent bonds between the particles, a plasticizer is added and the material is cured.

Stefano Saccana, assistant professor of chemistry at NYU explains the process as follows, “Imagine that you want to build a castle, but instead of handpicking the bricks and patiently connecting them one by one, you simply shake the box of pieces so that they magically connect to one another in forming a full-featured castle.”

Changing the face of 3D printing

Saccana also believes that “Colloidal self-assembly has the potential to revolutionize 3D printing.” He suggests that, “This could be achieved by not merely by further reducing the size of the printed architectures, but also by allowing us to ‘print’ functional architectures.”

Giving the example of a model car, Saccana adds, “using colloidal self- assembly, you could print a car that is a fraction of a millimetre and that could someday actually run!”

Examples of the kind of applications this would facilitate can so far be found in medical research, such as the bacteria-powered micromotors at Sapienza University of Rome, or self-actuated microswimmers developed at the Max Planck Institute for Intelligent Systems.

More about information about the research discussed in this article, can be found in the letter Patchy particles made by colloidal fusion published online by nature. It is co-authored by NYU’s Zhe Gong, Theodore Hueckel, and Stefano Sacanna, and Gi-Ra Yi of Sungkyunkwan University in South Korea.

For more articles discussing the future of 3D printing subscribe to our newsletter and find our articles on Twitter and Facebook.

Get hired or find candidates by registering your research expertise on our 3D printing jobs site here.

Featured image shows the colloidal fusion of triangular pyramid particles into a spherical “patchy particle.” Moving .gif image via Nature Letters/Patchy particles made by colloidal fusion, supplementary materials.